Microshift shifter is "overshifting". Is Shimano any better?

#1

Junior Member

Thread Starter

Microshift shifter is "overshifting". Is Shimano any better?

I've spent months trying to solve an issue with the rear shifting on my wife's bike. When downshifting from cog #3 to #2 on the rear cassette (inward from the 3rd-largest cog to 2nd-largest cog), the chain will temporarily be grabbed by the largest, innermost cog (#1) before dropping (unpredictably and jarringly) back out to the correct #2 cog.

Here is a video. I do two cycles in and out, so you can see the improper shift happen twice. You can also click the video’s settings->Playback Speed to run it at half-speed.

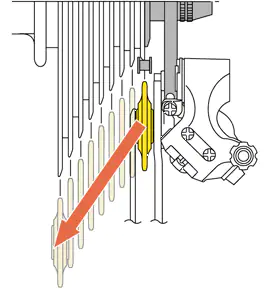

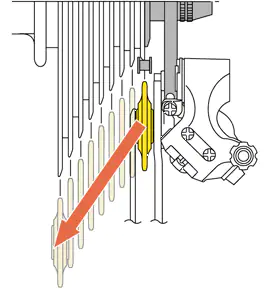

I think multiple factors are contributing to the problem, but one of the biggest seems to be “overshifting”, which is the term I’m using to describe the movement of the derailleur pulleys inboard past the targeted cog position before settling back out in line with the cog.

Here is a second video, with the chain off, which makes it easier to focus precisely on the derailleur movement. Again, you can slow it down to half-speed to make the “overshift” even more-obvious. I’m making a particular effort to push the lever the absolute minimum amount necessary to get it to click into the next indexed position. The final inboard shift doesn’t display the same amount of overshift because that’s where it’s stopped by the limit screw.

This seems to be a property inherent to indexed shifters, though I’m not sure if it’s an intended feature (to make downshifts happen faster/more-reliably?), or an undesirable side-effect. Anyone know? I can see it in this Park Tool video where on the downshifts, the bare cable advances slightly past the overlaid white lines before settling back (and in contrast, on upshifts it falls precisely to the final position, which is the same way my shifter works). Jump to 1:56; sorry, it seems like the embed doesn't allow me queue up the video to that point:

Unfortunately I don’t have other bikes/components to compare (my own bike also uses MicroShift shifters that I long-ago switched to friction-mode), and the full housing on my wife’s derailleur cable prevents me from visually comparing with the Park Tool video.

At the derailleur itself, on my wife’s bike, the pulley moves nearly one whole extra cog-spacing inboard (maybe 1-2 cog-thicknesses less) before settling back. This qualitatively seems like “a lot” to me, but I’ve never really looked at it before, so I don’t know if this is unusual. So that’s why I’m looking to the wisdom and experience of the group here.

My inclination is to replace the shifter and see if that’s sufficient to stop the problem. The current shifter is a Microshift SL-T09 9-speed thumb shifter. We like the simplicity and (theoretical!) durability of the shifter design (vs. trigger shifters, which don’t easily fit on her Koga Denham flat handlebar).

HOWEVER! If I run my own 11-34t cassette on her bike, the problem occurs much less frequently. So there must be something about that big 36t cog that, when combined with the overshift, makes it easier for it to grab the rising chain away from its neighboring cog when it isn’t supposed to.

My wife isn’t ready to give up her low gearing that comes with that 36t cog, so that’s why I wonder if switching to the ADVENT system that’s specifically designed for huge cogs (it can go up to 46t) would be the safest choice.

I'm a reasonably-experienced self-taught bike mechanic (I built up both my wife's and my own touring bikes that we've been living off of for the last 18 months), so I'm fairly confident that I've worked through the obvious possibilities, but I'm certainly open to any other ideas/solutions!

Here is a video. I do two cycles in and out, so you can see the improper shift happen twice. You can also click the video’s settings->Playback Speed to run it at half-speed.

I think multiple factors are contributing to the problem, but one of the biggest seems to be “overshifting”, which is the term I’m using to describe the movement of the derailleur pulleys inboard past the targeted cog position before settling back out in line with the cog.

Here is a second video, with the chain off, which makes it easier to focus precisely on the derailleur movement. Again, you can slow it down to half-speed to make the “overshift” even more-obvious. I’m making a particular effort to push the lever the absolute minimum amount necessary to get it to click into the next indexed position. The final inboard shift doesn’t display the same amount of overshift because that’s where it’s stopped by the limit screw.

This seems to be a property inherent to indexed shifters, though I’m not sure if it’s an intended feature (to make downshifts happen faster/more-reliably?), or an undesirable side-effect. Anyone know? I can see it in this Park Tool video where on the downshifts, the bare cable advances slightly past the overlaid white lines before settling back (and in contrast, on upshifts it falls precisely to the final position, which is the same way my shifter works). Jump to 1:56; sorry, it seems like the embed doesn't allow me queue up the video to that point:

Unfortunately I don’t have other bikes/components to compare (my own bike also uses MicroShift shifters that I long-ago switched to friction-mode), and the full housing on my wife’s derailleur cable prevents me from visually comparing with the Park Tool video.

At the derailleur itself, on my wife’s bike, the pulley moves nearly one whole extra cog-spacing inboard (maybe 1-2 cog-thicknesses less) before settling back. This qualitatively seems like “a lot” to me, but I’ve never really looked at it before, so I don’t know if this is unusual. So that’s why I’m looking to the wisdom and experience of the group here.

My inclination is to replace the shifter and see if that’s sufficient to stop the problem. The current shifter is a Microshift SL-T09 9-speed thumb shifter. We like the simplicity and (theoretical!) durability of the shifter design (vs. trigger shifters, which don’t easily fit on her Koga Denham flat handlebar).

- So the first obvious replacement would be Shimano Dura-Ace bar-end shifter grafted onto a Paul Thumbie. But if the Shimano shifter exhibits the same amount of overshift, I’d rather not waste all that money just to learn that. So: I would be very thankful if any Shimano bar-end owners here could report on what their “overshift” looks like!

- A second option would be a simple replacement with a new Microshift SL-T09 (or even just its indexing parts). I’ve disassembled, cleaned, and reassembled the existing shifter, and didn’t find any obvious defects, but it’s certainly possible that the little balls and the indexing plate have worn to somehow cause “overshift” beyond spec. (the current shifter is only(?) three years old, with ~8000 miles on it, though we’re both high-frequency shifters).

- A third option would be to switch to Microshift’s ADVENT line, with an 11-42t cassette.

HOWEVER! If I run my own 11-34t cassette on her bike, the problem occurs much less frequently. So there must be something about that big 36t cog that, when combined with the overshift, makes it easier for it to grab the rising chain away from its neighboring cog when it isn’t supposed to.

My wife isn’t ready to give up her low gearing that comes with that 36t cog, so that’s why I wonder if switching to the ADVENT system that’s specifically designed for huge cogs (it can go up to 46t) would be the safest choice.

I'm a reasonably-experienced self-taught bike mechanic (I built up both my wife's and my own touring bikes that we've been living off of for the last 18 months), so I'm fairly confident that I've worked through the obvious possibilities, but I'm certainly open to any other ideas/solutions!

- Cable tension adjustment: shifting between all the other cogs never misfires (unless I adjust the tension such that the 3->2 shift doesn't overshift; in that case, all the other downshifts have trouble actually making it to their intended gear).

- Derailleur B-screw: I’ve adjusted it to both extremes (away from the spec’ed position I normally have it at), and it doesn’t seem to have much effect either way.

- Derailleur hanger: the derailleur hanger actually was significantly out-of-whack, but straightening it didn't seem to change anything in the shifting behavior (it was actually bent outward, which, combined with its lack-of-influence in the shifting issue, suggests to me that it had somehow been like that since I built up the bike; I never actually checked it after installing the hanger/derailleur onto the frame).

- Cable/housing: this is the one item I haven’t actually process-of-eliminated. I have removed, lubed, and reinserted the cable in the (full-length) housing, and it seems to slide freely. And the quick and reliable upshifting, when the derailleur spring pulls the cable back its way, suggests there isn’t a lot of resistance there. But, I haven’t actually replaced the ~3-year-old housing.

Last edited by Neil G.; 02-08-23 at 12:17 PM.

#2

Senior Member

Join Date: Apr 2011

Posts: 7,082

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4418 Post(s)

Liked 1,569 Times

in

1,031 Posts

The cable housing to the RD is way too short. It should be a big gentle curve extending 4" behind the barrel adjuster.

Likes For Kontact:

#3

I'm good to go!

Join Date: Jul 2017

Location: Mississippi

Posts: 15,002

Bikes: Tarmac Disc Comp Di2 - 2020

Mentioned: 51 Post(s)

Tagged: 0 Thread(s)

Quoted: 6199 Post(s)

Liked 4,816 Times

in

3,323 Posts

The DR is going to over shift a tad just to get that chain to the correct cog quicker. Though it shouldn't over shift to the extent the chain grabs the next cog. Even my Shimano DR's go a small bit further initially then relax after the click is completed. I even think Di2 does the same, but I'd have to look to be sure.

You say you have full length cable housing. You mean it goes all the way from the shifters to the DR in it's cable housing? That might be an issue there because some of the cable pull is being lost in the compression of the housing along it's entire length forcing the barrel adjuster or in-line adjuster to be set to shorten the cable more than it should be. They don't really adjust cable tension, that's a function of the spring on the DR itself that we don't have any control over.

You say you have full length cable housing. You mean it goes all the way from the shifters to the DR in it's cable housing? That might be an issue there because some of the cable pull is being lost in the compression of the housing along it's entire length forcing the barrel adjuster or in-line adjuster to be set to shorten the cable more than it should be. They don't really adjust cable tension, that's a function of the spring on the DR itself that we don't have any control over.

#4

Senior Member

I think exceeding the compatibility limit is the problem here. As I'm watching your videos I can see the derailleur overshifting as designed, unfortunately that 36t cog is much bigger than the 2nd position and the chain is catching it where the design intended a smaller cog to be present.

Normally you would be able to solve this by fiddling with the B-screw but my (limited) experience with low-profile Shadow derailleurs like yours is they don't respond much to that trick. I'd get the Advent, it's a great system I've used before and if the rider likes the 36t she's going to love the 42.

Normally you would be able to solve this by fiddling with the B-screw but my (limited) experience with low-profile Shadow derailleurs like yours is they don't respond much to that trick. I'd get the Advent, it's a great system I've used before and if the rider likes the 36t she's going to love the 42.

#5

Senior Member

Likes For Joe Remi:

#6

Senior Member

Join Date: Jul 2015

Location: NW Oregon

Posts: 2,975

Bikes: !982 Trek 930R Custom, Diamondback ascent with SERIOUS updates, Fuji Team Pro CF and a '09 Comencal Meta 5.5

Mentioned: 15 Post(s)

Tagged: 1 Thread(s)

Quoted: 1299 Post(s)

Liked 739 Times

in

534 Posts

looks like that "simple" shifter is simply WAY overshifting on the 3-2-1-2 move.. maybe it's time to remove the "simple" and replace them with trigger shifters from Shimano.... or hope to get a microshift thumbie that works better than the defective one on your wife's bike. ;-)

i'd go with the Shimano triggers and not worry about them for a decade of more....many pairs available for under $40, shipped... installation not included.

also... do a careful inspection of her Cassette to see if there is any deviation from flat/true.... even a single bent tooth can cause havoc.

i'd go with the Shimano triggers and not worry about them for a decade of more....many pairs available for under $40, shipped... installation not included.

also... do a careful inspection of her Cassette to see if there is any deviation from flat/true.... even a single bent tooth can cause havoc.

Last edited by maddog34; 02-08-23 at 04:06 PM.

#7

Junior Member

Thread Starter

The DR is going to over shift a tad just to get that chain to the correct cog quicker. Though it shouldn't over shift to the extent the chain grabs the next cog. Even my Shimano DR's go a small bit further initially then relax after the click is completed. I even think Di2 does the same, but I'd have to look to be sure.

You say you have full length cable housing. You mean it goes all the way from the shifters to the DR in it's cable housing? That might be an issue there because some of the cable pull is being lost in the compression of the housing along it's entire length forcing the barrel adjuster or in-line adjuster to be set to shorten the cable more than it should be. They don't really adjust cable tension, that's a function of the spring on the DR itself that we don't have any control over.

#8

Senior Member

I would agree that the overshift seems a tad excessive. As the other person said a Shimano trigger will probably match the geometry more precisely than the Microshift you're using, but I still think exceeding capacity with a Shadow derailleur is exacerbating the problem.

#9

Junior Member

Thread Starter

So I dug more into the Shimano specs, and now I'm fully convinced that I'm not actually exceeding the derailleur spec. Not that approaching the edges of the spec isn't contributing to the problem, but it can't be the primary factor.

For posterity, here are the details of what I found in my digging through years of PDFs at https://productinfo.shimano.com/#/archive

2007: RD-772 (the rear derailleur on the bike) is introduced. At this time, 11-34t is the max range 9-speed cassette that Shimano makes, so that's what they put as the max compatibility; they simply didn't test it with anything else.

2009: The Compatibility Chart shows that CS-HG61-9 (bh) 12-36t cassette is introduced, along with derailleur RD-M592, a downcosted (Deore) version of Deore XT RD-M772. It declares RD-M772 (along with RD-M592, and the XTR and Saint versions) compatible with the new 12-36t cassette.

2009: Separately, the rear derailleur Technical Service Instructions PDF I linked above documenting the 11-34t limit for RD-M772 (and the 12-36t limit for RD-M592) is published, and never again updated. While looking at this doc alone could lead one to believe that lower-end trickle-down RD-M592 was somehow uniquely capable of handling a bigger cog than its more-expensive brethren, I interpret this to mean that Shimano just copied over the old compatibility spec for the old derailleurs when they added RD-M592, and forgot to update them to take into account the existence of the new 12-36t cassette (or this doc was updated before they performed compatibility testing).

2017: Finally, CS-HG400-9 (cb), the first 11-36t 9-speed cassette, and the one I installed on the bike, is introduced. The Compatibility Chart is updated to show that RD-M772 (and its brethren) are also compatible with this new cassette.

Good to know that my B-screw experience isn't unusual in this case. And nice to hear that the Advent is good. Trouble is I'm not sure if the 42t will actually be helpful; she has a 22t up front, for a 16.7 gear-inch low gear already (4.5mph at her 90rpm cadence) I don't know what she'd actually do with a 14.3 gear-inch low (3.8mph) except fall over!

Oh, and thanks for saving me from having to answer about the cable routing! It seems like the RD-M771 (pre-Shadow) derailleur (and its brethren) had the big-loop-around routing AND a legit 34t limit, so the big loop would actually be a quick way to spot an incompatibility!

For posterity, here are the details of what I found in my digging through years of PDFs at https://productinfo.shimano.com/#/archive

2007: RD-772 (the rear derailleur on the bike) is introduced. At this time, 11-34t is the max range 9-speed cassette that Shimano makes, so that's what they put as the max compatibility; they simply didn't test it with anything else.

2009: The Compatibility Chart shows that CS-HG61-9 (bh) 12-36t cassette is introduced, along with derailleur RD-M592, a downcosted (Deore) version of Deore XT RD-M772. It declares RD-M772 (along with RD-M592, and the XTR and Saint versions) compatible with the new 12-36t cassette.

2009: Separately, the rear derailleur Technical Service Instructions PDF I linked above documenting the 11-34t limit for RD-M772 (and the 12-36t limit for RD-M592) is published, and never again updated. While looking at this doc alone could lead one to believe that lower-end trickle-down RD-M592 was somehow uniquely capable of handling a bigger cog than its more-expensive brethren, I interpret this to mean that Shimano just copied over the old compatibility spec for the old derailleurs when they added RD-M592, and forgot to update them to take into account the existence of the new 12-36t cassette (or this doc was updated before they performed compatibility testing).

2017: Finally, CS-HG400-9 (cb), the first 11-36t 9-speed cassette, and the one I installed on the bike, is introduced. The Compatibility Chart is updated to show that RD-M772 (and its brethren) are also compatible with this new cassette.

Normally you would be able to solve this by fiddling with the B-screw but my (limited) experience with low-profile Shadow derailleurs like yours is they don't respond much to that trick. I'd get the Advent, it's a great system I've used before and if the rider likes the 36t she's going to love the 42.

Oh, and thanks for saving me from having to answer about the cable routing! It seems like the RD-M771 (pre-Shadow) derailleur (and its brethren) had the big-loop-around routing AND a legit 34t limit, so the big loop would actually be a quick way to spot an incompatibility!

#10

Junior Member

Thread Starter

looks like that "simple" shifter is simply WAY overshifting on the 3-2-1-2 move.. maybe it's time to remove the "simple" and replace them with trigger shifters from Shimano.... or hope to get a microshift thumbie that works better than the defective one on your wife's bike. ;-)

I'm honestly not too much of a "simple is better" retrogrouch (or at least I didn't used to be

); way back in 2003, when such things were far more heretical, and 16 years before the Trek 520 left the bar-end shifters behind, I kept the STI shifters that came with the Cannondale touring bike I bought and thought they were great. When I built up my next touring bike, I wasn't willing to give up always-at-my-fingers shifting but wanted easier low-gearing compatibility, so I went with Gevenalle (drop-bar brakes with MicroShift thumb shifters grafted onto the front) and absolutely loved the functionality.

); way back in 2003, when such things were far more heretical, and 16 years before the Trek 520 left the bar-end shifters behind, I kept the STI shifters that came with the Cannondale touring bike I bought and thought they were great. When I built up my next touring bike, I wasn't willing to give up always-at-my-fingers shifting but wanted easier low-gearing compatibility, so I went with Gevenalle (drop-bar brakes with MicroShift thumb shifters grafted onto the front) and absolutely loved the functionality.Then when building up my wife's bike, I did simply buy some basic Shimano flat-bar trigger shifters, siince that's what she was used to and I knew they'd be plenty reliable. But they literally didn't fit on the handlebars, so I had to come up with a different solution. One guiding principle I had was to make our bikes have as many parts interchangeable between the two of them as possible, so getting her Microshift thumb shifters that matched mine was an obvious choice.

But thanks for making me think through that, because it shows that getting Shimano Dura-Ace bar-end shifters would really only make sense if retrogrouchiness was the primary goal, since although they'd be a similar design as my shifters, they wouldn't actually be compatible with each other anymore. Maybe I can put more time into trying to find a trigger shifter model that would be compatible with her handlebars.

Good call about bent cogs; given how much I've been looking at her cassette I probably would have noticed if anything was out of whack, but I haven't explicitly thought of that issue, so I'll take a look!

#11

Senior Member

Of course it's possible you just have a sloppy, worn out XT mech and this is what a sloppy, worn out XT mech does. The 3-year-old shifter has 8000 miles on it and your derailleur is easily at least 10-years-old. Time for new stuff!

#13

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,099

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4211 Post(s)

Liked 3,881 Times

in

2,316 Posts

Back in the day of friction 5 cog systems a lot of overshift was generally needed as tooth and chain link shaping was not as "engineered" as these days. As chisel tooth and twist tooth profiles and shaped chain links became the norm the amount of over shift reduced to the point where many early SIS systems could (note not always) shift with "undershift" lever movement. Shimano was well known for seeking this. These days with more guide pulley/cog underside gaps (as cage/pulley designs, cog ranges and cable lengths have changed) more overshift is back to the norm, especially as wear builds up.

Check the guide pulley side play (any cocked play of the pulley indicates wear) as this can affect shifting more than many look for. Any other der pivot slop only adds the need for over movement of the guide pulley that can quickly "swing into" an overshifting result. The more tightly the cogs are place together (as in more cog counts in general) the greater any wear or slop affects this. Andy

"The Dancing Chain" (by Frank Berto) is a very good primer to both the history of der systems as well as to what affects their shifting performance.

__________________

AndrewRStewart

AndrewRStewart

#14

Senior Member

Join Date: Apr 2011

Posts: 7,082

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4418 Post(s)

Liked 1,569 Times

in

1,031 Posts

OP, how did you correctly straighten the hanger? A gauge is required.

And do you have the cable on the correct side of the fixing bolt?

#15

I'm good to go!

Join Date: Jul 2017

Location: Mississippi

Posts: 15,002

Bikes: Tarmac Disc Comp Di2 - 2020

Mentioned: 51 Post(s)

Tagged: 0 Thread(s)

Quoted: 6199 Post(s)

Liked 4,816 Times

in

3,323 Posts

Yeah, there is no exposed cable anywhere between the shifter and the derailleur. Both of our bikes are like that, to minimize the opportunities for contamination to get inside. But interesting thought on the negative effects that might have, I'll have to think on that some more. And yeah, bad wording on my part saying "cable tension" for what is really "housing length adjustment".

How about your chain? According to Park Tools, 8 and less speed chains are 7mm wide. 9 is 6.5 to 7 mm wide. Will .5 mm (0.0156 inch) or a tad more than 1/64th make a difference? Don't know. Do you have some accurate calipers and can measure your chain on both bikes. Possibly that little bit might enable the chain to grab that cog.

Though in the video with it not moving the spacing between those cogs looks off, but that is likely just the eye, camera angle and video clarity.... as well as cassette cleanliness! <grin>

I haven't looked at the spec's, but don't ignore them. While some things might work well out of spec on one bike, another bike with slight differences it might not work well at all.

Consider all the differences between the two bikes. And all the other suggestions by others seem reasonable.

#16

Senior Member

Join Date: Jul 2005

Location: Boulder County, CO

Posts: 4,398

Bikes: '80 Masi Gran Criterium, '12 Trek Madone, early '60s Frejus track

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 514 Post(s)

Liked 451 Times

in

339 Posts

Shimano-style shfiters are engineered and manufactured to pull the same length of cable per click. This never changes. Check your hanger alignment and make sure the cable is routed correctly into the pinch bolt. If you don't have the alignment tool, your local bike shop can do the alignment and adjust your limit screws and cable tension for $20. It looks like your low limit screw is a little on the loose side, too.

#17

Junior Member

Thread Starter

Ok, taking a lot of your advice and ideas, I’ve done a bunch more work and still don’t have perfect shifting, but I’ve certainly learned a lot more!

First, an answer to the title of this thread: Shimano DEFINITELY does much less overshifting than my current Microshift shifter. In fact, it (at least, the cheap Altus SL-M2010 trigger shifter I bought, I haven't tested the Shimano bar-ends) exhibits ZERO overshifting. It’s actually a little freaky to see how the derailleur sticks precisely where it’s pushed to after each click and doesn’t settle back at all. I have no idea if this is standard across the brand (it seems unlikely given the “settling back” of the cable shown in the Park Tool video I posted, which likely used a Shimano shifter), but it at least shows that significant variation exists across the universe of shifters. Here’s video of the Shimano, followed by my original Microshift video so you can see the stark difference:

Due to that lack-of-overshift, it does seem like the Shimano relies a lot more on the “engineered” cogs/chain (as described by Andrew here). So that makes shifting to a larger cog a bit slower than the Microshift, because the wheel has to spin around enough for the chain to find a place to climb up the cog. In contrast, the Microshift’s overshifting just yanks the chain so far that it doesn’t really need any help from the cog surface.

Backing up here’s everything I’ve done/replaced since last time:

And that’s where I learned what the B-screw really does!

I noticed that the derailleur guide pulley is pretty close to the big cogs (where it shifts inward well/(nearly too-)quickly), and pretty far away on the smaller cogs (where it shifts inward poorly/slowly). So for fun I turned the B-screw to bring the guide pulley closer to the cogs, even though it made it too close to the largest cog to shift into it. And, lo and behold, the #7->#6 shift got much snappier!

This explains why the 2-cog jumping was greatly reduced when I switched from an 11-36t cassette to an 11-34t cassette as described in my original post. It’s not actually anything to do with the big 36t cog being able to better “grab” the chain when it shouldn’t. It’s because the smaller 34t cassette allowed me to set the B-screw looser, essentially “raising” the height of the guide pulley. That adjustment means that the guide pulley is then closer to ALL the cogs on the cassette than it is when it needs to be set further away to accommodate the bigger 36t cog. That in turn means that the #7->#6 shift happens faster (because the chain angle is greater), so that leads naturally (but non-obviously) to a looser setting of cable tension when dialing it in, which is what actually makes the overshift on #2->#1 less-likely.

Then to make sure I wasn’t just imagining things, I reset the B-screw to the as-close-as-possible 5-6mm gap between the guide pulley and the 36t cog, and then measured the gap between the pulley and all the other cogs. The data, from largest cog to smallest cog:

#1 (36t): 6mm

#2 (32t): 11mm

#3 (28t): 15mm

#4 (24t): 19mm

#5 (21t): 23mm

#6 (18t): 25mm

#7 (15t): 27mm

#8 (13t): 24mm

#9 (11t): 22mm

So we see that while the gap steadily increases as the derailleur moves outward, it actually reaches a peak at #7, and then starts shrinking again. And that peak gap is precisely where the slowest shifting occurs!! Eureka!

I’ve read threads here where people debate the value/point of the B-adjustment, but haven’t quite seen its purpose stated as clearly as my experiments revealed to me: its primary purpose is to allow different cassettes to be used with a single derailleur design. While also keeping the guide pulley as close to the entire cog range as possible for each particular cassette, because minimizing that gap increases the chain angle, which makes shifting faster.

It seems that in an ideal system, the derailleur pulley would maintain that minimal 6mm gap from all cogs. Essentially you’d want the “slope” of the derailleur’s inward movement to match the “slope” of the line drawn from the tooth of the cassette’s smallest cog to the tooth of its largest cog.

In this particular case, my measurements show that the slopes are far from matched. But, using a cassette with a smaller largest cog does allow the system to be adjusted closer to that ideal. So while the Shimano specs for both my new and old derailleur show that they’re compatible with cassettes whose largest cog ranges from 32t to 36t, it’s now clear that shifting will be snappier if that largest cog is smaller.

(I’m guessing I probably could have learned all this (and more) much faster from “The Dancing Chain” recommended by Andrew, but I guess struggling through it myself means maybe I’ll remember it more?)

But maybe there is another derailleur whose “slope” would be a better match for my 11-36t cassette? Perhaps I screwed up in getting the RD-M592, which is essentially just a copy of the RD-M772. Maybe the Alivio RD-M4000 operates with a different slope? I don’t suppose anyone has a database of derailleur slopes? (I don’t even know if there’s a term for it, much less if “slope” is the right term, so I’ve had no luck searching for such info).

Or maybe I guessed really wrong in my expensive exploration and should have jumped directly to Microshift’s Advent shifter/derailleur/cassette. Their derailleurs must have a different slope, in order to handle the 11-42t/11-46t cassettes they’re spec'ed for. Especially because I’d then be using the 11-42t cassette, the smaller (presumably best-shifting) end of the Advent spec, unlike the 11-36t Shimano, which is the largest (worst-shifting) end of the Shimano spec. Argh!

I still have a new Microshift thumb shifter coming, to see if the overshift amount is excessive (for Microshift) on the existing shifter. Because I do think some amount of overshifting could improve things over the Shimano zero-overshift style. But, maybe I’ve just gotten too anal, and the current Shimano setup will end up being “good enough”. I just feel like now that I’ve learned some of the principles, it would be nice to have a setup closer to the “ideal” because that would allow larger tolerances in any adjustments and non-ideal conditions.

First, an answer to the title of this thread: Shimano DEFINITELY does much less overshifting than my current Microshift shifter. In fact, it (at least, the cheap Altus SL-M2010 trigger shifter I bought, I haven't tested the Shimano bar-ends) exhibits ZERO overshifting. It’s actually a little freaky to see how the derailleur sticks precisely where it’s pushed to after each click and doesn’t settle back at all. I have no idea if this is standard across the brand (it seems unlikely given the “settling back” of the cable shown in the Park Tool video I posted, which likely used a Shimano shifter), but it at least shows that significant variation exists across the universe of shifters. Here’s video of the Shimano, followed by my original Microshift video so you can see the stark difference:

Due to that lack-of-overshift, it does seem like the Shimano relies a lot more on the “engineered” cogs/chain (as described by Andrew here). So that makes shifting to a larger cog a bit slower than the Microshift, because the wheel has to spin around enough for the chain to find a place to climb up the cog. In contrast, the Microshift’s overshifting just yanks the chain so far that it doesn’t really need any help from the cog surface.

Backing up here’s everything I’ve done/replaced since last time:

- Re-straightened the derailleur hanger. I had previously used the “use a front wheel as an alignment tool, with the QR hub screwed into the derailleur hanger” method. My acquisition of an actual alignment tool revealed that the wheel method must not be particularly accurate (I think because the weight of the wheel bends the hanger during the alignment process). Anyway, that still didn’t change much, if anything.

- New chain; old one was nearing its stretch-limit, so what the heck.

- New cassette: just to eliminate the possibility that the old cassette was somehow contributing to the problem. I got a Microshift 11-36t to replace the Shimano 11-36t, largely because the Microshift has a smaller jump between the last two cogs, 32t->36t vs. 30t->36t. I thought maybe that biggish jump on the Shimano was a source of the problem, but also, figured my wife might prefer having a smaller jump between those gears anyway. Downside is that it weighs 25% more (485g vs. 385g). Oh, and it also didn’t fix anything.

- New rear derailleur: to eliminate the possibility that the derailleur was bent or worn, I replaced the 2007-designed RD-M772 with the 2009-designed RD-M592. They’re basically the same design, and it resulted in no difference, so it seems the RD-M772 was fine. And again, 25% lighter, at 227g vs. the new 283g.

- Replaced cable and housing. This probably had the biggest effect, at least when using the overshifting Microshift shifter, because lowering the resistance of the cable allows the derailleur spring to help the overshift to “settle back” faster, reducing the amount of time that the derailleur is in a position to cause a 2-gear jump. Only after I’d already replaced the housing did I notice that it was probably the cable contributing to most of the excess friction: it seemed one of the strands had somehow slightly unwound, so from the cable-end to half-way up I could feel a slight roughness when running my fingers along it.

And that’s where I learned what the B-screw really does!

I noticed that the derailleur guide pulley is pretty close to the big cogs (where it shifts inward well/(nearly too-)quickly), and pretty far away on the smaller cogs (where it shifts inward poorly/slowly). So for fun I turned the B-screw to bring the guide pulley closer to the cogs, even though it made it too close to the largest cog to shift into it. And, lo and behold, the #7->#6 shift got much snappier!

This explains why the 2-cog jumping was greatly reduced when I switched from an 11-36t cassette to an 11-34t cassette as described in my original post. It’s not actually anything to do with the big 36t cog being able to better “grab” the chain when it shouldn’t. It’s because the smaller 34t cassette allowed me to set the B-screw looser, essentially “raising” the height of the guide pulley. That adjustment means that the guide pulley is then closer to ALL the cogs on the cassette than it is when it needs to be set further away to accommodate the bigger 36t cog. That in turn means that the #7->#6 shift happens faster (because the chain angle is greater), so that leads naturally (but non-obviously) to a looser setting of cable tension when dialing it in, which is what actually makes the overshift on #2->#1 less-likely.

Then to make sure I wasn’t just imagining things, I reset the B-screw to the as-close-as-possible 5-6mm gap between the guide pulley and the 36t cog, and then measured the gap between the pulley and all the other cogs. The data, from largest cog to smallest cog:

#1 (36t): 6mm

#2 (32t): 11mm

#3 (28t): 15mm

#4 (24t): 19mm

#5 (21t): 23mm

#6 (18t): 25mm

#7 (15t): 27mm

#8 (13t): 24mm

#9 (11t): 22mm

So we see that while the gap steadily increases as the derailleur moves outward, it actually reaches a peak at #7, and then starts shrinking again. And that peak gap is precisely where the slowest shifting occurs!! Eureka!

I’ve read threads here where people debate the value/point of the B-adjustment, but haven’t quite seen its purpose stated as clearly as my experiments revealed to me: its primary purpose is to allow different cassettes to be used with a single derailleur design. While also keeping the guide pulley as close to the entire cog range as possible for each particular cassette, because minimizing that gap increases the chain angle, which makes shifting faster.

It seems that in an ideal system, the derailleur pulley would maintain that minimal 6mm gap from all cogs. Essentially you’d want the “slope” of the derailleur’s inward movement to match the “slope” of the line drawn from the tooth of the cassette’s smallest cog to the tooth of its largest cog.

In this particular case, my measurements show that the slopes are far from matched. But, using a cassette with a smaller largest cog does allow the system to be adjusted closer to that ideal. So while the Shimano specs for both my new and old derailleur show that they’re compatible with cassettes whose largest cog ranges from 32t to 36t, it’s now clear that shifting will be snappier if that largest cog is smaller.

(I’m guessing I probably could have learned all this (and more) much faster from “The Dancing Chain” recommended by Andrew, but I guess struggling through it myself means maybe I’ll remember it more?)

But maybe there is another derailleur whose “slope” would be a better match for my 11-36t cassette? Perhaps I screwed up in getting the RD-M592, which is essentially just a copy of the RD-M772. Maybe the Alivio RD-M4000 operates with a different slope? I don’t suppose anyone has a database of derailleur slopes? (I don’t even know if there’s a term for it, much less if “slope” is the right term, so I’ve had no luck searching for such info).

Or maybe I guessed really wrong in my expensive exploration and should have jumped directly to Microshift’s Advent shifter/derailleur/cassette. Their derailleurs must have a different slope, in order to handle the 11-42t/11-46t cassettes they’re spec'ed for. Especially because I’d then be using the 11-42t cassette, the smaller (presumably best-shifting) end of the Advent spec, unlike the 11-36t Shimano, which is the largest (worst-shifting) end of the Shimano spec. Argh!

I still have a new Microshift thumb shifter coming, to see if the overshift amount is excessive (for Microshift) on the existing shifter. Because I do think some amount of overshifting could improve things over the Shimano zero-overshift style. But, maybe I’ve just gotten too anal, and the current Shimano setup will end up being “good enough”. I just feel like now that I’ve learned some of the principles, it would be nice to have a setup closer to the “ideal” because that would allow larger tolerances in any adjustments and non-ideal conditions.

Last edited by Neil G.; 02-19-23 at 05:35 PM.

#18

Junior Member

Thread Starter

Fixed! Finally!

This solution? A different derailleur design. Huge thanks to Andrew R Stewart and especially hokiefyd for their previous threads I found analyzing/discussing Shimano's "Shadow" derailleurs vs. their "Double Servo" derailleurs.

On hokiefyd 's advice, got a Shimano Alivio RD-T4000 "Double Servo" rear derailleur, the design that predates "Shadow". I'm glad to add further data to his belief that Shadow derailleurs sacrificed shifting quality on wide-range cassettes in exchange for (dubious) other benefits. The new (well, old-school!) derailleur works so well that I think I could undo all my other changes (go back to the hugely overshifting Microshift shifters, rough cable, old chain and cassette, and re-bend the derailleur hanger), and the shifting would still be much-improved.

Replying to myself:

It turns out that this "Double Servo" design is EXACTLY what I described here, and just didn't know about yet when I wrote those words. If I would have had the time and patience to make a drawing of this "ideal system" I was describing in my last post, I would have now felt like an idiot because Shimano already made that exact drawing and used it on their branding page for Double Servo!

"SHIMANO’s double servo-panta mechanism enables the rear derailleur to move in an optimum path. The guide pulley tracks the cogs closely while moving front to back, optimizing each shift. Perfect tracking contributes to the most accurate SIS shifting. Keeps rear derailleur guide pulley an optimum distance from each sprocket."

Yup, exactly what I was looking for, and kind of funny/sad that, by implication, Shimano no longer cared about "the most accurate SIS shifting" when changing to their "Shadow" designs.

Once I read this, I had pretty high hopes that this would finally be the solution to my problem, but I still had no idea how big the improvement would be. I thought if I was lucky that 27mm gap between guide pulley and cog #7 would be reduced to like 20mm, which should be enough. Instead, there is no gear where the gap exceeds even 12mm! The gaps are not quite as constant as that idealized drawing, but it's pretty darn close!

Note that the new set of measurements were more of a challenge to obtain, due to the completely different derailleur design. With the Shadows, only the parallelogram has an effect on the guide pulley position, because the derailleur body as a whole is effectively fixed in place. Whereas with the Double Servo, the guide pulley position is determined by both the parallelogram shape and the rotational position of the derailleur body around the B-axis (parallel to the hub). And that rotational position is determined by a dynamic interaction between the B-spring (a spring that doesn't exist in Shadow derailleurs) and the cage spring, the latter of whose tension is determined by the chain pulling on it. The upshot is that the spacing with the Double Servo derailleur needs to be measured with the chain on, which quite gets in the way of measuring the gap! But I think I was able to get them close enough.

But does that dramatic reduction in gap result in real-world improvement? Yes! With the Shadow derailleur, the best shifting performance I could get was "almost-never overshifting from #3->#1 anymore, but slightly-slow shifting from #7->#6". If I increased cable tension by 1/8th of a turn, I would get unacceptably-frequent #3->#1 overshifting, and if I decreased it by 1/8th of a turn, I would get shifts where #7->#6 would never happen, without at additional slight push on the shift lever.

Now, I can rotate the barrel adjuster an entire turn in either direction before I run into shifting as bad as the "best" performance I could get with the Shadow derailleur. That's at least an 8x improvement! Plenty of added tolerance to help weather inevitable cable wear, chain wear, shifter wear, sticky bits, derailleur-hanger alignment, etc. Finally that purported forgiving tolerance of a 9-speed setup that seemed so logical, but I was not seeing!

Despite the marketing, I'm not entirely convinced that the more-complex "Double Servo" derailleur design (3 springs vs. 2 springs, with a complex dynamic system determining pulley position) is actually needed to achieve this minimal pulley-cog gap. It seems to me that the same thing could also be achieved with a Shadow design, if the parallelogram angle/shape was just designed to better match the slope of the cogs. But whatever, I'm just glad I was able to find a derailleur that better matched my cog-slope without having to try out 20 different derailleurs!

Ironically, Kontact 's very first reply on this thread ('The cable housing to the RD is way too short. It should be a big gentle curve extending 4" behind the barrel adjuster.') was inadvertently correct! Turns out all I needed to do was replace the sleek, modern derailleur with one of those old-school derailleurs that require the giant dorky loop! Oh well, small price to pay for such a night-and-day improvement!

Oh well, small price to pay for such a night-and-day improvement!

Oh, and the last bit, I also got a new Microshift thumb shifter (prior to getting the new derailleur), and it shows FAR less overshift than the old Microshift did. In fact, I have to look really closely to see that exhibits any more overshift than the zero overshift of the new Shimano trigger shifter. Of course that still didn't solve the problem, and like I said, I bet the tolerance granted by the new derailleur would handle the old overshifting Microshift just fine. Still not sure why the old shifter is exhibiting such different behavior than the new one (I'm reluctant to take apart the new shifter just to compare!), but one guess is that I could have had the indexing bolt improperly tightened, and maybe that led to premature wear and slop in the mechanism. Or, maybe it was just a dud to begin with. Now that I have a baseline of what "good" Microshift shifting looks like, I'll be able to report back in another 8000 miles to see if it has degraded again!

This solution? A different derailleur design. Huge thanks to Andrew R Stewart and especially hokiefyd for their previous threads I found analyzing/discussing Shimano's "Shadow" derailleurs vs. their "Double Servo" derailleurs.

On hokiefyd 's advice, got a Shimano Alivio RD-T4000 "Double Servo" rear derailleur, the design that predates "Shadow". I'm glad to add further data to his belief that Shadow derailleurs sacrificed shifting quality on wide-range cassettes in exchange for (dubious) other benefits. The new (well, old-school!) derailleur works so well that I think I could undo all my other changes (go back to the hugely overshifting Microshift shifters, rough cable, old chain and cassette, and re-bend the derailleur hanger), and the shifting would still be much-improved.

Replying to myself:

It seems that in an ideal system, the derailleur pulley would maintain that minimal 6mm gap from all cogs. Essentially you’d want the “slope” of the derailleur’s inward movement to match the “slope” of the line drawn from the tooth of the cassette’s smallest cog to the tooth of its largest cog.

But maybe there is another derailleur whose “slope” would be a better match for my 11-36t cassette? Perhaps I screwed up in getting the RD-M592, which is essentially just a copy of the RD-M772. Maybe the Alivio RD-M4000 operates with a different slope? I don’t suppose anyone has a database of derailleur slopes? (I don’t even know if there’s a term for it, much less if “slope” is the right term, so I’ve had no luck searching for such info).

But maybe there is another derailleur whose “slope” would be a better match for my 11-36t cassette? Perhaps I screwed up in getting the RD-M592, which is essentially just a copy of the RD-M772. Maybe the Alivio RD-M4000 operates with a different slope? I don’t suppose anyone has a database of derailleur slopes? (I don’t even know if there’s a term for it, much less if “slope” is the right term, so I’ve had no luck searching for such info).

"SHIMANO’s double servo-panta mechanism enables the rear derailleur to move in an optimum path. The guide pulley tracks the cogs closely while moving front to back, optimizing each shift. Perfect tracking contributes to the most accurate SIS shifting. Keeps rear derailleur guide pulley an optimum distance from each sprocket."

Yup, exactly what I was looking for, and kind of funny/sad that, by implication, Shimano no longer cared about "the most accurate SIS shifting" when changing to their "Shadow" designs.

Once I read this, I had pretty high hopes that this would finally be the solution to my problem, but I still had no idea how big the improvement would be. I thought if I was lucky that 27mm gap between guide pulley and cog #7 would be reduced to like 20mm, which should be enough. Instead, there is no gear where the gap exceeds even 12mm! The gaps are not quite as constant as that idealized drawing, but it's pretty darn close!

Code:

M592 T4000 #1 (36t): 6mm 5mm #2 (32t): 11mm 8mm #3 (28t): 15mm 9mm #4 (24t): 19mm 10mm #5 (21t): 23mm 11mm #6 (18t): 25mm 12mm #7 (15t): 27mm 10mm #8 (13t): 24mm 9mm #9 (11t): 22mm 8mm

But does that dramatic reduction in gap result in real-world improvement? Yes! With the Shadow derailleur, the best shifting performance I could get was "almost-never overshifting from #3->#1 anymore, but slightly-slow shifting from #7->#6". If I increased cable tension by 1/8th of a turn, I would get unacceptably-frequent #3->#1 overshifting, and if I decreased it by 1/8th of a turn, I would get shifts where #7->#6 would never happen, without at additional slight push on the shift lever.

Now, I can rotate the barrel adjuster an entire turn in either direction before I run into shifting as bad as the "best" performance I could get with the Shadow derailleur. That's at least an 8x improvement! Plenty of added tolerance to help weather inevitable cable wear, chain wear, shifter wear, sticky bits, derailleur-hanger alignment, etc. Finally that purported forgiving tolerance of a 9-speed setup that seemed so logical, but I was not seeing!

Despite the marketing, I'm not entirely convinced that the more-complex "Double Servo" derailleur design (3 springs vs. 2 springs, with a complex dynamic system determining pulley position) is actually needed to achieve this minimal pulley-cog gap. It seems to me that the same thing could also be achieved with a Shadow design, if the parallelogram angle/shape was just designed to better match the slope of the cogs. But whatever, I'm just glad I was able to find a derailleur that better matched my cog-slope without having to try out 20 different derailleurs!

Ironically, Kontact 's very first reply on this thread ('The cable housing to the RD is way too short. It should be a big gentle curve extending 4" behind the barrel adjuster.') was inadvertently correct! Turns out all I needed to do was replace the sleek, modern derailleur with one of those old-school derailleurs that require the giant dorky loop!

Oh well, small price to pay for such a night-and-day improvement!

Oh well, small price to pay for such a night-and-day improvement!Oh, and the last bit, I also got a new Microshift thumb shifter (prior to getting the new derailleur), and it shows FAR less overshift than the old Microshift did. In fact, I have to look really closely to see that exhibits any more overshift than the zero overshift of the new Shimano trigger shifter. Of course that still didn't solve the problem, and like I said, I bet the tolerance granted by the new derailleur would handle the old overshifting Microshift just fine. Still not sure why the old shifter is exhibiting such different behavior than the new one (I'm reluctant to take apart the new shifter just to compare!), but one guess is that I could have had the indexing bolt improperly tightened, and maybe that led to premature wear and slop in the mechanism. Or, maybe it was just a dud to begin with. Now that I have a baseline of what "good" Microshift shifting looks like, I'll be able to report back in another 8000 miles to see if it has degraded again!

Likes For Neil G.:

#19

Senior Member

Join Date: Jul 2015

Location: NW Oregon

Posts: 2,975

Bikes: !982 Trek 930R Custom, Diamondback ascent with SERIOUS updates, Fuji Team Pro CF and a '09 Comencal Meta 5.5

Mentioned: 15 Post(s)

Tagged: 1 Thread(s)

Quoted: 1299 Post(s)

Liked 739 Times

in

534 Posts

you had multiple problems teaming up to cause a big Problem... welcome to a mechanic's life. Glad you kept going until you had the bigger Problem solved. I had two similar problems this year.. one was a mis-welded(too far Forward!) Der. hanger on a trike, solved by installing an Alivio "Mega-Range" der. to replace hideous garbage, a far better twist shifter, and a higher quality chain.... the other was solved by installing an Altus "Mega-Range" der. in place of an XT der., "just to test........"

#20

Newbie

Comparing microshift and Shimano, really? Try Shimano and I hope you won't get back to microshift.