Rebuilding Hi-E hubs?

#1

WGB

Thread Starter

Join Date: Jul 2017

Location: Niagara Region

Posts: 2,926

Bikes: Panasonic PT-4500

Mentioned: 46 Post(s)

Tagged: 0 Thread(s)

Quoted: 1804 Post(s)

Liked 2,341 Times

in

1,382 Posts

Rebuilding Hi-E hubs?

I have two Hi-E front hubs with the skewers. Problem is, they desperately need new bearings.

I spoke with the man who distributed them in Canada and he said that if he recalled correctly the wheels had to be unlaced and mailed back to Hi-E Engineering due to the proprietary system for bearing removal. Apparently, you could machine out the lip that held the bearings in and then install a replacement (but what would hold the bearing in the hub after you were done?).

Can they be rebuilt, or will i just have to strip off the rims and tank the hubs? like the quick releases though......

I spoke with the man who distributed them in Canada and he said that if he recalled correctly the wheels had to be unlaced and mailed back to Hi-E Engineering due to the proprietary system for bearing removal. Apparently, you could machine out the lip that held the bearings in and then install a replacement (but what would hold the bearing in the hub after you were done?).

Can they be rebuilt, or will i just have to strip off the rims and tank the hubs? like the quick releases though......

#2

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 2,006

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1188 Post(s)

Liked 2,591 Times

in

1,086 Posts

I have done it but only after the spokes are out. I pulled the flanges off the "can" and then the beairngs come off the axles.

I used the quill on a milling machine. Held one flange in the mill vise, probably in soft jaws custom made to fit the flange (wood? I forget). Made a tool by brazing 4 spokes to a piece of tubing, 3/4" diameter maybe (doesn't matter), that I could hold in a collet in the spindle. The 4 spokes go into 4 holes equally spaced around the flange, and nipples are threaded onto the backside of the flange. Then pull up with the quill. It wasn't a very tight press fit, not too much force required. A drill press would probably work fine, though I didn't try that. Pressing back together with the new bearings can be done in a vice with suitable pusher pieces made of wood or plastic to not dent the soft alloy.

This was 30 years ago, so don't ask me for too much more detail. I still have the tube with the 4 spokes brazed to it, around here somewhere. I'd offer bearing replacement as a service but I'm so slow that it'll probably cost more than the hubs are worth. If I had a bunch to do, I suppose I'd get good at it, but at my current rate of one hub in the 50 years I've been a bike mechanic, that's not enough repetition to develop a muscle memory!

Sadly, Harlan is no longer with us, but there may be someone out there continuing to carry the torch. Anyone know?

Mark B

I used the quill on a milling machine. Held one flange in the mill vise, probably in soft jaws custom made to fit the flange (wood? I forget). Made a tool by brazing 4 spokes to a piece of tubing, 3/4" diameter maybe (doesn't matter), that I could hold in a collet in the spindle. The 4 spokes go into 4 holes equally spaced around the flange, and nipples are threaded onto the backside of the flange. Then pull up with the quill. It wasn't a very tight press fit, not too much force required. A drill press would probably work fine, though I didn't try that. Pressing back together with the new bearings can be done in a vice with suitable pusher pieces made of wood or plastic to not dent the soft alloy.

This was 30 years ago, so don't ask me for too much more detail. I still have the tube with the 4 spokes brazed to it, around here somewhere. I'd offer bearing replacement as a service but I'm so slow that it'll probably cost more than the hubs are worth. If I had a bunch to do, I suppose I'd get good at it, but at my current rate of one hub in the 50 years I've been a bike mechanic, that's not enough repetition to develop a muscle memory!

Sadly, Harlan is no longer with us, but there may be someone out there continuing to carry the torch. Anyone know?

Mark B

Likes For bulgie:

#3

Senior Member

Join Date: Feb 2020

Posts: 2,830

Mentioned: 49 Post(s)

Tagged: 0 Thread(s)

Quoted: 1110 Post(s)

Likes: 0

Liked 1,331 Times

in

786 Posts

Unlace the wheel.

Make two hardwood blocks about 4"x4" with holes just larger than the flange where it joins the hub shell, and thickness just a little less than half the width between the flanges.

Drill a pair of holes at 90 degrees to the hub-hole, so you can hold the things together with a pair of bolts and nuts after you do the next step (do this first to make sure the hole-halves stay aligned).

Cut the blocks so each has a half-circle.

Bolt the blocks around the hub shell, and use wedges to force them apart - some sanded-smooth wood shingles with wax-paper between the surfaces will do.

Make two hardwood blocks about 4"x4" with holes just larger than the flange where it joins the hub shell, and thickness just a little less than half the width between the flanges.

Drill a pair of holes at 90 degrees to the hub-hole, so you can hold the things together with a pair of bolts and nuts after you do the next step (do this first to make sure the hole-halves stay aligned).

Cut the blocks so each has a half-circle.

Bolt the blocks around the hub shell, and use wedges to force them apart - some sanded-smooth wood shingles with wax-paper between the surfaces will do.

#4

Senior Member

Join Date: Jun 2006

Posts: 20,305

Mentioned: 130 Post(s)

Tagged: 0 Thread(s)

Quoted: 3464 Post(s)

Liked 2,831 Times

in

1,997 Posts

Hi-E “quick releases”… just don’t use the ALL aluminum ones.

Likes For repechage:

#5

WGB

Thread Starter

Join Date: Jul 2017

Location: Niagara Region

Posts: 2,926

Bikes: Panasonic PT-4500

Mentioned: 46 Post(s)

Tagged: 0 Thread(s)

Quoted: 1804 Post(s)

Liked 2,341 Times

in

1,382 Posts

It seems there are a lot of hubs out there that are for sale but it seems they must have been stored in a damp place as all advertised with "rough bearings". I got these from a fellow who storEd them for years in a garage. Perhaps the design allowed moisture to get in and if the hubs weren't stored in a dry place the design is susceptible to the bearings seizing?

I'll unlace the wheel as the rims are near mint (IIRC they are 20 spoke count so I certainly would crush them!). The man I spoke to said that he has a few sets and "one of these days" he plans to do exactly what @bulgie did as he says that will work. Again, though it's only worth it if you have a good few to do.

Thank you all.

I'll unlace the wheel as the rims are near mint (IIRC they are 20 spoke count so I certainly would crush them!). The man I spoke to said that he has a few sets and "one of these days" he plans to do exactly what @bulgie did as he says that will work. Again, though it's only worth it if you have a good few to do.

Thank you all.

#6

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,851

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 850 Post(s)

Liked 1,278 Times

in

674 Posts

seems like an awful lot of trouble for that hub.

I don't trust them.

/markp

I don't trust them.

/markp

Likes For mpetry912:

Likes For El Chaba:

#8

only here for the "LIKES"

Join Date: Nov 2004

Location: squirrel cage of anxiety and delusion

Posts: 483

Mentioned: 143 Post(s)

Tagged: 0 Thread(s)

Quoted: 1644 Post(s)

Likes: 0

Liked 2,245 Times

in

1,053 Posts

you might be able to glean some rebuilding info and insight from this thread:

https://www.bikeforums.net/classic-v...esistance.html

also, Hi-E literature mentions that bearings will feel "stiff" at no load.

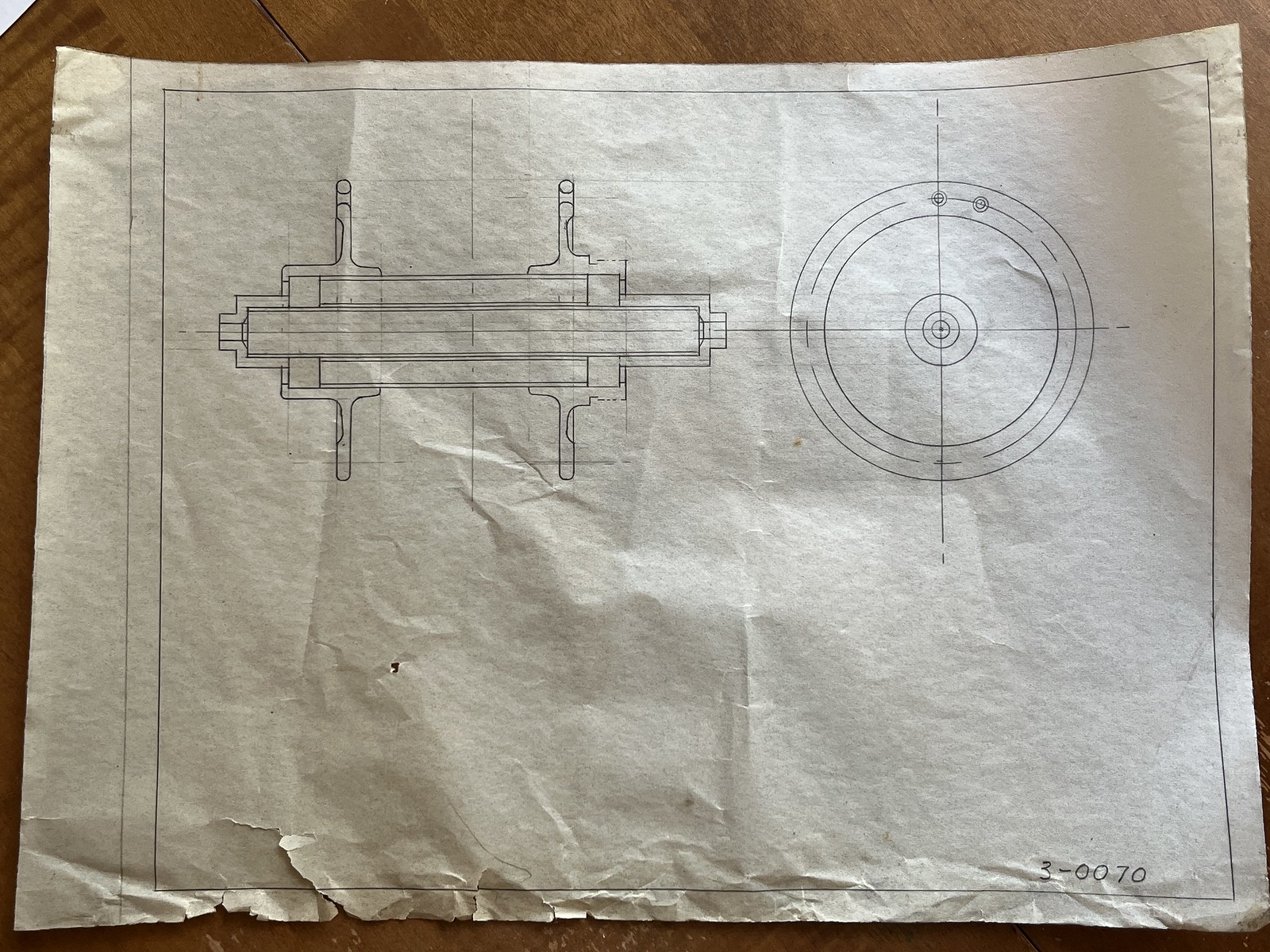

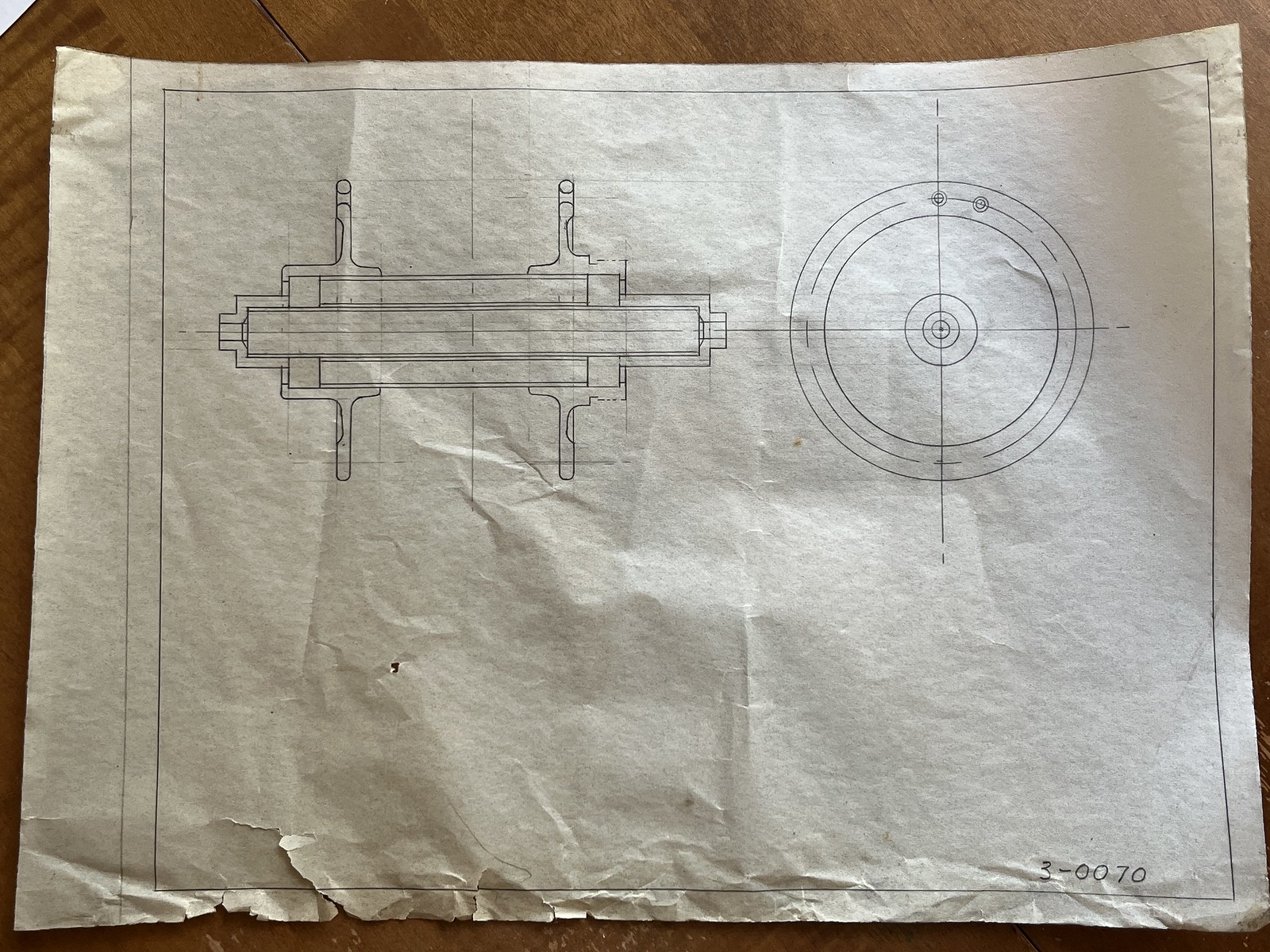

for historical reference, i have what i believe is an original Harlan / Hi-E technical drawing of a Hi-E hub. i got it when i bought a ton of stuff from Jeff Archer's son after Jeff's death.

it was in with other technical drawings (a lot of airplane(?) stuff) that was from Hi-E, and was in a pile on the floor, waiting for the next trash pick up.

https://www.bikeforums.net/classic-v...esistance.html

also, Hi-E literature mentions that bearings will feel "stiff" at no load.

for historical reference, i have what i believe is an original Harlan / Hi-E technical drawing of a Hi-E hub. i got it when i bought a ton of stuff from Jeff Archer's son after Jeff's death.

it was in with other technical drawings (a lot of airplane(?) stuff) that was from Hi-E, and was in a pile on the floor, waiting for the next trash pick up.

Last edited by hazetguy; 08-12-23 at 11:13 AM.

Likes For hazetguy:

#9

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,851

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 850 Post(s)

Liked 1,278 Times

in

674 Posts

yes it sure looks like the flanges are pressed on to the central tube and the flanges must be removed to get access to the bearings

a lot like the high flange hubs made recently by Jim Merz

remember to clock the spoke holes properly when re-assembling

Seems like a lot of trouble

/markp

a lot like the high flange hubs made recently by Jim Merz

remember to clock the spoke holes properly when re-assembling

Seems like a lot of trouble

/markp

#10

Senior Member

Perhaps, set them aside as an historical artifact.

Are the flanges and body both made of aluminum or is the body steel? If the materials differ, heat or cold might allow the press fit to loosen for disassembly.

Are the flanges and body both made of aluminum or is the body steel? If the materials differ, heat or cold might allow the press fit to loosen for disassembly.

Likes For Bad Lag:

#13

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 2,006

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1188 Post(s)

Liked 2,591 Times

in

1,086 Posts

I used them for many eyars, and most if not all my MTB racing was done on them. I am a clydesdale, though I preferred to keep the tires on the dirt, not a lot of BMX-style jumping. A certain amount of drop-offs though. Coming from a Trials background, I wasn't averse to, say, riding off a picnic table or down a flight of stairs.

I did crack one flange on the front, from building the wheel radial (not smart). And it was a tiny flange, with 36 holes, which put the spoke holes very close to each other. I built it with 28 spokes, which probably made it even worse. The cracks formed from one hole to the next, and the wheel never failed, I saw it in time. Harlan replaced the hub for free, with a brand new hub, even though it was my fault. Don't expect that sort of warranty support nowadays though! Just don't build it radial.

The original Cunningham Grease Guard hubs, that he made just for his own bikes (pre-WTB), were made from Hi-E hubs. He took 'em apart and modified them in some ways but structurally they were the same. Cunningham MTBs got ridden as hard as anything out there.

The superlight slow-release with the alloy skewer (not just the ends, even the ~5 mm part was alu) was for road timetrial only, but if you used the steel skewer, I think they were safe as milk.

Mark B

Likes For bulgie:

#14

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 2,006

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1188 Post(s)

Liked 2,591 Times

in

1,086 Posts

I had a brand new Phil that became almost unusable after one horribly wet ride, water got in and rusted the bearings. Another on a tandem where the freewheel just kept threading on, pushing the flange inward until the wheel buckled.

Phil hubs have a reputation for reliability, and they are pretty good, and more easily serviced than a Hi-E, just pointing out they're not invincible. Also when I was a racer and weight-weenie, the weight difference was substantial.

Mark B, Hi-E fan.

Likes For bulgie:

#15

Senior Member

Join Date: Dec 2016

Posts: 590

Mentioned: 12 Post(s)

Tagged: 0 Thread(s)

Quoted: 192 Post(s)

Liked 568 Times

in

198 Posts

Implying they are unsafe? In what way?

I used them for many eyars, and most if not all my MTB racing was done on them. I am a clydesdale, though I preferred to keep the tires on the dirt, not a lot of BMX-style jumping. A certain amount of drop-offs though. Coming from a Trials background, I wasn't averse to, say, riding off a picnic table or down a flight of stairs.

I did crack one flange on the front, from building the wheel radial (not smart). And it was a tiny flange, with 36 holes, which put the spoke holes very close to each other. I built it with 28 spokes, which probably made it even worse. The cracks formed from one hole to the next, and the wheel never failed, I saw it in time. Harlan replaced the hub for free, with a brand new hub, even though it was my fault. Don't expect that sort of warranty support nowadays though! Just don't build it radial.

The original Cunningham Grease Guard hubs, that he made just for his own bikes (pre-WTB), were made from Hi-E hubs. He took 'em apart and modified them in some ways but structurally they were the same. Cunningham MTBs got ridden as hard as anything out there.

The superlight slow-release with the alloy skewer (not just the ends, even the ~5 mm part was alu) was for road timetrial only, but if you used the steel skewer, I think they were safe as milk.

Mark B

I used them for many eyars, and most if not all my MTB racing was done on them. I am a clydesdale, though I preferred to keep the tires on the dirt, not a lot of BMX-style jumping. A certain amount of drop-offs though. Coming from a Trials background, I wasn't averse to, say, riding off a picnic table or down a flight of stairs.

I did crack one flange on the front, from building the wheel radial (not smart). And it was a tiny flange, with 36 holes, which put the spoke holes very close to each other. I built it with 28 spokes, which probably made it even worse. The cracks formed from one hole to the next, and the wheel never failed, I saw it in time. Harlan replaced the hub for free, with a brand new hub, even though it was my fault. Don't expect that sort of warranty support nowadays though! Just don't build it radial.

The original Cunningham Grease Guard hubs, that he made just for his own bikes (pre-WTB), were made from Hi-E hubs. He took 'em apart and modified them in some ways but structurally they were the same. Cunningham MTBs got ridden as hard as anything out there.

The superlight slow-release with the alloy skewer (not just the ends, even the ~5 mm part was alu) was for road timetrial only, but if you used the steel skewer, I think they were safe as milk.

Mark B

#16

Thread derailleur

Join Date: Mar 2004

Location: Glendora, CA

Posts: 656

Bikes: Croll '94 & Cannondale Supersix '15

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 373 Post(s)

Liked 471 Times

in

270 Posts

OK, if you say so. I preferred the Hi-E. "Poor man's" implies they were cheaper than Phil. I don't remember, is that true? Lots of people thought of Hi-E as an upgrade from Campy.

I had a brand new Phil that became almost unusable after one horribly wet ride, water got in and rusted the bearings. Another on a tandem where the freewheel just kept threading on, pushing the flange inward until the wheel buckled.

Phil hubs have a reputation for reliability, and they are pretty good, and more easily serviced than a Hi-E, just pointing out they're not invincible. Also when I was a racer and weight-weenie, the weight difference was substantial.

Mark B, Hi-E fan.

I had a brand new Phil that became almost unusable after one horribly wet ride, water got in and rusted the bearings. Another on a tandem where the freewheel just kept threading on, pushing the flange inward until the wheel buckled.

Phil hubs have a reputation for reliability, and they are pretty good, and more easily serviced than a Hi-E, just pointing out they're not invincible. Also when I was a racer and weight-weenie, the weight difference was substantial.

Mark B, Hi-E fan.

They cost far less than Phils and, if memory serves, less than Campagnolo.

In the 70's, my brother built a time-trialing wheelset, bragging about shedding a few ounces. I still killed him in the TTs!

Honestly, in all my twenty-five years eBaying, I never saw a single Hi-E on there, while frequently coming across Phils.

That must be worth something. lol

#17

Senior Member

Join Date: Jan 2005

Location: Baltimore, MD

Posts: 5,430

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 2512 Post(s)

Liked 2,993 Times

in

1,699 Posts

Phil hubs have been more easily serviced for many years now, but that wasn't the case early on. Our shop sold a lot of Bullseye hubs simply by pointing out that where you had to send the Phil hubs to the company for service (back then), Bullseye hubs required only the use of one small Allen wrench to remove the axle spacers, allowing easy bearing replacement.

#18

Senior Member

Join Date: May 2012

Location: Point Reyes Station, California

Posts: 4,532

Bikes: Indeed!

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1508 Post(s)

Liked 3,484 Times

in

1,134 Posts

Brent

__________________

"I have a tendency to meander sometimes." B.G.

"I have a tendency to meander sometimes." B.G.

#19

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 2,006

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1188 Post(s)

Liked 2,591 Times

in

1,086 Posts

you had to send the Phil hubs to the company for service (back then)

#20

Thread derailleur

Join Date: Mar 2004

Location: Glendora, CA

Posts: 656

Bikes: Croll '94 & Cannondale Supersix '15

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 373 Post(s)

Liked 471 Times

in

270 Posts

Anyway, the Phils likely outnumbered the Hi-E's from the start, accounting for more listings.

#21

Senior Member

Join Date: Jun 2006

Posts: 20,305

Mentioned: 130 Post(s)

Tagged: 0 Thread(s)

Quoted: 3464 Post(s)

Liked 2,831 Times

in

1,997 Posts

OK, if you say so. I preferred the Hi-E. "Poor man's" implies they were cheaper than Phil. I don't remember, is that true? Lots of people thought of Hi-E as an upgrade from Campy.

I had a brand new Phil that became almost unusable after one horribly wet ride, water got in and rusted the bearings. Another on a tandem where the freewheel just kept threading on, pushing the flange inward until the wheel buckled.

Phil hubs have a reputation for reliability, and they are pretty good, and more easily serviced than a Hi-E, just pointing out they're not invincible. Also when I was a racer and weight-weenie, the weight difference was substantial.

Mark B, Hi-E fan.

I had a brand new Phil that became almost unusable after one horribly wet ride, water got in and rusted the bearings. Another on a tandem where the freewheel just kept threading on, pushing the flange inward until the wheel buckled.

Phil hubs have a reputation for reliability, and they are pretty good, and more easily serviced than a Hi-E, just pointing out they're not invincible. Also when I was a racer and weight-weenie, the weight difference was substantial.

Mark B, Hi-E fan.

the rear, unless one had vertical dropouts, too much customization to get them to hold.

later, the “heavy duty” front hub came out, the original was probably under engineered.

they looked cool.

the later freehub was wild in concept. Radial teeth engagement, essentially no slack.

Harlan was on to something with the cranks, but needed a step beyond - outboard bearings and an oversized axle to really be implemented with.

I drafted one up, but did not come up with a way to attach the non drive side crank arm. This was 1976.

Likes For repechage:

#22

Senior Member

Join Date: Jun 2010

Location: Medford MA

Posts: 2,089

Bikes: Ron Cooper touring, 1959 Jack Taylor 650b ladyback touring tandem, Vitus 979, Joe Bell painted Claud Butler Dalesman, Colin Laing curved tube tandem, heavily-Dilberted 1982 Trek 6xx, René Herse tandem

Mentioned: 80 Post(s)

Tagged: 0 Thread(s)

Quoted: 964 Post(s)

Liked 1,451 Times

in

723 Posts

@bulgie I agree with your take!! All four members of the Cambridge Vitus Club are equipped with Hi-E front hubs and they have not given us a lick of trouble in years of use. I built four wheels in four anodized colors for our équipe, to match our anodized frames. These are technically their MTB hub, with the 10mm axle, so I had to machine the axles down to 9mm to fit our Vitus forks. Bearings were a little rough when I bought the lot off Ebay (from someone down in Harlan's neck of the woods) but before trying to machine something to take the hub apart, I dripped some oil in them and they are fine for our purposes (mock vintage club rides). I do not see how Hi-E are more dangerous than Phils or even Shimano or Campy or Maxicars. I think the most critical thing about the Hi-E is to not squeeze it too tight with the quick release. This can compress the axle enough that the inner races of the bearings will be out of alignment with the outers. This is most common with internal cam quick releases, which exert more force than the lighter weight external cam type. I mostly use internal cam, but if I'm using a Hi-E hub, I want the lightest setup possible. This axle compression occurs on standard cup and cone hubs as well, which is why we adjust them a little loose to compensate.

Honestly, Maxicars are pretty finicky too. I had to build a special expanding tool to remove the bearing outer race from a Maxicar hubshell. It was a big pain and now a guy in Texas is going to send me a whole set to do.

Honestly, Maxicars are pretty finicky too. I had to build a special expanding tool to remove the bearing outer race from a Maxicar hubshell. It was a big pain and now a guy in Texas is going to send me a whole set to do.

__________________

Owner & co-founder, Cycles René Hubris. Unfortunately attaching questionable braze-ons to perfectly good frames since about 2015. With style.

Owner & co-founder, Cycles René Hubris. Unfortunately attaching questionable braze-ons to perfectly good frames since about 2015. With style.

Likes For scarlson:

#23

Senior Member

Join Date: Feb 2008

Location: Peoria, IL

Posts: 4,485

Mentioned: 86 Post(s)

Tagged: 0 Thread(s)

Quoted: 1833 Post(s)

Liked 3,404 Times

in

1,589 Posts

Since we are discussing Hi-E hub repair, may I derail the thread a bit to discuss repair of the QR?

Specifically, I've had two of them where the little pin fell out of the aluminum nut.

On the first one, the pin was not recovered. The second one was nice enough to fall in a place where I could see it!

As with some of Harlan's design, this was very minimal and perhaps not designed for long term use.

The pin is 4.72mm diameter, and the hole in the aluminum nut is only 4.2mm deep, so any leverage on the pin is going to deform the aluminum and allow the pin to loosen in the hole.

FWIW, I've had the first skewer since the 70's and never applied much force to the pin. It lasted until a few years ago. The second one must have gotten more use before I bought it.

It looks like Harlan was improvising an interference fit by "knurling" the pin with 3 depressions along the length. To a casual observer, it looks like someone just smacked it with a chisel.

My repair has been to just apply a bit of JB Weld to the pin and the interior of the hole, and then press them back together with a bench vise.

I'm hoping that the epoxy will fill the gaps, thereby reducing the localized pressure and reducing the tendency of the aluminum to be displaced.

I'm also hoping that the fillet of epoxy will help spread the forces a bit, or at least should crack and break off prior to the pin getting loose, providing a bit of warning before the pin falls out.

(fingers crossed)

I've been around industrial adhesives enough to know that JB Weld is not the ultimate. My guess is that Loc-tite makes some sort of adhesive that is stronger than either the pin or the aluminum nut, and will keep the two bonded together.

Anyone have enough experience to know what adhesive is the right one??

background info:

The pin is 4.72mm OD and 26.2mm long.

The hole is 4.74mm ID and 4.21mm deep.

Since Harlan built these, I'm assuming that the stock and tools used imperial measurements. 4.72mm is pretty much the same as 3/16".

Steve in Peoria

Specifically, I've had two of them where the little pin fell out of the aluminum nut.

On the first one, the pin was not recovered. The second one was nice enough to fall in a place where I could see it!

As with some of Harlan's design, this was very minimal and perhaps not designed for long term use.

The pin is 4.72mm diameter, and the hole in the aluminum nut is only 4.2mm deep, so any leverage on the pin is going to deform the aluminum and allow the pin to loosen in the hole.

FWIW, I've had the first skewer since the 70's and never applied much force to the pin. It lasted until a few years ago. The second one must have gotten more use before I bought it.

It looks like Harlan was improvising an interference fit by "knurling" the pin with 3 depressions along the length. To a casual observer, it looks like someone just smacked it with a chisel.

My repair has been to just apply a bit of JB Weld to the pin and the interior of the hole, and then press them back together with a bench vise.

I'm hoping that the epoxy will fill the gaps, thereby reducing the localized pressure and reducing the tendency of the aluminum to be displaced.

I'm also hoping that the fillet of epoxy will help spread the forces a bit, or at least should crack and break off prior to the pin getting loose, providing a bit of warning before the pin falls out.

(fingers crossed)

I've been around industrial adhesives enough to know that JB Weld is not the ultimate. My guess is that Loc-tite makes some sort of adhesive that is stronger than either the pin or the aluminum nut, and will keep the two bonded together.

Anyone have enough experience to know what adhesive is the right one??

background info:

The pin is 4.72mm OD and 26.2mm long.

The hole is 4.74mm ID and 4.21mm deep.

Since Harlan built these, I'm assuming that the stock and tools used imperial measurements. 4.72mm is pretty much the same as 3/16".

Steve in Peoria

Likes For steelbikeguy:

#24

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 2,006

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1188 Post(s)

Liked 2,591 Times

in

1,086 Posts

I've been around industrial adhesives enough to know that JB Weld is not the ultimate. My guess is that Loc-tite makes some sort of adhesive that is stronger than either the pin or the aluminum nut, and will keep the two bonded together.

Anyone have enough experience to know what adhesive is the right one??

Anyone have enough experience to know what adhesive is the right one??

603 is commonly mentioned as an all-purpose strong adhesive by machinists. I was a machine operator (not a trained machinist) for over 20 years but most of what I know now, I learned in the college of YouTube.

So take what I say with a grain of salt.

So take what I say with a grain of salt.Toughened epoxy like JB Weld is pretty strong too though. I wouldn't wager much on a guess as to which one is stronger.

Loctite 603 can be loosened with heat, if you ever need to. JB Weld would probably have to be machined out if you ever want it apart.

That's all I think I know (I think)!

Mark B

#25

Senior Member

Join Date: Jan 2005

Location: Baltimore, MD

Posts: 5,430

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 2512 Post(s)

Liked 2,993 Times

in

1,699 Posts

Loctite has a dizzying array of formulas and I don't claim to know which is right for this app, but I've found 603 to be amazingly strong. It's green, a bit goopy (not runny), fills gaps OK.

603 is commonly mentioned as an all-purpose strong adhesive by machinists. I was a machine operator (not a trained machinist) for over 20 years but most of what I know now, I learned in the college of YouTube. So take what I say with a grain of salt.

So take what I say with a grain of salt.

Toughened epoxy like JB Weld is pretty strong too though. I wouldn't wager much on a guess as to which one is stronger.

Loctite 603 can be loosened with heat, if you ever need to. JB Weld would probably have to be machined out if you ever want it apart.

That's all I think I know (I think)!

Mark B

603 is commonly mentioned as an all-purpose strong adhesive by machinists. I was a machine operator (not a trained machinist) for over 20 years but most of what I know now, I learned in the college of YouTube.

So take what I say with a grain of salt.

So take what I say with a grain of salt.Toughened epoxy like JB Weld is pretty strong too though. I wouldn't wager much on a guess as to which one is stronger.

Loctite 603 can be loosened with heat, if you ever need to. JB Weld would probably have to be machined out if you ever want it apart.

That's all I think I know (I think)!

Mark B