Corrosion on magnesium lowers replace?

#1

Senior Member

Thread Starter

Join Date: Aug 2006

Posts: 120

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 3 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Corrosion on magnesium lowers replace?

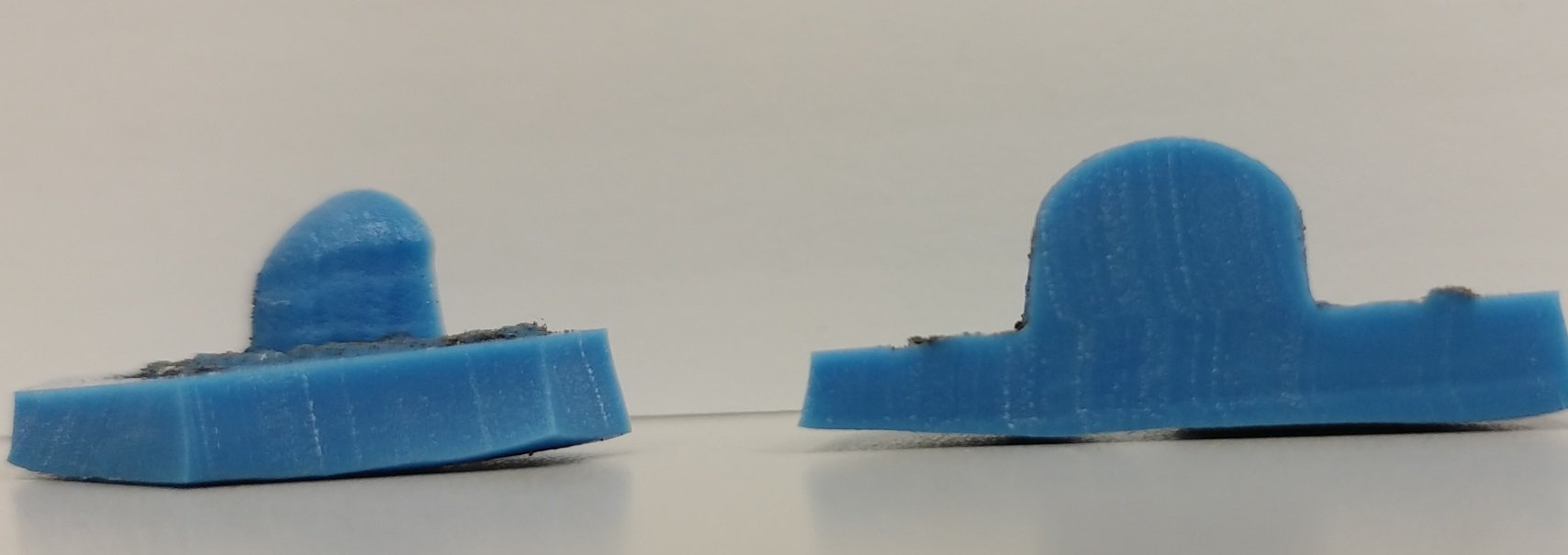

Two seasons of urban winter riding & the road salts seem to have eaten away (pitting?) some of the material surrounding the axle nut/dropout probably from accumulating there. This is a Rockshox Paragon Gold 700c fork with magnesium lowers. Does this warrant a replacement?

Corrosion Magnesium dropout

Corrosion Magnesium dropout

#2

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

I think that this is a case of physical wear plus corrosion. The QR removed the paint, exposing the Mg. The Mg oxidized in a thin layer. The QR then broke through that layer exposing raw Mg, which corroded.

There is a ridge right at the axle slot, where the serrated QR face does not clamp down. One danger I see is that ridge being so high relative to the worn groove that your QR won't clamp effectively. If you determine that the fork is sound in this state, you may wish to carefully file down that ridge if it interferes with the QR clamping.

These things should be designed with some safety factor. Don't know you deep the groove is, or what you use your bike for. If it's just city riding, I'd be tempted to say you're probably ok for now.

Key point: while Mg does oxidize pretty readily (some early slide rules were Mg, and they've corroded badly over the past 70 years), this is not just corrosion. It's a combo of corrosion and wear.

There is a ridge right at the axle slot, where the serrated QR face does not clamp down. One danger I see is that ridge being so high relative to the worn groove that your QR won't clamp effectively. If you determine that the fork is sound in this state, you may wish to carefully file down that ridge if it interferes with the QR clamping.

These things should be designed with some safety factor. Don't know you deep the groove is, or what you use your bike for. If it's just city riding, I'd be tempted to say you're probably ok for now.

Key point: while Mg does oxidize pretty readily (some early slide rules were Mg, and they've corroded badly over the past 70 years), this is not just corrosion. It's a combo of corrosion and wear.

#3

Senior Member

Join Date: Jul 2014

Location: socal

Posts: 4,266

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 883 Post(s)

Liked 824 Times

in

623 Posts

As above, if you can "smooth it down without removing much material, paint it and it's probably OK. Main consideration though is that a front failure could be catastrophic.

#4

Senior Member

Thread Starter

Join Date: Aug 2006

Posts: 120

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 3 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

#6

Senior Member

Thread Starter

Join Date: Aug 2006

Posts: 120

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 3 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

It's my commuter bike 32 miles a day 5 days a week year round in the Chicagoland area. There was some wear on the stanchions too under the seals, but it appears only cosmetic. So I'd like to see if I can get away with only replacing the lowers.

#7

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

Yes, I agree. Pay no attention to what I wrote: you got what I meant. The nice thing, with that duty cycle, is that you're getting your money's worth!

#8

Banned

Theoretically , I have not done this and proven it 1st hand , for you but machine practices suggest

you could machine that face down and create an inlay of stainless steel and make a more durable face

to clamp the axle lock nut against , than the low density, light but soft metal that is Magnesium. ..

....

you could machine that face down and create an inlay of stainless steel and make a more durable face

to clamp the axle lock nut against , than the low density, light but soft metal that is Magnesium. ..

....

#9

Senior Member

Join Date: Dec 2016

Location: Long Island, NY

Posts: 2,112

Bikes: Trek 800 x 2, Schwinn Heavy Duti, Schwinn Traveler, Schwinn Le Tour Luxe, Schwinn Continental, Cannondale M400 and Lambert, Schwinn Super Sport

Mentioned: 14 Post(s)

Tagged: 0 Thread(s)

Quoted: 811 Post(s)

Liked 1,024 Times

in

666 Posts

Theoretically , I have not done this and proven it 1st hand , for you but machine practices suggest

you could machine that face down and create an inlay of stainless steel and make a more durable face

to clamp the axle lock nut against , than the low density, light but soft metal that is Magnesium. ..

....

you could machine that face down and create an inlay of stainless steel and make a more durable face

to clamp the axle lock nut against , than the low density, light but soft metal that is Magnesium. ..

....

#10

Banned

a bit of ingenuity and dremel tool? ...

things seem more difficult to achieve in a post industrial US because you saw no one doing that around you..

no shop or are classes left in schools..

the fork is imported from where they still make things, ... for less..

things seem more difficult to achieve in a post industrial US because you saw no one doing that around you..

no shop or are classes left in schools..

the fork is imported from where they still make things, ... for less..

#11

Senior Member

Join Date: Nov 2014

Location: Eugene, Oregon, USA

Posts: 27,547

Mentioned: 217 Post(s)

Tagged: 0 Thread(s)

Quoted: 18379 Post(s)

Liked 4,512 Times

in

3,354 Posts

It looks like the photo is just the inside surface, rather than the outside surface.

What does the outside surface look like?

Is this a hiigh-speed E-Bike using disc brakes?

I'd probably move to a basic aluminum fork with a Thru-Axle configuration.

One could try a lock nut with less aggressive knurling, but then there is risk of wheel loss which is far more severe.

Assuming adequate material, it should be easy enough to machine out. Just punch it down with the right size of end mill.

Inside part of the fork?? So getting between the fork blades would be a bit of a problem. Would an epoxy joint be adequate?

If designed from the factory, perhaps a hollow sleeve dropout like Colnago has done on some of their Carbon Fiber forks.

What does the outside surface look like?

Is this a hiigh-speed E-Bike using disc brakes?

I'd probably move to a basic aluminum fork with a Thru-Axle configuration.

One could try a lock nut with less aggressive knurling, but then there is risk of wheel loss which is far more severe.

Yea, magnesium is soft stuff. I think the idea of a machined insert for the fork end is a good idea. Who is going to engineer this and machine it? This is how the fork should have been made, in my opinion in the first place. Of course, it wasn't done because the cost would have been too high.

Inside part of the fork?? So getting between the fork blades would be a bit of a problem. Would an epoxy joint be adequate?

If designed from the factory, perhaps a hollow sleeve dropout like Colnago has done on some of their Carbon Fiber forks.

#12

Senior Member

Thread Starter

Join Date: Aug 2006

Posts: 120

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 3 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

I was thinking the same thing with having a steel insert on the inside. And I actually work in a machine shop albeit in the quality side. Have some ideas on how it could be done, but I'm hesitant to go against design intent on the fork. Easier would be to turn down the wheel nuts & add some spacers. I'm not really sure how necessary the knurl on the inside is myself. Hard to see a situation where the wheel slips out if tightened properly.

And the outside faces are fine even have paint still. In good conditions I can maintain 27-29 mph through the 16 mile commute & Chicago streets suck so a suspension fork is necessary.

And the outside faces are fine even have paint still. In good conditions I can maintain 27-29 mph through the 16 mile commute & Chicago streets suck so a suspension fork is necessary.