Broken spokes...

#76

Senior Member

Join Date: Apr 2011

Posts: 7,077

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4416 Post(s)

Liked 1,569 Times

in

1,031 Posts

#77

Senior Member

Join Date: Apr 2011

Posts: 7,077

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4416 Post(s)

Liked 1,569 Times

in

1,031 Posts

The problem I have with the ±20% recommendation is that you can get that kind of variance without using a tool on it. Why spend the money on the tool then? The tool will let you get closer than ±20% so why not use it to do so?

The other problem I have with that recommendation goes back to “all you need is tension” idea. Everyone assumes that the wheel build is bad and that the tension is uneven when spokes break. They never consider that the problem might be with the spokes themselves. My wheels have always been tight and even but even with double butted spokes, breakage was an issue. Going to a spoke with a heavier head stopped the breakage issue. I didn’t change the way I build wheels…they are all built tight and even. The only thing that changed was the spoke. For light riders, they may never break a spoke even on, admittedly, commonly badly build OEM wheels. Heavy riders will likely even break spokes on well built wheels.

Triple butted spokes fix the problem and prevent future problems. I have never been able to understand the resistance to this idea for heavier riders or heavily loaded bicycles.

The other problem I have with that recommendation goes back to “all you need is tension” idea. Everyone assumes that the wheel build is bad and that the tension is uneven when spokes break. They never consider that the problem might be with the spokes themselves. My wheels have always been tight and even but even with double butted spokes, breakage was an issue. Going to a spoke with a heavier head stopped the breakage issue. I didn’t change the way I build wheels…they are all built tight and even. The only thing that changed was the spoke. For light riders, they may never break a spoke even on, admittedly, commonly badly build OEM wheels. Heavy riders will likely even break spokes on well built wheels.

Triple butted spokes fix the problem and prevent future problems. I have never been able to understand the resistance to this idea for heavier riders or heavily loaded bicycles.

"No one considers that they are the problem, not the spokes."

Last edited by Kontact; 11-03-23 at 06:45 PM.

#78

Senior Member

Join Date: Apr 2011

Posts: 7,077

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4416 Post(s)

Liked 1,569 Times

in

1,031 Posts

I understand. When aligning a radio, a lot of us "old timers" can do it by ear and I can get it pretty close. But since I do actually own a signal generator and oscilloscope, I don't have to do it by ear. I bet we can think of a lot of examples where "back in my day, we didn't need no stinkin' ____" (fill in the blank).

If I walk into a shop and their wheel guy says he doesn't own a tensiometer and just does it by ear or by feel, I'm not leaving my wheels with him.

If I walk into a shop and their wheel guy says he doesn't own a tensiometer and just does it by ear or by feel, I'm not leaving my wheels with him.

So if the correct tension is a large range depending on rim and drilling, and then you have a tool that has a large range because of accuracy issues - what is it you think someone who builds wheels with the same kind of spokes all the time are accomplishing by using a meter that gives you less information than what you can feel and hear?

The main reason I use a tensiometer is because I don't have an innate sense for some bladed spokes and undersized spokes like Revolutions, while I can build a Competition wheel literally blindfolded and have the straightness and tension better than what you can do with the best truing stand and tensiometer. If you can tune a guitar, you can get tension even.

What is maybe missing in this discussion is that there doesn't need to be an ideal spoke tension. Having it in the right range, but very even, does a lot more than hitting an imaginary benchmark that was derived without direct reference to cross pattern, flange height or rim rigidity.

Likes For Kontact:

#79

Senior Member

Join Date: Jul 2014

Posts: 1,490

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 1084 Post(s)

Liked 687 Times

in

441 Posts

If a wheelbuilder tells me they don't use a tensiometer, it's like a mechanic telling me they don't ever use a torque wrench and go just by feel. They wouldn't get my business either.

#80

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,728

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,593 Times

in

1,437 Posts

Agreed. IME simply listening while spinning a wheel against your thumbnail will show tension differences smaller than the repeatability error of most tension gauged.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

#81

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,728

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,593 Times

in

1,437 Posts

If someone with a solid record of good workmanship told his secret was having his work blessed by the Pope, I'd say, "OK, I'll wait until you get back from Rome".

Likes For FBinNY:

#82

Senior Member

Join Date: Apr 2011

Posts: 7,077

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4416 Post(s)

Liked 1,569 Times

in

1,031 Posts

I can definitely understand and respect that. Sure, an experienced builder will get it pretty close without actually measuring tension, going simply by feel or by ear. I think they all do. It's that final QC that I'm talking about.

If a wheelbuilder tells me they don't use a tensiometer, it's like a mechanic telling me they don't ever use a torque wrench and go just by feel. They wouldn't get my business either.

If a wheelbuilder tells me they don't use a tensiometer, it's like a mechanic telling me they don't ever use a torque wrench and go just by feel. They wouldn't get my business either.

If getting a handlebar straight in a stem involved adjusting the bolt tension on the face plate, the stem wouldn't say "do not exceed 5nm".

#83

Mostly harmless ™

Join Date: Nov 2010

Location: Novi Sad

Posts: 4,430

Bikes: Heavy, with friction shifters

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 1107 Post(s)

Liked 216 Times

in

130 Posts

I can definitely understand and respect that. Sure, an experienced builder will get it pretty close without actually measuring tension, going simply by feel or by ear. I think they all do. It's that final QC that I'm talking about.

If a wheelbuilder tells me they don't use a tensiometer, it's like a mechanic telling me they don't ever use a torque wrench and go just by feel. They wouldn't get my business either.

If a wheelbuilder tells me they don't use a tensiometer, it's like a mechanic telling me they don't ever use a torque wrench and go just by feel. They wouldn't get my business either.

Went by feel, comparing it to the good wheels that I could see and hold.

When I got the tension meter, I was curious too check the tension - it was pretty good on the wheels I could test that I had built without a tension meter.

Plucking the spokes to check uniform tension and "feel" was all I had used on those wheels.

Similar goes for torque wrenches, at least in my opinion and experience. Even today, I use them only when working on other people's bikes.

Here, at 21:25, is what I think about whether a torque wrench is really needed:

Relja GoldenTouch Novović

#84

Senior Member

Join Date: Jul 2014

Posts: 1,490

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 1084 Post(s)

Liked 687 Times

in

441 Posts

There's the key difference. You focus on ownership of tools, I focus on skill and experience, and judge based on results.

If someone with a solid record of good workmanship told his secret was having his work blessed by the Pope, I'd say, "OK, I'll wait until you get back from Rome".

If someone with a solid record of good workmanship told his secret was having his work blessed by the Pope, I'd say, "OK, I'll wait until you get back from Rome".

I used the example of aligning a radio, or setting bias on an amplifier. Yes, I may do it by ear first to get it within range, and sometimes when I connect a signal generator and oscilloscope I find that I nailed it. Usually though, minor improvements are still possible when you actually measure. Or aligning a cartridge within a turntable headshell. I can get it pretty close by eyeball, but afterwards I'm still going to get out the protractor. There's satisfaction in knowing that the results are as good as is possible, not just subjectively good enough. I should note that there is the phrase "Close enough for Rock and Roll", but that's usually said tongue-in-cheek.

If you need your work blessed by the Pope, I'm out. Superstition is even more subjective than going by "feel" or by human hearing. Unless of course the Pope has a tensiometer and he's the one that's going to measure for you.

Last edited by Jeff Neese; 11-04-23 at 06:34 AM.

#85

Senior Member

Join Date: Jul 2014

Posts: 1,490

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 1084 Post(s)

Liked 687 Times

in

441 Posts

I can inflate my tires and come pretty close to what I want, just by squeezing the tire. In fact, I don't even carry a pressure gauge or have a frame pump with one built in. On the road, I go by feel. But of course when I get home I always get out the pressure gauge and actually measure.

#86

Mostly harmless ™

Join Date: Nov 2010

Location: Novi Sad

Posts: 4,430

Bikes: Heavy, with friction shifters

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 1107 Post(s)

Liked 216 Times

in

130 Posts

That's key. If someone wants to build their own wheels entirely by feel or by plucking, go for it. But if it's someone else's wheels (and especially if you're charging for that service) and the tool to objectively measure the results is available, why wouldn't you? It's simply a matter of being as thorough as possible.

I can inflate my tires and come pretty close to what I want, just by squeezing the tire. In fact, I don't even carry a pressure gauge or have a frame pump with one built in. On the road, I go by feel. But of course when I get home I always get out the pressure gauge and actually measure.

I can inflate my tires and come pretty close to what I want, just by squeezing the tire. In fact, I don't even carry a pressure gauge or have a frame pump with one built in. On the road, I go by feel. But of course when I get home I always get out the pressure gauge and actually measure.

In my city (Novi Sad), there are a lot of bikes, cyclists, and bike shops.

I don't know a single shop that has a spoke tension meter. Why? How?

People here are poor, they can't pay a decent price for the service, and shops must work very fast, very cheaply, or go out of business.

The quality is far from very good, but it gets the job done, bikes get back on the road.

I'd also argue that, with enough practice and experience, you can build good wheels without a tension meter, and there are probably builders who work faster and easier without one (using just a pluck or similar methods).

Relja

Likes For Bike Gremlin:

#87

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,369

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6222 Post(s)

Liked 4,222 Times

in

2,368 Posts

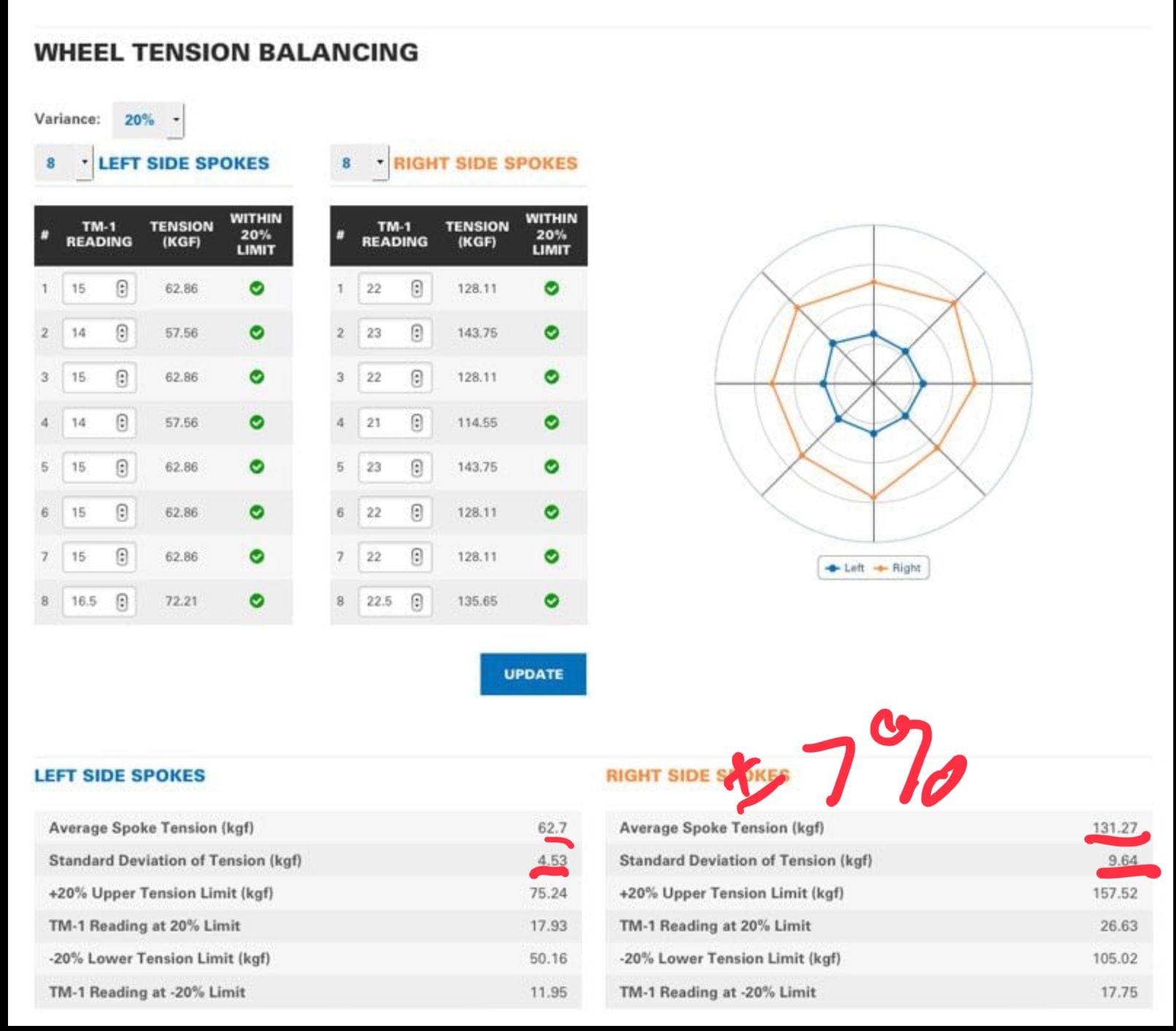

I was reviewing this chart and discovered that it isn’t that clear. It does show the ±20% values but the values for the actual error is far lower. None of the measurements on the chart even approach that ±20%. Dividing the standard deviation by the mean, the value in this 7%. They could stand a lesson in significant figures, however. 17.93 and 23.63 reading on the tension meter? Really? The Park tension meter would be questionable past whole number values.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#88

Senior Member

Join Date: Jul 2014

Posts: 1,490

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 1084 Post(s)

Liked 687 Times

in

441 Posts

I was reviewing this chart and discovered that it isn’t that clear. It does show the ±20% values but the values for the actual error is far lower. None of the measurements on the chart even approach that ±20%. Dividing the standard deviation by the mean, the value in this 7%. They could stand a lesson in significant figures, however. 17.93 and 23.63 reading on the tension meter? Really? The Park tension meter would be questionable past whole number values.

You're probably right that the Park Tool is not accurate out to two decimal places.

#89

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,369

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6222 Post(s)

Liked 4,222 Times

in

2,368 Posts

You're probably right that the Park Tool is not accurate out to two decimal places.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#90

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,728

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,593 Times

in

1,437 Posts

Reading the posts here about the need for using tensiometers to achieve even tension reminds me of the joke about the Kenyan on a bus in Brooklyn.

Short version --- he's on the bus, banging two sticks together. Asked why he says it keeps the lions away. Told there's no lions there, he replies, "see, it works".

IIRC using tension meters this way started with the Barnett Bike School, and the only result is that it's sold countless tensionmeters, and we can have pointless arguments about which is best. (does pine or oak to deter lions better?).

It's a nice long way to solve non-existant problem easily managed reliably and quickly other ways.

Sadly, there are also arguments raised placing tools over skill. FWIW, a skilled craftsman will turn out good work despite not having every conceivable tool. OTOH, use of fancy tools won't magically guaranty good outcomes.

Short version --- he's on the bus, banging two sticks together. Asked why he says it keeps the lions away. Told there's no lions there, he replies, "see, it works".

IIRC using tension meters this way started with the Barnett Bike School, and the only result is that it's sold countless tensionmeters, and we can have pointless arguments about which is best. (does pine or oak to deter lions better?).

It's a nice long way to solve non-existant problem easily managed reliably and quickly other ways.

Sadly, there are also arguments raised placing tools over skill. FWIW, a skilled craftsman will turn out good work despite not having every conceivable tool. OTOH, use of fancy tools won't magically guaranty good outcomes.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

Likes For FBinNY:

#91

Senior Member

Join Date: May 2010

Location: Bastrop Texas

Posts: 4,486

Bikes: Univega, Peu P6, Peu PR-10, Ted Williams, Peu UO-8, Peu UO-18 Mixte, Peu Dolomites

Mentioned: 13 Post(s)

Tagged: 0 Thread(s)

Quoted: 969 Post(s)

Liked 1,632 Times

in

1,048 Posts

If you cannot get Bikesdirect to replace your wheel then just rebuild the one you have. I use Machine Built wheel sets so when I get them I just loosen everything up and then True & Tune the wheel. I have learned to do this the hard way. But, its not that hard. Having someone else rebuild a wheel can be expensive. 100 USD plus. You can do it yourself.

6.00 - Spoke Wrench

20.00 - Spoke Tension Meter

0.00 - Card Board Dish Tool: https://www.roadbikereview.com/threa...for-ya.355398/

18.00 - 20 New Sapim J bend 14ga Spokes: https://www.bikehubstore.com/category-s/350.htm

Youtubes Abound on the process.

Also, if Bikesdirect does send you a new wheel and lets you keep the old one great. Rebuild it and have a spare! What else do you have to do on the soon to come cold Jersey evening then to bring your wheel in ta the kitchen and give it a build. Fun, Fun, FUN...

6.00 - Spoke Wrench

20.00 - Spoke Tension Meter

0.00 - Card Board Dish Tool: https://www.roadbikereview.com/threa...for-ya.355398/

18.00 - 20 New Sapim J bend 14ga Spokes: https://www.bikehubstore.com/category-s/350.htm

Youtubes Abound on the process.

Also, if Bikesdirect does send you a new wheel and lets you keep the old one great. Rebuild it and have a spare! What else do you have to do on the soon to come cold Jersey evening then to bring your wheel in ta the kitchen and give it a build. Fun, Fun, FUN...

__________________

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

#92

Senior Member

Join Date: Apr 2011

Posts: 7,077

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4416 Post(s)

Liked 1,569 Times

in

1,031 Posts

That's key. If someone wants to build their own wheels entirely by feel or by plucking, go for it. But if it's someone else's wheels (and especially if you're charging for that service) and the tool to objectively measure the results is available, why wouldn't you? It's simply a matter of being as thorough as possible.

I can inflate my tires and come pretty close to what I want, just by squeezing the tire. In fact, I don't even carry a pressure gauge or have a frame pump with one built in. On the road, I go by feel. But of course when I get home I always get out the pressure gauge and actually measure.

I can inflate my tires and come pretty close to what I want, just by squeezing the tire. In fact, I don't even carry a pressure gauge or have a frame pump with one built in. On the road, I go by feel. But of course when I get home I always get out the pressure gauge and actually measure.

What is it that a tensiometer is going to tell you that F sharp is not, if you have already established the F sharp is in range and a much more accurate description of relative tension than slider arrow on the crude tensiometer?

#93

Mostly harmless ™

Join Date: Nov 2010

Location: Novi Sad

Posts: 4,430

Bikes: Heavy, with friction shifters

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 1107 Post(s)

Liked 216 Times

in

130 Posts

You seem to be aware that a tensiometer is much less accurate than going by tone, yet you persist in claiming that double checking with a tensiometer produces some sort of superior result.

What is it that a tensiometer is going to tell you that F sharp is not, if you have already established the F sharp is in range and a much more accurate description of relative tension than slider arrow on the crude tensiometer?

What is it that a tensiometer is going to tell you that F sharp is not, if you have already established the F sharp is in range and a much more accurate description of relative tension than slider arrow on the crude tensiometer?

To answer the question:

Tensiometer can tell you the absolute spoke tension

(while plucking the spokes basically tells you only their relative tensions between each other).

For a novice builder, I suppose that knowing the absolute tension can help prevent building wheels that are under or over-tensioned (even if the tension is uniform).

Yes, I suppose you could calculate the absolute tension based on the spoke length, thickness, material, and measuring frequency, but I think using a tensiometer is simpler.

A solution to that problem, without using a tensiometer (and with the relatively thin bicycle spokes), is to rely on hand feel - and check what a wheel that you know is well-tensioned feels like (its spokes that is).

This has worked well for me in practice, so I would say that it works.

Note:

With any "exotic" wheels (carbon, low spoke count, "aero" spokes etc.) it gets even trickier to work without a tensiometer (it can be expensive if you overdo the spoke tension and the expensive "plastic" rim cracks).

A digression:

Having said that, for me at least, it is easier and faster to work with a tensiometer, compared to using a pluck, even with "normal" aluminium rims.

That is problably because I am practically incapable of discerning different tones (my hearing is fine, but playing or singing... nope

).

).However, based on the feedback from "normal" people (and a couple of musicians

), pluck can be more accurate than using a "standard" tension meter (the likes sold by DT Swiss, Park Tool and the others) - but, again, that doesn't really measure the absolute tension.

), pluck can be more accurate than using a "standard" tension meter (the likes sold by DT Swiss, Park Tool and the others) - but, again, that doesn't really measure the absolute tension.So, you could build a good wheel without a tensiometer, but it might be a bit faster and easier if you use it.

Relja

#94

Senior Member

Join Date: Apr 2011

Posts: 7,077

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4416 Post(s)

Liked 1,569 Times

in

1,031 Posts

Good points.

To answer the question:

Tensiometer can tell you the absolute spoke tension

(while plucking the spokes basically tells you only their relative tensions between each other).

For a novice builder, I suppose that knowing the absolute tension can help prevent building wheels that are under or over-tensioned (even if the tension is uniform).

Yes, I suppose you could calculate the absolute tension based on the spoke length, thickness, material, and measuring frequency, but I think using a tensiometer is simpler.

A solution to that problem, without using a tensiometer (and with the relatively thin bicycle spokes), is to rely on hand feel - and check what a wheel that you know is well-tensioned feels like (its spokes that is).

This has worked well for me in practice, so I would say that it works.

Note:

With any "exotic" wheels (carbon, low spoke count, "aero" spokes etc.) it gets even trickier to work without a tensiometer (it can be expensive if you overdo the spoke tension and the expensive "plastic" rim cracks).

A digression:

Having said that, for me at least, it is easier and faster to work with a tensiometer, compared to using a pluck, even with "normal" aluminium rims.

That is problably because I am practically incapable of discerning different tones (my hearing is fine, but playing or singing... nope ).

).

However, based on the feedback from "normal" people (and a couple of musicians ), pluck can be more accurate than using a "standard" tension meter (the likes sold by DT Swiss, Park Tool and the others) - but, again, that doesn't really measure the absolute tension.

), pluck can be more accurate than using a "standard" tension meter (the likes sold by DT Swiss, Park Tool and the others) - but, again, that doesn't really measure the absolute tension.

So, you could build a good wheel without a tensiometer, but it might be a bit faster and easier if you use it.

Relja

To answer the question:

Tensiometer can tell you the absolute spoke tension

(while plucking the spokes basically tells you only their relative tensions between each other).

For a novice builder, I suppose that knowing the absolute tension can help prevent building wheels that are under or over-tensioned (even if the tension is uniform).

Yes, I suppose you could calculate the absolute tension based on the spoke length, thickness, material, and measuring frequency, but I think using a tensiometer is simpler.

A solution to that problem, without using a tensiometer (and with the relatively thin bicycle spokes), is to rely on hand feel - and check what a wheel that you know is well-tensioned feels like (its spokes that is).

This has worked well for me in practice, so I would say that it works.

Note:

With any "exotic" wheels (carbon, low spoke count, "aero" spokes etc.) it gets even trickier to work without a tensiometer (it can be expensive if you overdo the spoke tension and the expensive "plastic" rim cracks).

A digression:

Having said that, for me at least, it is easier and faster to work with a tensiometer, compared to using a pluck, even with "normal" aluminium rims.

That is problably because I am practically incapable of discerning different tones (my hearing is fine, but playing or singing... nope

).

).However, based on the feedback from "normal" people (and a couple of musicians

), pluck can be more accurate than using a "standard" tension meter (the likes sold by DT Swiss, Park Tool and the others) - but, again, that doesn't really measure the absolute tension.

), pluck can be more accurate than using a "standard" tension meter (the likes sold by DT Swiss, Park Tool and the others) - but, again, that doesn't really measure the absolute tension.So, you could build a good wheel without a tensiometer, but it might be a bit faster and easier if you use it.

Relja

#95

Senior Member

Join Date: Apr 2005

Location: Northern CA

Posts: 743

Bikes: Cannondale tandems: '92 Road, '97 Mtn. Mongoose 10.9 Ti, Kelly Deluxe, Tommaso Chorus, Cdale MT2000, Schwinn Deluxe Cruiser, Torker Unicycle, among others.

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 279 Post(s)

Liked 207 Times

in

129 Posts

#96

Senior Member

Join Date: Apr 2005

Location: Northern CA

Posts: 743

Bikes: Cannondale tandems: '92 Road, '97 Mtn. Mongoose 10.9 Ti, Kelly Deluxe, Tommaso Chorus, Cdale MT2000, Schwinn Deluxe Cruiser, Torker Unicycle, among others.

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 279 Post(s)

Liked 207 Times

in

129 Posts

"However, based on the feedback from "normal" people (and a couple of musicians  ), pluck can be more accurate than using a "standard" tension meter (the likes sold by DT Swiss, Park Tool and the others) - but, again, that doesn't really measure the absolute tension."

), pluck can be more accurate than using a "standard" tension meter (the likes sold by DT Swiss, Park Tool and the others) - but, again, that doesn't really measure the absolute tension."

It does if you utilize a tension meter calibrator! My tension meter came with an outdated and practically useless "deflection/tension values" chart for three stainless steel spokes. And then I was servicing Mavic Ksyrium wheels with their proprietary spokes. And then CX Ray spokes, among several others. So I realized a calibration tool would be ideal. I followed Dan Burkhardt's design and quickly built one out of hardwood. Not quite as ideal as square metal tubing, but it suffices. Given all the different spoke materials and shapes today, calibrating a tension meter to spokes being used makes sense. Plus, your tension meter may get dropped or otherwise abused, so after a year or two of use, you're not going to be confident it's still calibrated.

I find this very useful as my favorite hubs, Chris King, have a 120 kgf max tension specification, so I really want to know I'm not exceeding their spec.

It's nice to know now that I do actually know my absolute tension values, as well as the fact that I'm building wheels with even tension. No more guesswork or uncertainty (within margin of error, of course!).

), pluck can be more accurate than using a "standard" tension meter (the likes sold by DT Swiss, Park Tool and the others) - but, again, that doesn't really measure the absolute tension."

), pluck can be more accurate than using a "standard" tension meter (the likes sold by DT Swiss, Park Tool and the others) - but, again, that doesn't really measure the absolute tension."It does if you utilize a tension meter calibrator! My tension meter came with an outdated and practically useless "deflection/tension values" chart for three stainless steel spokes. And then I was servicing Mavic Ksyrium wheels with their proprietary spokes. And then CX Ray spokes, among several others. So I realized a calibration tool would be ideal. I followed Dan Burkhardt's design and quickly built one out of hardwood. Not quite as ideal as square metal tubing, but it suffices. Given all the different spoke materials and shapes today, calibrating a tension meter to spokes being used makes sense. Plus, your tension meter may get dropped or otherwise abused, so after a year or two of use, you're not going to be confident it's still calibrated.

I find this very useful as my favorite hubs, Chris King, have a 120 kgf max tension specification, so I really want to know I'm not exceeding their spec.

It's nice to know now that I do actually know my absolute tension values, as well as the fact that I'm building wheels with even tension. No more guesswork or uncertainty (within margin of error, of course!).

#97

Junior Member

I don't know if one is better than the other, but I use both. Tone to build and true and the tension meter for a final double check. Usually without needing adjustments.

I have an ear for music, so i can pick up the tone very easily.

I have an ear for music, so i can pick up the tone very easily.

#98

Senior Member

Join Date: Jul 2014

Posts: 1,490

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 1084 Post(s)

Liked 687 Times

in

441 Posts

Except that frequencies have a base two logarithmic relationship to pitch. 20% higher (or lower) in numeric frequency does not equate to a 20% variance in musical pitch, and would not translate to 20% variance in spoke tension.

Last edited by Jeff Neese; 11-19-23 at 07:14 PM.

#99

Senior Member

Join Date: Apr 2011

Posts: 7,077

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4416 Post(s)

Liked 1,569 Times

in

1,031 Posts

I don't understand the fascination with 20%. That number exists in part to educate us that the acceptable range of base spoke tensions in a quality wheel is quite large. There isn't a "correct" tension.

#100

Senior Member

Join Date: Apr 2010

Location: Elevation 666m Edmonton Canada

Posts: 2,484

Bikes: 2013 Custom SA5w / Rohloff Tourster

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 1237 Post(s)

Liked 324 Times

in

249 Posts

My last 2 builds I didn't use any gauges. One Co-op is still playing hospital. Pfffft

My fork is always the stand anyway. I use a piece of black tape for the round and just hold a piece of plastic for the side.

Did the flipflop for centering.

For finish tension I use my thumb and fingers to squeeze parallel spokes, same as what the tool does. Too loose is obvious. When too tight they only squeeze a mm and get hard to turn the nipple. Each spoke bending about 2 mm is about right, for mine anyway.

After a year it likely needs tightening when the holes settle in.

So is the OP doing the same thing over and over and expecting a magic diff result, or getting 2.3/ 2.0 spokes?? LOL.

My fork is always the stand anyway. I use a piece of black tape for the round and just hold a piece of plastic for the side.

Did the flipflop for centering.

For finish tension I use my thumb and fingers to squeeze parallel spokes, same as what the tool does. Too loose is obvious. When too tight they only squeeze a mm and get hard to turn the nipple. Each spoke bending about 2 mm is about right, for mine anyway.

After a year it likely needs tightening when the holes settle in.

So is the OP doing the same thing over and over and expecting a magic diff result, or getting 2.3/ 2.0 spokes?? LOL.

Last edited by GamblerGORD53; 11-19-23 at 09:20 PM.