Loose ball bearing size for front axle Sirrus 2.0

#1

Newbie

Thread Starter

Loose ball bearing size for front axle Sirrus 2.0

I have a Specialized Sirrus 2.0 purchased 2020.

I no longer have the original (loose) axle ball bearings for the front and rear.

The back seems to be 9 x 1/4" on each side.

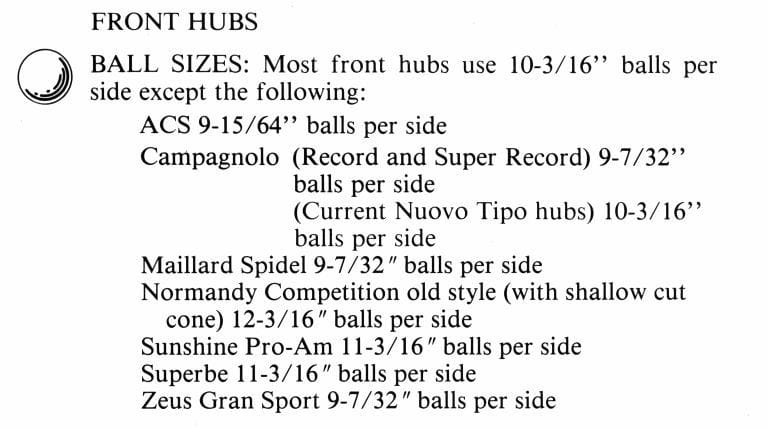

For the front, I can't tell if should be 10 x 3/16" or 9 x 1/4" per side.

Does anyone here know the answer? Or know a way to determine what size the ball bearings should be?

Thanks

I no longer have the original (loose) axle ball bearings for the front and rear.

The back seems to be 9 x 1/4" on each side.

For the front, I can't tell if should be 10 x 3/16" or 9 x 1/4" per side.

Does anyone here know the answer? Or know a way to determine what size the ball bearings should be?

Thanks

#2

Really Old Senior Member

Does it have a Shimano hub? One could look up the docs if they knew the model #.

The only bikes I've seen with 1/4" balls in front were Huffy's. That certainly doesn't mean it's not impossible to have other sizes, but I'd expect 3/16"

Another reason to buy 100 packs of BB's of the sizes you use. You're already prepared.

BTW, how long does it take to remove the wheel and back off a cone a ways and look?

The only bikes I've seen with 1/4" balls in front were Huffy's. That certainly doesn't mean it's not impossible to have other sizes, but I'd expect 3/16"

Another reason to buy 100 packs of BB's of the sizes you use. You're already prepared.

BTW, how long does it take to remove the wheel and back off a cone a ways and look?

#3

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,729

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,593 Times

in

1,437 Posts

I assume you no longer have the originals. As noted front hubs with 1/4" balls are rare, but not unheard of. If you have stock in both sizes, an easy trial and error method should give you the answer.

The different sized balls will stack axially by different amounts. So, assemble the hub with either size and measure the OLD, or note the amount the cone extends past the dust cap, compared to marks which might show prior position.

The different sized balls will stack axially by different amounts. So, assemble the hub with either size and measure the OLD, or note the amount the cone extends past the dust cap, compared to marks which might show prior position.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

Likes For FBinNY:

#4

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,100

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4212 Post(s)

Liked 3,883 Times

in

2,318 Posts

Most likely 3/16" x 10. One can mark the cone's curved ball surface with marker then assemble the hub with the best guess (3/16") balls with 1 less ball then you think (from 10 to 9 in this case) dry of any lube. Adjust the preload a hair tight and spin the axle a bunch. Take it all apart and you'll see where on that curved surface the ball track is. The correct ball diameter and more than half the correct ball count will produce the contract track, showing by the removed marking only where there's contact. If a too large ball is used that contract track will be at the VERY small end of the surface. The correct ball size will have the track only within the ends of the curved surface, usually towards the middle portion. Clean it all up and install with the now known correct ball size.

As to how many balls are correct- one too many will result in a hard time getting the preload adjustment spot on (generally it goes from too loose to too tight with VERY little additional preload) and the rim will now look to be out of true. That extra 1 too many balls will ride up within the "ring of balls". If one were to try to true the rim now the deviation will seem to travel about the wheel as that ball cocks the wheel off angle. This off angle usually rotates at about half the RPM of the wheel. One few balls is OK but not advised.

There have been some alloy "nice" hubs with 1/4" balls. The BMX world is well known for this. Andy

As to how many balls are correct- one too many will result in a hard time getting the preload adjustment spot on (generally it goes from too loose to too tight with VERY little additional preload) and the rim will now look to be out of true. That extra 1 too many balls will ride up within the "ring of balls". If one were to try to true the rim now the deviation will seem to travel about the wheel as that ball cocks the wheel off angle. This off angle usually rotates at about half the RPM of the wheel. One few balls is OK but not advised.

There have been some alloy "nice" hubs with 1/4" balls. The BMX world is well known for this. Andy

__________________

AndrewRStewart

AndrewRStewart

Likes For Andrew R Stewart:

#6

Old fart

Join Date: Nov 2004

Location: Appleton WI

Posts: 24,792

Bikes: Several, mostly not name brands.

Mentioned: 153 Post(s)

Tagged: 0 Thread(s)

Quoted: 3591 Post(s)

Liked 3,401 Times

in

1,935 Posts

Some front hubs will use 7/32" balls. It's hard to know what your hub needs without knowing the make and model of the hub. If you have the tools, open the hub and take a look.

Likes For JohnDThompson:

#8

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,100

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4212 Post(s)

Liked 3,883 Times

in

2,318 Posts

Jeff- I've heard this suggestion so many times over the years. While I do agree with using as high quality a part as one can afford I also feel there's a point of diminishing returns at play. So many other conditions grow with time that will overwhelm the tiny added tolerance control of a more costly set of balls. Wobbling axles (rear on freewheel hubs being very common), cone wear from the previous condition not being caught/serviced before further use, poor hub construction (especially on multi piece hubs) and the inability or lack of follow up bearing preload adjustments after the factory assembly are all common examples.

I can't say how many loose ball/cup and cone bearing systems I have serviced with reusing the old balls (only if they are still consistently shinny) and cones. Maybe in the hundreds by now. I also can't say how few returns have been due to bearing issues that I could have replaced (and I don't include the pressed in ball cup cracking failures in this) because I didn't have any that I remember. I have had returns from my mistakenly replacing cones with ones that didn't match the ball track surfaces, from using the wrong size balls (and this is avoided if the old balls were able to be reused) and from the wrong ball count (only did this a very few times way back when, but that's how I learned about this affecting rim true too).

When I work on high end stuff I do pay more attention to ball tolerance claims however I still feel that this is a topic that has greater discussion interest than actual performance effects. Andy

I can't say how many loose ball/cup and cone bearing systems I have serviced with reusing the old balls (only if they are still consistently shinny) and cones. Maybe in the hundreds by now. I also can't say how few returns have been due to bearing issues that I could have replaced (and I don't include the pressed in ball cup cracking failures in this) because I didn't have any that I remember. I have had returns from my mistakenly replacing cones with ones that didn't match the ball track surfaces, from using the wrong size balls (and this is avoided if the old balls were able to be reused) and from the wrong ball count (only did this a very few times way back when, but that's how I learned about this affecting rim true too).

When I work on high end stuff I do pay more attention to ball tolerance claims however I still feel that this is a topic that has greater discussion interest than actual performance effects. Andy

__________________

AndrewRStewart

AndrewRStewart

Likes For Andrew R Stewart:

#9

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,729

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,593 Times

in

1,437 Posts

Grade 25 is what's used on electric motor bearings rated for well over 10,000 hours of continued service at 3,600rpm.

Better grades are generally reserved for higher speed applications where vibration is a serious concern. The higher precision comes with s considerable cost premium.

As it is, grade 25 is well above what's necessary for bicycles. I buy them because, given the volume, the cost difference is small. But I don't fool myself into believing it makes a difference.

FWIW typical bike cup/cone systems are supplied with grade 100 balls, and only elite brands using grade 25.

Better grades are generally reserved for higher speed applications where vibration is a serious concern. The higher precision comes with s considerable cost premium.

As it is, grade 25 is well above what's necessary for bicycles. I buy them because, given the volume, the cost difference is small. But I don't fool myself into believing it makes a difference.

FWIW typical bike cup/cone systems are supplied with grade 100 balls, and only elite brands using grade 25.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

#10

Senior Member

Join Date: Jul 2014

Posts: 1,490

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 1084 Post(s)

Liked 687 Times

in

441 Posts

Grade 25 is what's used on electric motor bearings rated for well over 10,000 hours of continued service at 3,600rpm.

Better grades are generally reserved for higher speed applications where vibration is a serious concern. The higher precision comes with s considerable cost premium.

As it is, grade 25 is well above what's necessary for bicycles. I buy them because, given the volume, the cost difference is small. But I don't fool myself into believing it makes a difference.

FWIW typical bike cup/cone systems are supplied with grade 100 balls, and only elite brands using grade 25.

Better grades are generally reserved for higher speed applications where vibration is a serious concern. The higher precision comes with s considerable cost premium.

As it is, grade 25 is well above what's necessary for bicycles. I buy them because, given the volume, the cost difference is small. But I don't fool myself into believing it makes a difference.

FWIW typical bike cup/cone systems are supplied with grade 100 balls, and only elite brands using grade 25.

3/16 INCH Chrome Ball, Grade 25, (100 Count)

#11

Senior Member

Join Date: Jul 2014

Posts: 1,490

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 1084 Post(s)

Liked 687 Times

in

441 Posts

Jeff- I've heard this suggestion so many times over the years. While I do agree with using as high quality a part as one can afford I also feel there's a point of diminishing returns at play. ....

.....

When I work on high end stuff I do pay more attention to ball tolerance claims however I still feel that this is a topic that has greater discussion interest than actual performance effects. Andy

.....

When I work on high end stuff I do pay more attention to ball tolerance claims however I still feel that this is a topic that has greater discussion interest than actual performance effects. Andy

#12

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,729

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,593 Times

in

1,437 Posts

Typical high-quality hubs (Shimano, for example) use grade 25. I've seen reference to Campy using grade 10, and bike shops will recommend grade 10 for rebuilding Campy hubs. I would tend to believe that Walmart bikes probably use either grade 100 or worse. Grade 25 is good enough though, and they're certainly cheap enough that there's no reason to go lower quality. These are what I use - about $6 for a pack of 100.

3/16 INCH Chrome Ball, Grade 25, (100 Count)

3/16 INCH Chrome Ball, Grade 25, (100 Count)

Last edited by FBinNY; 01-05-24 at 03:38 PM.

Likes For FBinNY:

#13

Full Member

Drop the ball bearings as necessary, ensuring they are flush with the surface. Do not overlap them.

If the front takes 9 instead of 10 and the rear takes 8 instead of 9 on one side or both sides, so be it. Recently, when I repacked my front hub, I removed 10 worn ball bearings from each side. However, when filling it with new ones, I only used 9, and 10th one ended-up overlapping and was unnecessary. Knock on wood, my bike rides great, since repacking.

If the front takes 9 instead of 10 and the rear takes 8 instead of 9 on one side or both sides, so be it. Recently, when I repacked my front hub, I removed 10 worn ball bearings from each side. However, when filling it with new ones, I only used 9, and 10th one ended-up overlapping and was unnecessary. Knock on wood, my bike rides great, since repacking.

#16

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,100

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4212 Post(s)

Liked 3,883 Times

in

2,318 Posts

I'm not arguing that we should all toss out our grade whatever balls we use and only get the cheapest possible (a bit of embellishment here) but that if we did drop a grade I don't think anyone here would notice. The cleaned and freshly lubed condition will be vastly more noticeable. Andy

__________________

AndrewRStewart

AndrewRStewart

Likes For Andrew R Stewart:

#17

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,729

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,593 Times

in

1,437 Posts

OTOH engineers whose entire focus is on bearings, generally consider grade 25 suitable for commercial and industrial bearings, reserving finer grades for higher speeds (well above 3600rpm) where vibration becomes a greater problem.

So, if you choose to paint the lily, by all means go ahead and use grade 10, otherwise grade 25 is fine.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

Likes For FBinNY:

#18

Senior Member

Join Date: Mar 2012

Posts: 982

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 506 Post(s)

Likes: 0

Liked 639 Times

in

357 Posts

I make it a policy never to argue with those not present. So I don't claim to know better than the folks at Campagnolo, nor do I challenge their decision, which may be based on a variety of considerations.

OTOH engineers whose entire focus is on bearings, generally consider grade 25 suitable for commercial and industrial bearings, reserving finer grades for higher speeds (well above 3600rpm) where vibration becomes a greater problem.

So, if you choose to paint the lily, by all means go ahead and use grade 10, otherwise grade 25 is fine.

OTOH engineers whose entire focus is on bearings, generally consider grade 25 suitable for commercial and industrial bearings, reserving finer grades for higher speeds (well above 3600rpm) where vibration becomes a greater problem.

So, if you choose to paint the lily, by all means go ahead and use grade 10, otherwise grade 25 is fine.

#19

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,729

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,593 Times

in

1,437 Posts

I bought my first Campagnolo Record equipped bike in 1967 and, like you, enjoyed many 10s of thousands of trouble and wear free miles.

But, I chalk it up to better steel and greater precision in cups and cones rather than better balls.

The difference in the tolerance if G10 vs. G25 is miniscule compared to the precision of the other parts, and certainly far smaller than what anyone could sense in a manual bearing adjustment, especially those assembling components in production.

In any case, your analogy is flawed. Big balls don't get squeezed into a tight space. Instead the axle is triangulated between the three closest balls, with the other balls doing less work, If 3 large balls are roughly equally spaced, all is good, but the odds are that they're not, causing the axle to and down as smaller balls pass below. It's not much and bearing can handle it, but harmonics can make that tiny movement problematic at high speeds.

So, I'll trust the judgement of folks at bearing companies like skf who reserve higher grades for especially demanding applications.

But, I chalk it up to better steel and greater precision in cups and cones rather than better balls.

The difference in the tolerance if G10 vs. G25 is miniscule compared to the precision of the other parts, and certainly far smaller than what anyone could sense in a manual bearing adjustment, especially those assembling components in production.

In any case, your analogy is flawed. Big balls don't get squeezed into a tight space. Instead the axle is triangulated between the three closest balls, with the other balls doing less work, If 3 large balls are roughly equally spaced, all is good, but the odds are that they're not, causing the axle to and down as smaller balls pass below. It's not much and bearing can handle it, but harmonics can make that tiny movement problematic at high speeds.

So, I'll trust the judgement of folks at bearing companies like skf who reserve higher grades for especially demanding applications.

Last edited by FBinNY; 01-08-24 at 01:25 PM.