Vintage touring bikes: which ones have internal routing for dynamo wiring?

#1

Senior Member

Thread Starter

Join Date: Jul 2011

Posts: 1,268

Mentioned: 12 Post(s)

Tagged: 0 Thread(s)

Quoted: 414 Post(s)

Liked 692 Times

in

288 Posts

Vintage touring bikes: which ones have internal routing for dynamo wiring?

Hey gang,

Looking to get a vintage bike/frame that has a fork that will allow internal wiring of a front dynamo hub... any ideas? I can't stand the sight of the wires wrapped around the fork (I know, issues...). Or, am I better off trying to find a new off-the-shelf steel bike frame? I tried checking the Velo Orange, Surly and Kona sites but can't figure out which frames will allow this... I saw a thread here about a vintage Koga Miyata bike that would work, but that would be like looking for a needle in a haystack. Thanks in advance!

Looking to get a vintage bike/frame that has a fork that will allow internal wiring of a front dynamo hub... any ideas? I can't stand the sight of the wires wrapped around the fork (I know, issues...). Or, am I better off trying to find a new off-the-shelf steel bike frame? I tried checking the Velo Orange, Surly and Kona sites but can't figure out which frames will allow this... I saw a thread here about a vintage Koga Miyata bike that would work, but that would be like looking for a needle in a haystack. Thanks in advance!

#2

Senior Member

You can frequently sneak the thin 2-conductor BuMM wires through vent holes in the fork. If you have the light mounted to a conductive surface, you can even typically "get away" with one wire, provided the hub grounds to the axle.

Using vent holes (which I will admit: can be super frustrating) opens you up to pretty much every bike outside of the fancy-schmancy stuff where the builder was showing off, and silver-brazed the vents closed.

Using vent holes (which I will admit: can be super frustrating) opens you up to pretty much every bike outside of the fancy-schmancy stuff where the builder was showing off, and silver-brazed the vents closed.

#3

Senior Member

Join Date: Jun 2010

Location: Medford MA

Posts: 2,089

Bikes: Ron Cooper touring, 1959 Jack Taylor 650b ladyback touring tandem, Vitus 979, Joe Bell painted Claud Butler Dalesman, Colin Laing curved tube tandem, heavily-Dilberted 1982 Trek 6xx, René Herse tandem

Mentioned: 80 Post(s)

Tagged: 0 Thread(s)

Quoted: 964 Post(s)

Liked 1,451 Times

in

723 Posts

Pretty much no bike will have internal fork wiring from-factory.

Specialized Expedition had internal wiring, along with a couple of Koga-Miyata touring bikes from the '80s. Also many French randonneuses.

The trouble with all these is, they were built for "bottle" dynamos or under-bb dynamos, which won't run wiring down a fork blade.

On most all bikes that do have internal wiring, the wire is just running through plain holes, sometimes reinforced with a grommet or other such thing. It's not complicated to do this yourself, just very tedious. Even René Herse did his wiring like this. The wires are reinforced with braided sheath where they go in and out of the frame, and that's it. The only old builder I know of who used internal conduits is Jack Taylor, and then only on a very few frames.

I have threaded wires through a multitude of forks. Mostly Nishiki tourers (usually super easy), Miyatas and Univegas, a Huffy-era Raleigh, Schwinn Voyageur SP, as well as a Trek or two. You push a derailleur cable through from the top. Put a curved end on it, and either glue or solder the end to make sure it doesn't fray while you're pushing it inside. You push it all the way through to the bottom of the fork, then turn it until the curved end pokes through the vent hole near the dropout. Might take a couple tries to get the curved end right. It's got to be curved enough to poke out, but not so curved that it forms a U-loop inside the fork. Then solder the actual lighting wire onto the cable and use the cable to pull the wire through. It is often possible, except when it isn't. This will depend on the fork crown and pre-drilled vent holes.

Once I built a fork with an internal conduit. It was a HUGE pain to build. Would not recommend, not for the faint of heart. That said, it is super slick. The ne plus ultra of dynamo wiring.

With patience, you can be most of the way there by threading your own fork, if you find one with a hollow crown, with holes all the way through, and that is not super snaggy inside.

I favor a single-conductor wire over the two-conductor. Shimano hubs ground to the axle. Sanyo I think as well. SP and Schmidt do not, but you can ground them, like Peter Weigle did here:

I did this to my Schmidt and have had no trouble with single-conductor wiring. Cases where it might not work include plastique headsets such as the Stronglight B10.

Specialized Expedition had internal wiring, along with a couple of Koga-Miyata touring bikes from the '80s. Also many French randonneuses.

The trouble with all these is, they were built for "bottle" dynamos or under-bb dynamos, which won't run wiring down a fork blade.

On most all bikes that do have internal wiring, the wire is just running through plain holes, sometimes reinforced with a grommet or other such thing. It's not complicated to do this yourself, just very tedious. Even René Herse did his wiring like this. The wires are reinforced with braided sheath where they go in and out of the frame, and that's it. The only old builder I know of who used internal conduits is Jack Taylor, and then only on a very few frames.

I have threaded wires through a multitude of forks. Mostly Nishiki tourers (usually super easy), Miyatas and Univegas, a Huffy-era Raleigh, Schwinn Voyageur SP, as well as a Trek or two. You push a derailleur cable through from the top. Put a curved end on it, and either glue or solder the end to make sure it doesn't fray while you're pushing it inside. You push it all the way through to the bottom of the fork, then turn it until the curved end pokes through the vent hole near the dropout. Might take a couple tries to get the curved end right. It's got to be curved enough to poke out, but not so curved that it forms a U-loop inside the fork. Then solder the actual lighting wire onto the cable and use the cable to pull the wire through. It is often possible, except when it isn't. This will depend on the fork crown and pre-drilled vent holes.

Once I built a fork with an internal conduit. It was a HUGE pain to build. Would not recommend, not for the faint of heart. That said, it is super slick. The ne plus ultra of dynamo wiring.

With patience, you can be most of the way there by threading your own fork, if you find one with a hollow crown, with holes all the way through, and that is not super snaggy inside.

I favor a single-conductor wire over the two-conductor. Shimano hubs ground to the axle. Sanyo I think as well. SP and Schmidt do not, but you can ground them, like Peter Weigle did here:

I did this to my Schmidt and have had no trouble with single-conductor wiring. Cases where it might not work include plastique headsets such as the Stronglight B10.

__________________

Owner & co-founder, Cycles René Hubris. Unfortunately attaching questionable braze-ons to perfectly good frames since about 2015. With style.

Owner & co-founder, Cycles René Hubris. Unfortunately attaching questionable braze-ons to perfectly good frames since about 2015. With style.

Last edited by scarlson; 04-24-23 at 05:26 PM.

Likes For scarlson:

#4

Senior Member

Join Date: Dec 2005

Posts: 17,160

Mentioned: 481 Post(s)

Tagged: 0 Thread(s)

Quoted: 3811 Post(s)

Liked 6,717 Times

in

2,614 Posts

I've never tried to feed a dynamo wire through a fork--seems quite challenging! However, I have glued the wire in multiple places to the inside of the fork blade using silicon adhesive (so easily removable). You can pretty much make the wire invisible unless one were really looking for it.

Likes For nlerner:

#5

Senior Member

Thread Starter

Join Date: Jul 2011

Posts: 1,268

Mentioned: 12 Post(s)

Tagged: 0 Thread(s)

Quoted: 414 Post(s)

Liked 692 Times

in

288 Posts

Pretty much no bike will have internal fork wiring from-factory.

Specialized Expedition had internal wiring, along with a couple of Koga-Miyata touring bikes from the '80s. Also many French randonneuses.

The trouble with all these is, they were built for "bottle" dynamos or under-bb dynamos, which won't run wiring down a fork blade.

On most all bikes that do have internal wiring, the wire is just running through plain holes, sometimes reinforced with a grommet or other such thing. It's not complicated to do this yourself, just very tedious. Even René Herse did his wiring like this. The wires are reinforced with braided sheath where they go in and out of the frame, and that's it. The only old builder I know of who used internal conduits is Jack Taylor, and then only on a very few frames.

I have threaded wires through a multitude of forks. Mostly Nishiki tourers (usually super easy), Miyatas and Univegas, a Huffy-era Raleigh, Schwinn Voyageur SP, as well as a Trek or two. You push a derailleur cable through from the top. Put a curved end on it, and either glue or solder the end to make sure it doesn't fray while you're pushing it inside. You push it all the way through to the bottom of the fork, then turn it until the curved end pokes through the vent hole near the dropout. Might take a couple tries to get the curved end right. It's got to be curved enough to poke out, but not so curved that it forms a U-loop inside the fork. Then solder the actual lighting wire onto the cable and use the cable to pull the wire through. It is often possible, except when it isn't. This will depend on the fork crown and pre-drilled vent holes.

Once I built a fork with an internal conduit. It was a HUGE pain to build. Would not recommend, not for the faint of heart. That said, it is super slick. The ne plus ultra of dynamo wiring.

With patience, you can be most of the way there by threading your own fork, if you find one with a hollow crown, with holes all the way through, and that is not super snaggy inside.

I favor a single-conductor wire over the two-conductor. Shimano hubs ground to the axle. Sanyo I think as well. SP and Schmidt do not, but you can ground them, like Peter Weigle did here:

I did this to my Schmidt and have had no trouble with single-conductor wiring. Cases where it might not work include plastique headsets such as the Stronglight B10.

Specialized Expedition had internal wiring, along with a couple of Koga-Miyata touring bikes from the '80s. Also many French randonneuses.

The trouble with all these is, they were built for "bottle" dynamos or under-bb dynamos, which won't run wiring down a fork blade.

On most all bikes that do have internal wiring, the wire is just running through plain holes, sometimes reinforced with a grommet or other such thing. It's not complicated to do this yourself, just very tedious. Even René Herse did his wiring like this. The wires are reinforced with braided sheath where they go in and out of the frame, and that's it. The only old builder I know of who used internal conduits is Jack Taylor, and then only on a very few frames.

I have threaded wires through a multitude of forks. Mostly Nishiki tourers (usually super easy), Miyatas and Univegas, a Huffy-era Raleigh, Schwinn Voyageur SP, as well as a Trek or two. You push a derailleur cable through from the top. Put a curved end on it, and either glue or solder the end to make sure it doesn't fray while you're pushing it inside. You push it all the way through to the bottom of the fork, then turn it until the curved end pokes through the vent hole near the dropout. Might take a couple tries to get the curved end right. It's got to be curved enough to poke out, but not so curved that it forms a U-loop inside the fork. Then solder the actual lighting wire onto the cable and use the cable to pull the wire through. It is often possible, except when it isn't. This will depend on the fork crown and pre-drilled vent holes.

Once I built a fork with an internal conduit. It was a HUGE pain to build. Would not recommend, not for the faint of heart. That said, it is super slick. The ne plus ultra of dynamo wiring.

With patience, you can be most of the way there by threading your own fork, if you find one with a hollow crown, with holes all the way through, and that is not super snaggy inside.

I favor a single-conductor wire over the two-conductor. Shimano hubs ground to the axle. Sanyo I think as well. SP and Schmidt do not, but you can ground them, like Peter Weigle did here:

I did this to my Schmidt and have had no trouble with single-conductor wiring. Cases where it might not work include plastique headsets such as the Stronglight B10.

#6

Senior Member

Thread Starter

Join Date: Jul 2011

Posts: 1,268

Mentioned: 12 Post(s)

Tagged: 0 Thread(s)

Quoted: 414 Post(s)

Liked 692 Times

in

288 Posts

I've never tried to feed a dynamo wire through a fork--seems quite challenging! However, I have glued the wire in multiple places to the inside of the fork blade using silicon adhesive (so easily removable). You can pretty much make the wire invisible unless one were really looking for it.

#7

Full Member

Join Date: Oct 2022

Location: UK, New Forest

Posts: 269

Bikes: 1980 Gitane sprint,1977 Motobécane C4, 1977 Carlton Clubman, 1959 Claud Butler European

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 69 Post(s)

Liked 122 Times

in

78 Posts

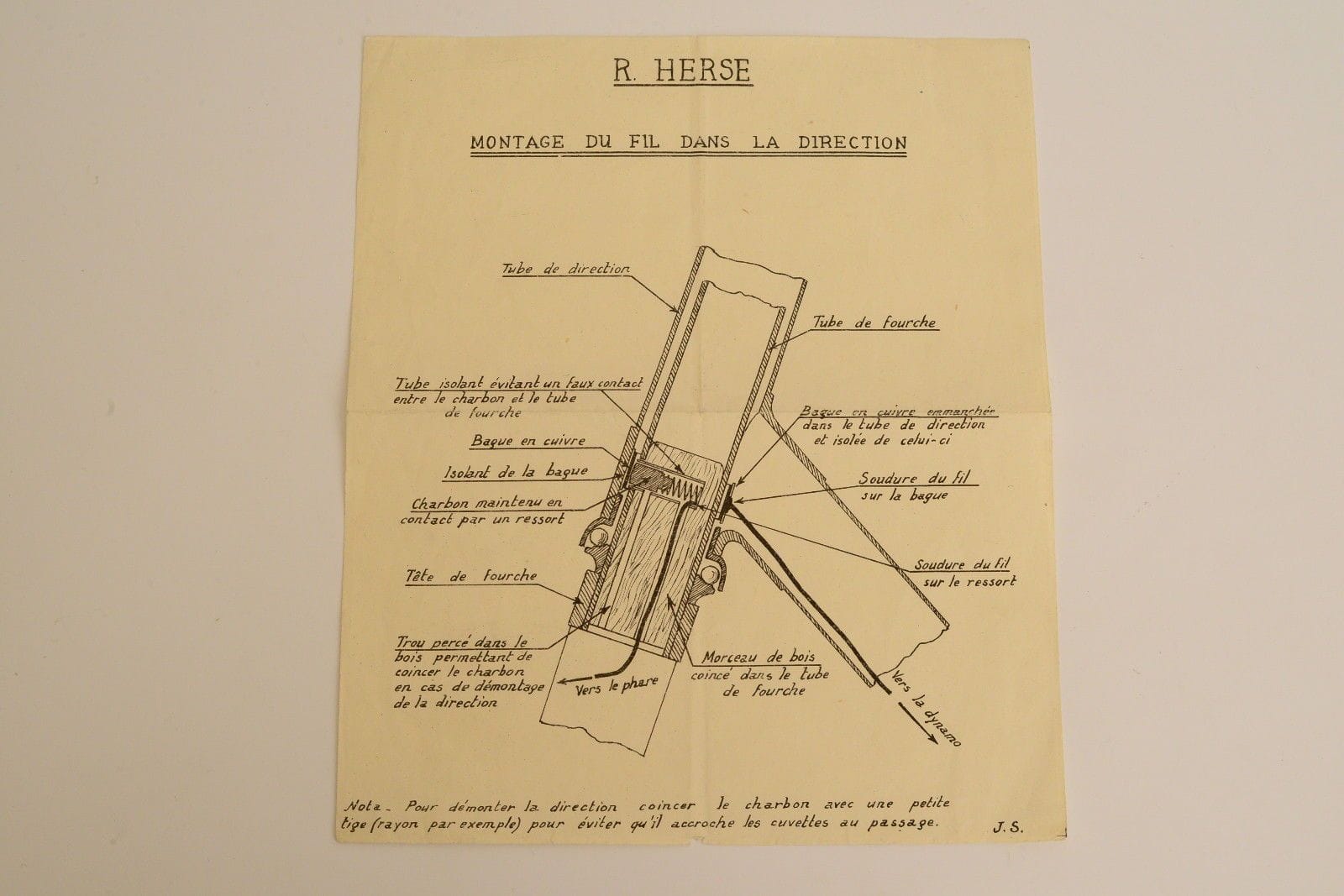

R. Herse head wire

Thought this might be of interest, found it while surfing around a few weeks ago.

Likes For awac:

#8

Full Member

Join Date: Sep 2019

Posts: 393

Mentioned: 18 Post(s)

Tagged: 0 Thread(s)

Quoted: 170 Post(s)

Liked 264 Times

in

146 Posts

Hey gang,

Looking to get a vintage bike/frame that has a fork that will allow internal wiring of a front dynamo hub... any ideas? I can't stand the sight of the wires wrapped around the fork (I know, issues...). Or, am I better off trying to find a new off-the-shelf steel bike frame? I tried checking the Velo Orange, Surly and Kona sites but can't figure out which frames will allow this... I saw a thread here about a vintage Koga Miyata bike that would work, but that would be like looking for a needle in a haystack. Thanks in advance!

Looking to get a vintage bike/frame that has a fork that will allow internal wiring of a front dynamo hub... any ideas? I can't stand the sight of the wires wrapped around the fork (I know, issues...). Or, am I better off trying to find a new off-the-shelf steel bike frame? I tried checking the Velo Orange, Surly and Kona sites but can't figure out which frames will allow this... I saw a thread here about a vintage Koga Miyata bike that would work, but that would be like looking for a needle in a haystack. Thanks in advance!

My '84 Centurion Pro Tour 15 had internal wire routing from the bb to the top of the downtube. Exit hole was pretty basic. Wishful thinking, but would love to see Son partner with SKF to offer a high quality square taper bb dynamo.

Likes For ctak:

#9

Senior Member

Look at some of the industrial supply places. You can get large heat shrink tubing in clear. You could either shrink bands of clear to hold the wire or slip over the whole fork leg and shrink it. Not sure how well that would hold up to abrasion would be my concern.

Likes For etherhuffer:

#10

Senior Member

Join Date: Jun 2010

Location: Medford MA

Posts: 2,089

Bikes: Ron Cooper touring, 1959 Jack Taylor 650b ladyback touring tandem, Vitus 979, Joe Bell painted Claud Butler Dalesman, Colin Laing curved tube tandem, heavily-Dilberted 1982 Trek 6xx, René Herse tandem

Mentioned: 80 Post(s)

Tagged: 0 Thread(s)

Quoted: 964 Post(s)

Liked 1,451 Times

in

723 Posts

The Pro Tour is built for one of those under-BB dynamos that clamps between the chainstays, flicks on with a lever, and runs on the tire's tread. I always liked them, they seemed a bit more weatherproof than the sidewall bottle units. My childhood setup (thanks dad!) was one of those, but mounted on the front rack to run on the front tire, right next to the headlight. The tail light was a battery operated blinky. The "fancy" halogen headlight was pretty amazing compared to anything battery operated, at least that we could afford, back in those days.

Of course the modern hubs and LEDs are the 8th wonder of the world, in comparison to what we had then.

__________________

Owner & co-founder, Cycles René Hubris. Unfortunately attaching questionable braze-ons to perfectly good frames since about 2015. With style.

Owner & co-founder, Cycles René Hubris. Unfortunately attaching questionable braze-ons to perfectly good frames since about 2015. With style.

Likes For scarlson:

#11

Senior Member

Join Date: Jul 2007

Location: Manhattan & Woodstock NY

Posts: 2,751

Bikes: 1987 Mercian Pro, 1985 Shogun 500, early '70s Falcon San Remo, 1972 Peugeot PX-10, 1972 Schwinn Paramount P13-9, 1971 Raleigh International, 1971 Peugeot PX-10, 1970 Raleigh Professional Mk1

Mentioned: 109 Post(s)

Tagged: 0 Thread(s)

Quoted: 939 Post(s)

Liked 2,952 Times

in

983 Posts

Nuts. I've been wondering about doing this and I now might be over the edge...

__________________

1987 Mercian Pro, 1985 Shogun 500, 197? Falcon San Remo, 1972 Peugeot PX-10, 1972 Schwinn Paramount P13-9, 1971 Peugeot PX-10, 1971 Raleigh International, 1970 Raleigh Professional Mark I

Curator/Team Mechanic: 2016 Dawes Streetfighter, 1984 Lotus Eclair, 1975 Motobecane Jubile Mixte, 1974 Raleigh Sports, 1973 Free Spirit Ted Williams, 1972 Raleigh Super Course, 1971 Philips Sport

1987 Mercian Pro, 1985 Shogun 500, 197? Falcon San Remo, 1972 Peugeot PX-10, 1972 Schwinn Paramount P13-9, 1971 Peugeot PX-10, 1971 Raleigh International, 1970 Raleigh Professional Mark I

Curator/Team Mechanic: 2016 Dawes Streetfighter, 1984 Lotus Eclair, 1975 Motobecane Jubile Mixte, 1974 Raleigh Sports, 1973 Free Spirit Ted Williams, 1972 Raleigh Super Course, 1971 Philips Sport

Likes For ascherer:

#12

Senior Member

I tried various ways to get a 2-conductor Busch & Muller wire through the fork of my Pro Tour, but couldn't ever manage. I could get it to enter each side, but never snake it through. Eventually I siliconed some small aluminum hobby tubing to the bottom of the fork blade after bending it to match the curve of the fork. I put one under the downtube, too. I run the cable through that tubing. The other part is under my plastic rear fender with silicone dabs and real aluminum duct tape for protection.

I did that 9 years ago, and it's holding up great. That also includes 2 transatlantic moves. As with all things experience, I'd probably be better with my silicone technique if I tried a couple times.

I did that 9 years ago, and it's holding up great. That also includes 2 transatlantic moves. As with all things experience, I'd probably be better with my silicone technique if I tried a couple times.

#13

Garage tetris expert

Join Date: May 2016

Location: Texas Hill Country

Posts: 893

Bikes: A few. Ok, a lot

Mentioned: 16 Post(s)

Tagged: 0 Thread(s)

Quoted: 387 Post(s)

Liked 692 Times

in

329 Posts

My ‘82 Chris Pauley Tierra has wire guides brazed to the fork blade. I’d still use silicone to secure the wires.

Chris Pauley Tierra, dynamo wire guide

Chris Pauley Tierra, dynamo wire guide

#14

Full Member

I tried various ways to get a 2-conductor Busch & Muller wire through the fork of my Pro Tour, but couldn't ever manage. I could get it to enter each side, but never snake it through. Eventually I siliconed some small aluminum hobby tubing to the bottom of the fork blade after bending it to match the curve of the fork. I put one under the downtube, too. I run the cable through that tubing. The other part is under my plastic rear fender with silicone dabs and real aluminum duct tape for protection.

I did that 9 years ago, and it's holding up great. That also includes 2 transatlantic moves. As with all things experience, I'd probably be better with my silicone technique if I tried a couple times.

I did that 9 years ago, and it's holding up great. That also includes 2 transatlantic moves. As with all things experience, I'd probably be better with my silicone technique if I tried a couple times.

#15

Newbie

As others have said, vintage tourers may have internal routing for a BB dynamo, but not for a hub dynamo. My Miyata 1000 has two sets of vent holes on the fork blade - one at the top and one at the bottom. As suggested by others, you could probably route a thin wire through those holes. My Specialized Expedition only has one set of holes (I think), so it wouldn't work on that bike - you'd have to make sure the bike you get has the double vent holes.

#16

Senior Member

Join Date: Jun 2010

Location: Medford MA

Posts: 2,089

Bikes: Ron Cooper touring, 1959 Jack Taylor 650b ladyback touring tandem, Vitus 979, Joe Bell painted Claud Butler Dalesman, Colin Laing curved tube tandem, heavily-Dilberted 1982 Trek 6xx, René Herse tandem

Mentioned: 80 Post(s)

Tagged: 0 Thread(s)

Quoted: 964 Post(s)

Liked 1,451 Times

in

723 Posts

As others have said, vintage tourers may have internal routing for a BB dynamo, but not for a hub dynamo. My Miyata 1000 has two sets of vent holes on the fork blade - one at the top and one at the bottom. As suggested by others, you could probably route a thin wire through those holes. My Specialized Expedition only has one set of holes (I think), so it wouldn't work on that bike - you'd have to make sure the bike you get has the double vent holes.

__________________

Owner & co-founder, Cycles René Hubris. Unfortunately attaching questionable braze-ons to perfectly good frames since about 2015. With style.

Owner & co-founder, Cycles René Hubris. Unfortunately attaching questionable braze-ons to perfectly good frames since about 2015. With style.

#17

ambulatory senior

Join Date: Dec 2016

Location: Peoria Il

Posts: 5,998

Bikes: Austro Daimler modified by Gugie! Raleigh Professional and lots of other bikes.

Mentioned: 76 Post(s)

Tagged: 0 Thread(s)

Quoted: 1956 Post(s)

Liked 3,662 Times

in

1,680 Posts

A BB dynamo that uses the rider's pedaling to generate electricity has never been done, to my knowledge. It would be interesting to know if it is possible, given the diametric constraints and (comparatively) slow rpm.

The Pro Tour is built for one of those under-BB dynamos that clamps between the chainstays, flicks on with a lever, and runs on the tire's tread. I always liked them, they seemed a bit more weatherproof than the sidewall bottle units. My childhood setup (thanks dad!) was one of those, but mounted on the front rack to run on the front tire, right next to the headlight. The tail light was a battery operated blinky. The "fancy" halogen headlight was pretty amazing compared to anything battery operated, at least that we could afford, back in those days.

Of course the modern hubs and LEDs are the 8th wonder of the world, in comparison to what we had then.

The Pro Tour is built for one of those under-BB dynamos that clamps between the chainstays, flicks on with a lever, and runs on the tire's tread. I always liked them, they seemed a bit more weatherproof than the sidewall bottle units. My childhood setup (thanks dad!) was one of those, but mounted on the front rack to run on the front tire, right next to the headlight. The tail light was a battery operated blinky. The "fancy" halogen headlight was pretty amazing compared to anything battery operated, at least that we could afford, back in those days.

Of course the modern hubs and LEDs are the 8th wonder of the world, in comparison to what we had then.

#18

Senior Member

Another wire fishing attempt (sounds like a scam) I've used was to unravel a single wire from the braid of a brake cable wire. The single strand is just stiff enough that you can put a nice hook on the end of your fishing wire and get a bit more control. I then snake the wire through the tubes, pop it out the other side, solder on my electrical wire, and carefully pull the wire back out the way it came. Worked for me after some painful hours trying to get wire through a fork leg. Might work for others.

I needed 2-3 attempts to get the wire through in one piece. Using SON coax, it barely fit through the hole, and was one of the most frustrating things I've ever done; it took 2 tries to get it through the second vent. I gave up for sneaking the wire through the frame itself, and just used two-conductor BuMM wire...which fit in the crimped edge of the fender, anyway.