Seized Bottom Bracket Bearing Cup Races in Aluminum Frames

#1

Newbie

Thread Starter

Seized Bottom Bracket Bearing Cup Races in Aluminum Frames

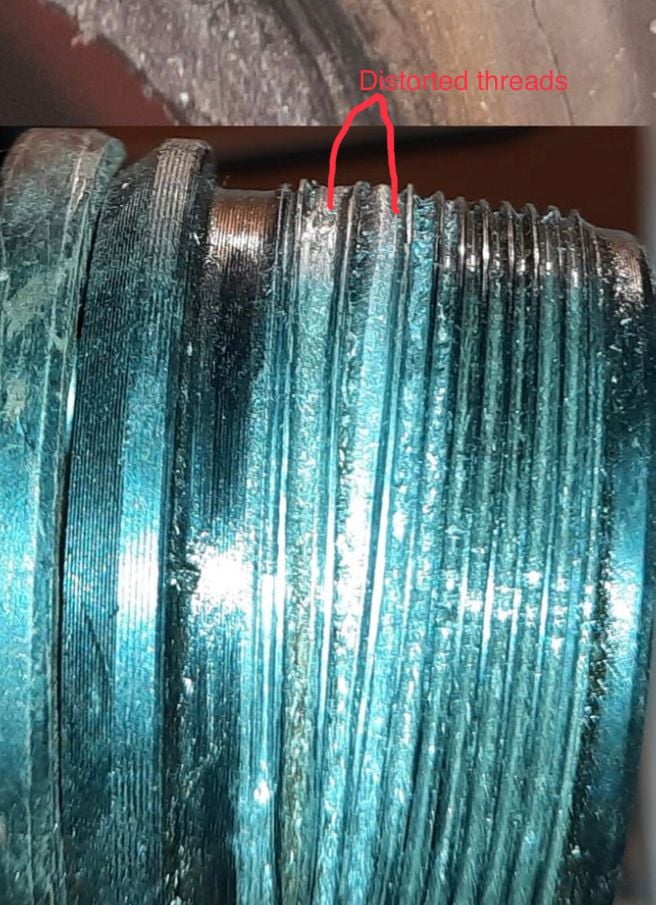

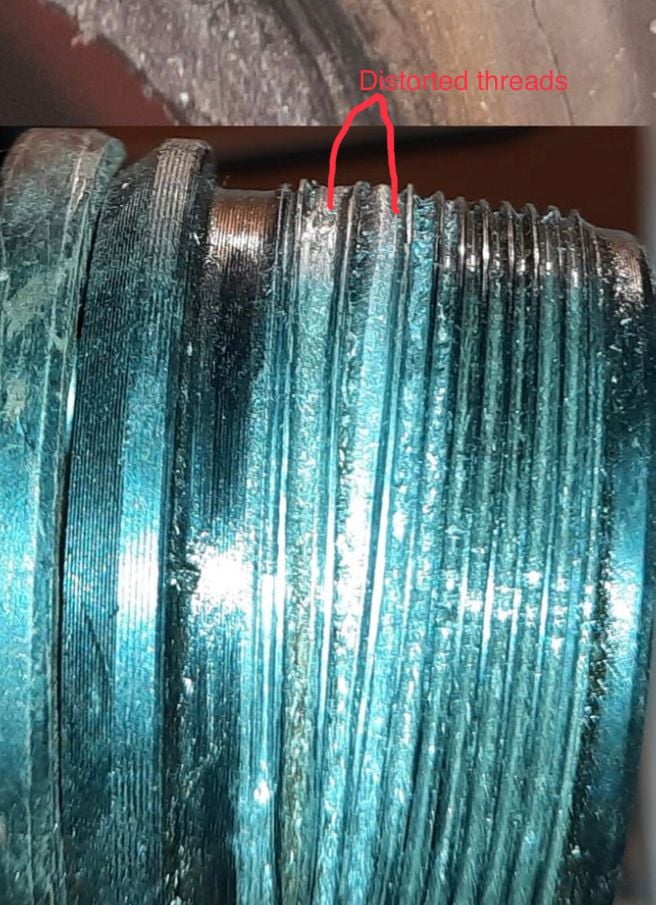

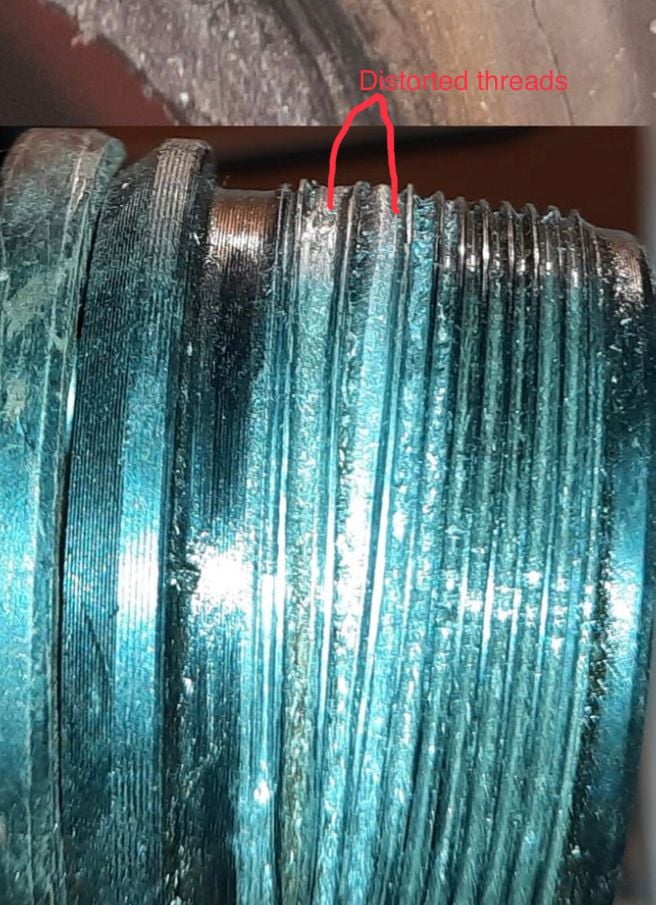

Older-style bottom bracket cup races in varying states of decay out of aluminum frames.

Old-style bottom brackets (cup, caged balls, spindle, caged balls, cup) have the tendency to warp into the aluminum frames. Before this happens, some cups will crack on the race, this is your best indicator to stop and recommend installing a sealed race bottom bracket.

To get these out, use a wood working clamp to hold the bottom bracket tool firm. With splined cups, use a BBT-2 (or equivalent) with 2 ParkTool chain whips so torque can be evenly applied by 2 individuals, again being held with a wood-working clamp.

#2

Senior Member

Good warning. But you lost me at chain whips, on a bottom bracket? If you are grabbing the BB tool with a long woodworking clamp like you recommend, can't each person just grab one end of that? The other possiblity is clamping the BB tool in a vice, and have two people turning the bike frame.

Likes For Duragrouch:

#3

Senior Member

Join Date: Apr 2016

Posts: 1,262

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 510 Post(s)

Liked 450 Times

in

344 Posts

Good warning. But you lost me at chain whips, on a bottom bracket? If you are grabbing the BB tool with a long woodworking clamp like you recommend, can't each person just grab one end of that? The other possiblity is clamping the BB tool in a vice, and have two people turning the bike frame.

#4

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,102

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4214 Post(s)

Liked 3,891 Times

in

2,322 Posts

Older-style bottom bracket cup races in varying states of decay out of aluminum frames.

Old-style bottom brackets (cup, caged balls, spindle, caged balls, cup) have the tendency to warp into the aluminum frames. I don't think I have seen a BB cup "warp" when installed in any frame of any material. How do you come to this claim? Before this happens, some cups will crack on the race and cups cracking, as the most right hand cup in the photo has done, is from the bearing wear on the cup's ball track not from some bending force this is your best indicator to stop and recommend installing a sealed race bottom bracket which would eliminate the need for someone to do a better bearing adjustment than what that cracked cup's BB had, a BB that has been assembled and adjusted well of any type usually out lives a poorly adjusted BB.

To get these out, use a wood working clamp to hold the bottom bracket tool firm. Or a large "C" clamp or a long bolt through the cups and shell With splined cups, use a BBT-2 (or equivalent) with 2 ParkTool chain whips so torque can be evenly applied by 2 individuals, again being held with a wood-working clamp.

Al is far softer and more galling prone then steel is. The photos shows cups with Al "welded" to their threads due to that galling. Most likely the BBs were assembled with no lube or other insulating stuff (grease, anti seize, Teflon tape) between the shell and the cups. In time galvanic corrosion tries to bind the cup within the Al and the forces during removal tear the Al off the shell's inside threads and keep it "connected" to the steel cups.

This has nothing to do with bearing design and everything to do with quality of assembly and maintenance. Andy

__________________

AndrewRStewart

AndrewRStewart

Likes For Andrew R Stewart:

#5

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,378

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6225 Post(s)

Liked 4,228 Times

in

2,372 Posts

Older-style bottom bracket cup races in varying states of decay out of aluminum frames.

Old-style bottom brackets (cup, caged balls, spindle, caged balls, cup) have the tendency to warp into the aluminum frames. Before this happens, some cups will crack on the race, this is your best indicator to stop and recommend installing a sealed race bottom bracket.

Old-style bottom brackets (cup, caged balls, spindle, caged balls, cup) have the tendency to warp into the aluminum frames. Before this happens, some cups will crack on the race, this is your best indicator to stop and recommend installing a sealed race bottom bracket.

To get these out, use a wood working clamp to hold the bottom bracket tool firm. With splined cups, use a BBT-2 (or equivalent) with 2 ParkTool chain whips so torque can be evenly applied by 2 individuals, again being held with a wood-working clamp.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Likes For cyccommute:

#6

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,378

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6225 Post(s)

Liked 4,228 Times

in

2,372 Posts

One aspect of the more current factory assembled BBs is that they are not intended to be serviced so they are considered disposable by most. For better or worse dependent on how you feel about recycling and reusing your stuff.

Al is far softer and more galling prone then steel is. The photos shows cups with Al "welded" to their threads due to that galling. Most likely the BBs were assembled with no lube or other insulating stuff (grease, anti seize, Teflon tape) between the shell and the cups. In time galvanic corrosion tries to bind the cup within the Al and the forces during removal tear the Al off the shell's inside threads and keep it "connected" to the steel cups.

This has nothing to do with bearing design and everything to do with quality of assembly and maintenance. Andy

Al is far softer and more galling prone then steel is. The photos shows cups with Al "welded" to their threads due to that galling. Most likely the BBs were assembled with no lube or other insulating stuff (grease, anti seize, Teflon tape) between the shell and the cups. In time galvanic corrosion tries to bind the cup within the Al and the forces during removal tear the Al off the shell's inside threads and keep it "connected" to the steel cups.

This has nothing to do with bearing design and everything to do with quality of assembly and maintenance. Andy

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#7

Newbie

Thread Starter

Good warning. But you lost me at chain whips, on a bottom bracket? If you are grabbing the BB tool with a long woodworking clamp like you recommend, can't each person just grab one end of that? The other possiblity is clamping the BB tool in a vice, and have two people turning the bike frame.

Park tool BB spline tools, freewheel tools and cassette lockring tools are compatible with Park Tool chain whip hex ends. Just grab a chain whip when using such tools.

#8

Newbie

Thread Starter

#9

Newbie

Thread Starter

Al is far softer and more galling prone then steel is. The photos shows cups with Al "welded" to their threads due to that galling. Most likely the BBs were assembled with no lube or other insulating stuff (grease, anti seize, Teflon tape) between the shell and the cups.

This has nothing to do with bearing design and everything to do with quality of assembly and maintenance. Andy

This has nothing to do with bearing design and everything to do with quality of assembly and maintenance. Andy

I'm sorry, I just have to say, like my boss who has been doing bikes for 30 years now, you've not paid attention to these cups' condition after removing them. The cups are very clearly a weird shape prior to removing them from the frame, with your finger, you can feel on the lower half of the race is super sunken into the frame from the downward force of pedaling. The whole face of that particular cup was protruding out of the frame at a 5° angle, which is impossible for cross threading. And I've seen this a great deal of times now. Is it any different than dealing with galling? Perhaps not. But the cause of condition is very much not the same.

This is why I keep a small collection of these warped cups on hand, to show people and fellow mechanics what they may be dealing with despite having maintained their BB. The "warning cracks" cup is one off a bike that had just eaten its 2nd set of BB caged bearings since 2021, well-maintained and greased.

#10

Newbie

Thread Starter

I have seen shell-sealed OEM "old style" ones on a high quality early 2000s BMX and an early 2000s Giant hard tail that suffered the same fate due to their aluminum frames, and I doubt they were lower quality cups. It seems like the cups will do this from excessive wear no matter what quality they are, the steel becoming super thin and overworked simply cannot support itself and bends down into the softer aluminum.

#11

Senior Member

Join Date: Apr 2016

Posts: 1,262

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 510 Post(s)

Liked 450 Times

in

344 Posts

PTFE tape - I've used plenty on plumbing fittings, never thought to use it on bbkts, or if I had I'd forgotten. I'll hang a roll above my bench for future trial.

#12

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,378

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6225 Post(s)

Liked 4,228 Times

in

2,372 Posts

Note I'm only 21 and have done bikes for only 3 years now.

I have seen shell-sealed OEM "old style" ones on a high quality early 2000s BMX and an early 2000s Giant hard tail that suffered the same fate due to their aluminum frames, and I doubt they were lower quality cups. It seems like the cups will do this from excessive wear no matter what quality they are, the steel becoming super thin and overworked simply cannot support itself and bends down into the softer aluminum.

I have seen shell-sealed OEM "old style" ones on a high quality early 2000s BMX and an early 2000s Giant hard tail that suffered the same fate due to their aluminum frames, and I doubt they were lower quality cups. It seems like the cups will do this from excessive wear no matter what quality they are, the steel becoming super thin and overworked simply cannot support itself and bends down into the softer aluminum.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#13

Newbie

Thread Starter

You may have seen the threads being pulled out of an aluminum frame but I really doubt you've seen distortion of the threads on the bottom bracket itself like the one on the left side of your picture. I've removed thousands of bottom bracket shells over many decades of working on bike and the steel cup pulling apart is only a recent development. It's due to the "steel" used on extremely cheap bikes being contaminated with metals that shouldn't be there. Most likely aluminum which doesn't alloy with iron. I've seen ball bearings that are ground to dust in only a few hundred miles, spindles that are cracked and pulled apart, and many cups that have pulled apart in the frame. It often feels like the bottom bracket is cross threaded and it takes a lot...A LOT!...of effort to remove them. Oddly, the threads of the aluminum bottom bracket are often fine and a new (better) bottom bracket will thread right in without any issues.

I've never personally pulled thread out of a BB before, nor dealt with one thats suffered the most extreme galvanic corrosion, but a customer recently came-in with a sealed bearing race BB that was seized up really bad in an aluminum Specialized due to galvanic corrosion . They took the brake side out themselves along with the thread, but the drive side still had the shell, cup and outer race. The spline quickly stripped, and we couldn't cut through the outer race despite getting a metal blade onto a Sawzall with Mach Lube. After 5 hours, we gave up, a first in the shop's history.

#14

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,378

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6225 Post(s)

Liked 4,228 Times

in

2,372 Posts

Not sure what type of distortion you're referring to in the first sentence, is it not the same thread distortion pictured on the lower right shell? I dealt with many aluminum bikes with heavily distorted thread in the pandemic when I was buying them for cheap, refurbishing them in my garage and reselling them for good money. Many of these bikes had an incredible amount of mileage on them, yet people were willing to pay hundreds thanks to the like-new feel and 30-day warranty and unquestioned return policy (unless the bike was run-over by a vehicle). Man, I miss those summers.

I've never personally pulled thread out of a BB before, nor dealt with one thats suffered the most extreme galvanic corrosion, but a customer recently came-in with a sealed bearing race BB that was seized up really bad in an aluminum Specialized due to galvanic corrosion . They took the brake side out themselves along with the thread, but the drive side still had the shell, cup and outer race. The spline quickly stripped, and we couldn't cut through the outer race despite getting a metal blade onto a Sawzall with Mach Lube. After 5 hours, we gave up, a first in the shop's history.

If the cup cracks or the metal stretches during removal, it is because of some other cause…not galvanic action.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#15

Newbie

Thread Starter

The threads that are pointed out are distorted due to the metal of the cup being stretched. Steel shouldn’t do that even if galvanized to the aluminum. The aluminum threads will pull out before the cup distorts. The cracks in the cup bearing surface are another clue that it is the cup that is defective…not the aluminum of the frame.

That is different from what you are showing above. If you could have gotten the bottom bracket out, the threads in the frame would have been damaged but the threads on the steel part wouldn’t have been damaged. Galvanic corrosion would have caused the formation of aluminum oxide which has a higher volume than the aluminum metal. It jams the threads in place but nothing happens to the steel part. The aluminum undergoes anodic dissolution and is oxidized but the steel undergoes basically nothing. It is the cathode where reduction (going from an oxide to a unoxidized metal) of the steel would have to happen. That can’t happen so the steel remains untouched. It doesn’t thin nor will it crack because of galvanic action.

If the cup cracks or the metal stretches during removal, it is because of some other cause…not galvanic action.

That is different from what you are showing above. If you could have gotten the bottom bracket out, the threads in the frame would have been damaged but the threads on the steel part wouldn’t have been damaged. Galvanic corrosion would have caused the formation of aluminum oxide which has a higher volume than the aluminum metal. It jams the threads in place but nothing happens to the steel part. The aluminum undergoes anodic dissolution and is oxidized but the steel undergoes basically nothing. It is the cathode where reduction (going from an oxide to a unoxidized metal) of the steel would have to happen. That can’t happen so the steel remains untouched. It doesn’t thin nor will it crack because of galvanic action.

If the cup cracks or the metal stretches during removal, it is because of some other cause…not galvanic action.

While i cant say for sure as to the cracks between the thread, I will say that the steel is definitely stretched prior to their removal. The weird physics of this must suggest these newer cups are a very cheap, malleable metal, and I always find it weird how the thread lines seems to just separate rather than break off from the stretched steel. Kinda like how certain polycarbons will stretch into long, strong strings after having force applied to them for decades at room temperature.

The Steel on that bottom right example is worn down super thin on what was the lower half of the cup. The amount of stretch in the steel is relative to the amount of wear inside the cup. And it's been consistent like that for all of them I've seen, especially with the drive side cups as they aren't adjustable.

Aluminum is known to loose strength after repeated stress cycles. Once the steel cup wears thin, the aluminum below starts taking the load to a smaller and smaller area. Eventually, the metal is so thin and the aluminum is so fatigued that it starts crushing down, pushing the face of the bearing cup outwards. This particular bearing cup had about a 2-4mm gap between the lower part of it's external face to the lip of the bottom bracket. Also, notice how the thread of this particular cup only starts after a few mm in? That's another cause, only ~2 rounds of thread are holding back from this force, so they start pushing out the lower part of the cup face.

The extreme mileage and downward force from pedaling are what we're looking at being the main effects for these cups.

#16

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,378

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6225 Post(s)

Liked 4,228 Times

in

2,372 Posts

Loud and clear on the effects of corrosion.

While i cant say for sure as to the cracks between the thread, I will say that the steel is definitely stretched prior to their removal. The weird physics of this must suggest these newer cups are a very cheap, malleable metal, and I always find it weird how the thread lines seems to just separate rather than break off from the stretched steel. Kinda like how certain polycarbons will stretch into long, strong strings after having force applied to them for decades at room temperature.

While i cant say for sure as to the cracks between the thread, I will say that the steel is definitely stretched prior to their removal. The weird physics of this must suggest these newer cups are a very cheap, malleable metal, and I always find it weird how the thread lines seems to just separate rather than break off from the stretched steel. Kinda like how certain polycarbons will stretch into long, strong strings after having force applied to them for decades at room temperature.

The Steel on that bottom right example is worn down super thin on what was the lower half of the cup. The amount of stretch in the steel is relative to the amount of wear inside the cup. And it's been consistent like that for all of them I've seen, especially with the drive side cups as they aren't adjustable.

Aluminum is known to loose strength after repeated stress cycles. Once the steel cup wears thin, the aluminum below starts taking the load to a smaller and smaller area. Eventually, the metal is so thin and the aluminum is so fatigued that it starts crushing down, pushing the face of the bearing cup outwards. This particular bearing cup had about a 2-4mm gap between the lower part of it's external face to the lip of the bottom bracket. Also, notice how the thread of this particular cup only starts after a few mm in? That's another cause, only ~2 rounds of thread are holding back from this force, so they start pushing out the lower part of the cup face.

The extreme mileage and downward force from pedaling are what we're looking at being the main effects for these cups.

The extreme mileage and downward force from pedaling are what we're looking at being the main effects for these cups.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#17

Newbie

Thread Starter

.

Again, I have only seen this kind of damage to newer bottom brackets on cheap department store bikes. I’ve used these kinds of cups extensively on bicycle through the 80s and 90s. Many of them were very high mileage bicycles and I’ve never seen any of those bottom brackets crack or pull the threads out. I’ve also remove lots and lots and lots of bottom brackets from bikes of that era and never seen the kind of damage you are detailing. Those bottom brackets were made of much better metal…even the ones on bikes that were of fairly low levels of quality. It’s not been a problem except on bikes from the 2010s and later.

Again, I have only seen this kind of damage to newer bottom brackets on cheap department store bikes. I’ve used these kinds of cups extensively on bicycle through the 80s and 90s. Many of them were very high mileage bicycles and I’ve never seen any of those bottom brackets crack or pull the threads out. I’ve also remove lots and lots and lots of bottom brackets from bikes of that era and never seen the kind of damage you are detailing. Those bottom brackets were made of much better metal…even the ones on bikes that were of fairly low levels of quality. It’s not been a problem except on bikes from the 2010s and later.

#18

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,102

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4214 Post(s)

Liked 3,891 Times

in

2,322 Posts

A few comments- I should have been more specific WRT galling and galvanic corrosion and how they might relate to BB cups and damage. galvanic corrosion will tend to freeze the cup in place and make removal hard. I probably should have left this out but I believe I've removed cups from Al shells that were really tight and showed all the signs of corrosion bonding.

But this isn't what causes cups to crack and fail (gosh, sounds like a segway to cannondale ). What drives steel loose ball cup cracking, IMO, is work hardening from way too tightly adjusted bearings. Do poor grades of steel contribute? Sure, and I don't disagree at all with the cheapening up of material grades for many bike parts in general (and I've spoken about this for decades but more about cogs and rings). But I've seen "quality" cups suffer too. As the cups are flowed thinner (not abraded) and the hardness increases in time they can crack at a thread root. The outer face of the cup distorts off angle but most of the threaded skirt remains in place. The result is that some threads look stretched because they are.

). What drives steel loose ball cup cracking, IMO, is work hardening from way too tightly adjusted bearings. Do poor grades of steel contribute? Sure, and I don't disagree at all with the cheapening up of material grades for many bike parts in general (and I've spoken about this for decades but more about cogs and rings). But I've seen "quality" cups suffer too. As the cups are flowed thinner (not abraded) and the hardness increases in time they can crack at a thread root. The outer face of the cup distorts off angle but most of the threaded skirt remains in place. The result is that some threads look stretched because they are.

The photo'd cups have what certainly looks to be Al jammed into many of their threads, or at least to my eyes. How does this Al stick to the steel? I suggest by galling during the cup's removal. That a deformed cup that has been used far past it's life might also have some "jamming" happen within the shell's threads and that shell be of a softer metal that has a nature to be able to gall just seem to go together.

But what do I know? I can't see the cup's insides or the shells that they came out of. Or for that matter, the axles that were in these BBs. IME it is the axle that classically has worn/pitted first. Andy

But this isn't what causes cups to crack and fail (gosh, sounds like a segway to cannondale

). What drives steel loose ball cup cracking, IMO, is work hardening from way too tightly adjusted bearings. Do poor grades of steel contribute? Sure, and I don't disagree at all with the cheapening up of material grades for many bike parts in general (and I've spoken about this for decades but more about cogs and rings). But I've seen "quality" cups suffer too. As the cups are flowed thinner (not abraded) and the hardness increases in time they can crack at a thread root. The outer face of the cup distorts off angle but most of the threaded skirt remains in place. The result is that some threads look stretched because they are.

). What drives steel loose ball cup cracking, IMO, is work hardening from way too tightly adjusted bearings. Do poor grades of steel contribute? Sure, and I don't disagree at all with the cheapening up of material grades for many bike parts in general (and I've spoken about this for decades but more about cogs and rings). But I've seen "quality" cups suffer too. As the cups are flowed thinner (not abraded) and the hardness increases in time they can crack at a thread root. The outer face of the cup distorts off angle but most of the threaded skirt remains in place. The result is that some threads look stretched because they are. The photo'd cups have what certainly looks to be Al jammed into many of their threads, or at least to my eyes. How does this Al stick to the steel? I suggest by galling during the cup's removal. That a deformed cup that has been used far past it's life might also have some "jamming" happen within the shell's threads and that shell be of a softer metal that has a nature to be able to gall just seem to go together.

But what do I know? I can't see the cup's insides or the shells that they came out of. Or for that matter, the axles that were in these BBs. IME it is the axle that classically has worn/pitted first. Andy

__________________

AndrewRStewart

AndrewRStewart

Likes For Andrew R Stewart:

#19

Senior Member

Join Date: Apr 2011

Posts: 7,116

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4434 Post(s)

Liked 1,577 Times

in

1,039 Posts

This seems like much ado about nothing. Decent bikes won't have parts like this, and the ones that do just need those parts replaced when they wear out - which, given the mileage most Huffy's get - is mostly never.

The BBs are cheap, the frames still useful. The worst galvanic thread damage I've seen left the threads still usable.

This is interesting, but not necessarily relevant.

The BBs are cheap, the frames still useful. The worst galvanic thread damage I've seen left the threads still usable.

This is interesting, but not necessarily relevant.

#20

Senior Member

Westley: I mean, if we only had a wheelbarrow, that would be something.

Inigo Montoya: Where we did we put that wheelbarrow the albino had?

Fezzik: Over the albino, I think.

Westley: Well, why didn't you list that among our assets in the first place?

#21

Senior Member

Join Date: May 2010

Location: Bastrop Texas

Posts: 4,499

Bikes: Univega, Peu P6, Peu PR-10, Ted Williams, Peu UO-8, Peu UO-18 Mixte, Peu Dolomites

Mentioned: 13 Post(s)

Tagged: 0 Thread(s)

Quoted: 977 Post(s)

Liked 1,638 Times

in

1,052 Posts

I see this happening to so many things now days...

__________________

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

#22

Newbie

Thread Starter

This seems like much ado about nothing. Decent bikes won't have parts like this, and the ones that do just need those parts replaced when they wear out - which, given the mileage most Huffy's get - is mostly never.

The BBs are cheap, the frames still useful. The worst galvanic thread damage I've seen left the threads still usable.

This is interesting, but not necessarily relevant.

The BBs are cheap, the frames still useful. The worst galvanic thread damage I've seen left the threads still usable.

This is interesting, but not necessarily relevant.

Above all, this should be a wake-up call that we should stop repacking this stuff.

#23

Senior Member

Join Date: Apr 2011

Posts: 7,116

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4434 Post(s)

Liked 1,577 Times

in

1,039 Posts

I largely disagree, when I was more novice 3 years ago this would have been extremely helpful knowledge to go by. I hope others can find this info instead of having to struggle with understanding how a BB could be so seized without being corroded at all, along with how to approach such BBs. Many cheap bicycles get lots of work done on them all the time in thousands of shops worldwide, some go through multiple sealed cartridge BBs before they retire.

Above all, this should be a wake-up call that we should stop repacking this stuff.

Above all, this should be a wake-up call that we should stop repacking this stuff.

And I disagree that the cups are 'bending down into the aluminum frame'. The cups engage both the threads and the end of the BB shell - which is why they are faced. So the cup in the photos was either visibly falling out of the frame, and causing the crank to clunk around, or the threads came apart when the cup was removed.

#24

Senior Member

I largely disagree, when I was more novice 3 years ago this would have been extremely helpful knowledge to go by. I hope others can find this info instead of having to struggle with understanding how a BB could be so seized without being corroded at all, along with how to approach such BBs. Many cheap bicycles get lots of work done on them all the time in thousands of shops worldwide, some go through multiple sealed cartridge BBs before they retire.

Above all, this should be a wake-up call that we should stop repacking this stuff.

Above all, this should be a wake-up call that we should stop repacking this stuff.

- Just like 7 and 8 speed chains, which should be more durable because wider than 10/11/12 speed, they are now less durable because the former has poor material, the chainmakers are putting their best steels and surfact finishes into the latter. (See results in Zero Friction Cycling, chain tests.) So my implication is, cups and spindles now may be of worse quality than in the past, because cartridges have taken over 1st world bikes.

- Some have said the bearings were too tight; If spinning the spindle with fingers feels notchy, yes. But less than that, no, proper preload is critical for bearing durability. With any slack, load at a given time goes into 2 or 3 bearing balls on each side. With proper preload, that increases to almost half or 180 degrees of bearing balls on each side, greatly reducing peak bearing loads.

- Seals matter; Lots of cheap cone and cup BBs have no seals, easy for water and grit to get in there, and yeah, even good cups will abrade quickly under those conditions.

- Threaded cups are still better than stamped, pressed in cups for ashtabula (1-piece) cranks, those are thin enough and low strength enough to fracture when a kid doesn't lay the bike down gently but just drops it, the pedal hitting concrete hard enough to do that.

- Like my dad said with regard to the value of slide rules and the knowledge to use them after a nuclear war, if the world goes to cartridge bearings, we're going to be in tough shape in that circumstance. Like people who don't know how to sharpen a knife. Or know their knots.

Last edited by Duragrouch; 03-30-24 at 09:45 PM.

#25

Newbie

Thread Starter

- Like my dad said with regard to the value of slide rules and the knowledge to use them after a nuclear war, if the world goes to cartridge bearings, we're going to be in tough shape in that circumstance. Like people who don't know how to sharpen a knife. Or know their knots.