Locking up a freehub

#1

Newbie

Thread Starter

Join Date: Mar 2024

Posts: 21

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 15 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Locking up a freehub

I know it‘s an occasional occurrence on the Fixed Gear Forum to have a fix-curious asking for the best way to lock his road freehub to make a fixed gear wheel, and I know many of you have "mixed feelings" about it.

In my situation, I have a Christiania Bikes cargo bike with front disk brakes and rear coaster brake (nexus 7 speed), and I want to put a mid drive motor on it. My issue is that almost no mid motors fit on this bike, and even less with a coaster brake option (but yes, coaster brake versions of mid drive motors already do exist, and if there‘s a torque sensor and no throttle, it shouldn‘t be an issue).

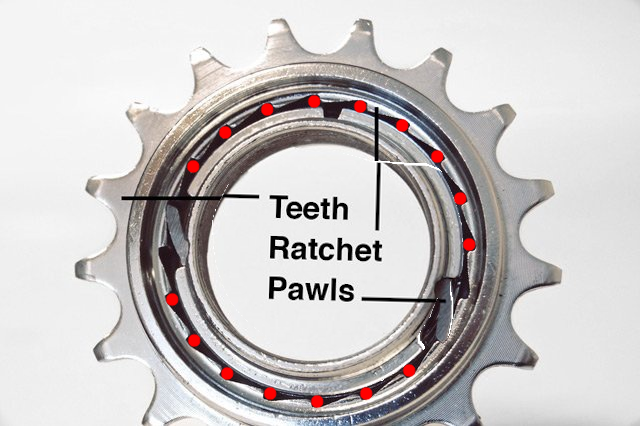

I want to keep the IGH as is, and try to modify the mid drive motor to be able to back pedal to activate the rear coaster brake. The freewheel in the cheap chinese mid drive motor I‘m thinking of is a basic 3 pawls freehub like this :

I don’t think of welding/brazing it for now, not only do I have no confidence in my welding skill, but there‘s quite a lot of stuff around I‘m afraid I would damage.

I was considering sourcing another identical freewheel (asking the manufacturer for a replacement part), flipping it and adding it in place of the bearing that is just in front

Although I still find this solution elegant, it would have been quite a headache fitting the other freewheel (bearing not quite the same outer diameter) and the supplementary keyways on the shaft. Plus, a freewheel does not hold the shaft the way a bearing does... even if this shaft only has torque applied to it (it‘s not the pedal spindle).

I am considering pouring epoxy and/or jamming the pawls.

At first, the most natural way to jam the paws seems to wedge something underneath them, and I guess if it‘s made well it should be fine. I‘ve found instances of people doing that in this forum here and there

But I would not feel 100% confident to, essentially, replace the spring of a system designed to slip with a "very strong spring" and call it locked. After a while, if the wedge/pawl begins to wear, and slips a little, it will only get worse and worse.

I feel like jamming the pawl with a wedge in front of the pawl like this is more robust :

Although I realize it is essentially the same thing (and that both can be done at the same time), I feel like this method is more likely to jam itself further, the further the freewheel tries to slip. Am I crazy?

Anyway, wedging both sides of the pawl with half grinded pawls for exemple, then pouring epoxy should be safe enough?

Otherwise I guess the safer way is to replace the freewheel with a press fit custom keyed bushing thingie? I hope I don‘t have to procure that, and extract the existing freewheel...

What do you suggest to lock this freewheel?

P.S. : Is it possible to get permission to post pictures at some point? Not a native english speaker here, I don‘t think I can clearly describe how I want to jam the freewheel pawls without a picture/drawing.

In my situation, I have a Christiania Bikes cargo bike with front disk brakes and rear coaster brake (nexus 7 speed), and I want to put a mid drive motor on it. My issue is that almost no mid motors fit on this bike, and even less with a coaster brake option (but yes, coaster brake versions of mid drive motors already do exist, and if there‘s a torque sensor and no throttle, it shouldn‘t be an issue).

I want to keep the IGH as is, and try to modify the mid drive motor to be able to back pedal to activate the rear coaster brake. The freewheel in the cheap chinese mid drive motor I‘m thinking of is a basic 3 pawls freehub like this :

I don’t think of welding/brazing it for now, not only do I have no confidence in my welding skill, but there‘s quite a lot of stuff around I‘m afraid I would damage.

I was considering sourcing another identical freewheel (asking the manufacturer for a replacement part), flipping it and adding it in place of the bearing that is just in front

Although I still find this solution elegant, it would have been quite a headache fitting the other freewheel (bearing not quite the same outer diameter) and the supplementary keyways on the shaft. Plus, a freewheel does not hold the shaft the way a bearing does... even if this shaft only has torque applied to it (it‘s not the pedal spindle).

I am considering pouring epoxy and/or jamming the pawls.

At first, the most natural way to jam the paws seems to wedge something underneath them, and I guess if it‘s made well it should be fine. I‘ve found instances of people doing that in this forum here and there

But I would not feel 100% confident to, essentially, replace the spring of a system designed to slip with a "very strong spring" and call it locked. After a while, if the wedge/pawl begins to wear, and slips a little, it will only get worse and worse.

I feel like jamming the pawl with a wedge in front of the pawl like this is more robust :

Although I realize it is essentially the same thing (and that both can be done at the same time), I feel like this method is more likely to jam itself further, the further the freewheel tries to slip. Am I crazy?

Anyway, wedging both sides of the pawl with half grinded pawls for exemple, then pouring epoxy should be safe enough?

Otherwise I guess the safer way is to replace the freewheel with a press fit custom keyed bushing thingie? I hope I don‘t have to procure that, and extract the existing freewheel...

What do you suggest to lock this freewheel?

P.S. : Is it possible to get permission to post pictures at some point? Not a native english speaker here, I don‘t think I can clearly describe how I want to jam the freewheel pawls without a picture/drawing.

Last edited by Jean Daspry; 03-22-24 at 08:47 AM.

#2

Senior Member

If I recall correctly, new members are limited to 5 posts daily until they have 10 total posts. After that, I believe you'll be able to use PMs/post photos/post URLs.

This is an anti-spam measure, and appears to be fairly effective.

You can, however, upload photos to a personal album now. Afterwards, if you post that fact it's very likely someone will give a "pic assist" and post the photos on your behalf.

#3

I'm good to go!

Join Date: Jul 2017

Location: Mississippi

Posts: 14,992

Bikes: Tarmac Disc Comp Di2 - 2020

Mentioned: 51 Post(s)

Tagged: 0 Thread(s)

Quoted: 6196 Post(s)

Liked 4,810 Times

in

3,318 Posts

I like the epoxy idea. Or just weld it up. Certainly nothing inside the freewheel is going to be doing anything if you want it locked up.

But all this seems like a bad idea. If that freewheel was put on there by the bikes manufacturer, there is a reason they wanted it to be there.

Being able to post pictures and links will automatically come after you have ten posts. In the meantime you could just upload them to the Gallery here on BF and tell us they are there.

Welcome to BF.

But all this seems like a bad idea. If that freewheel was put on there by the bikes manufacturer, there is a reason they wanted it to be there.

Being able to post pictures and links will automatically come after you have ten posts. In the meantime you could just upload them to the Gallery here on BF and tell us they are there.

Welcome to BF.

#5

I'm good to go!

Join Date: Jul 2017

Location: Mississippi

Posts: 14,992

Bikes: Tarmac Disc Comp Di2 - 2020

Mentioned: 51 Post(s)

Tagged: 0 Thread(s)

Quoted: 6196 Post(s)

Liked 4,810 Times

in

3,318 Posts

Here is a link to the gallery and one of the pic's...

No response needed from the OP. You only get five posts a day till your 10 post are made. So use replies wisely.

https://www.bikeforums.net/g/album/33084003

No response needed from the OP. You only get five posts a day till your 10 post are made. So use replies wisely.

https://www.bikeforums.net/g/album/33084003

#6

Newbie

Thread Starter

Join Date: Mar 2024

Posts: 21

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 15 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

It is very important when using throttle command or for motors that have difficulty knowing exactly when you want pedal assist and when you don‘t. It should be fine in my case.

The same manufacturer had made a coaster brake compatible version of a previous motor just by removing the throttle connector and replacing the chainring fixation ring (big flat aluminum disk on the picture) with one without freewheel.

Thank you for posting my Gallery and picture.

Last edited by Jean Daspry; 03-19-24 at 11:03 AM.

Likes For Jean Daspry:

#8

Senior Member

Join Date: Apr 2016

Posts: 1,235

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 500 Post(s)

Liked 435 Times

in

334 Posts

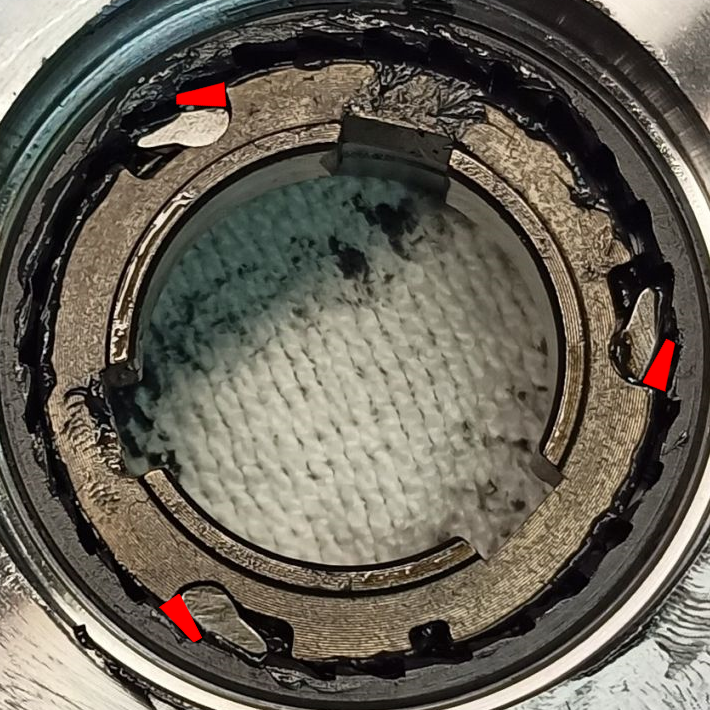

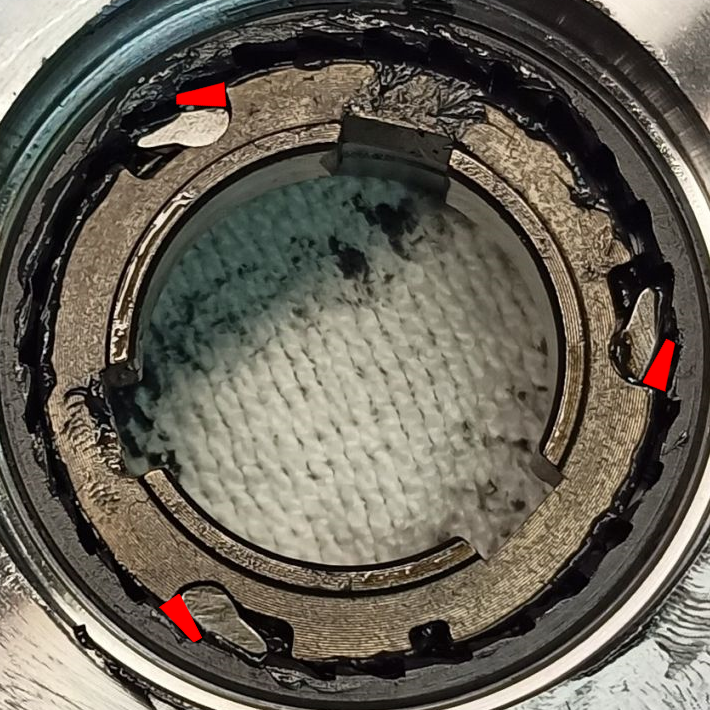

Another idea to lock the freewheel, is to hammer nails all around, suggested by Kontact on another thread :

#9

Newbie

Thread Starter

Join Date: Mar 2024

Posts: 21

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 15 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Or jam in some ball bearings if the gaps are slightly smaller than a common ball size. I just wouldn't want my braking to depend on this cobbled together arrangement, coaster brakes are dodgy enough already, although the back brake isn't very useful anyway no matter how good it is.

#10

Senior Member

Join Date: May 2010

Location: Bastrop Texas

Posts: 4,481

Bikes: Univega, Peu P6, Peu PR-10, Ted Williams, Peu UO-8, Peu UO-18 Mixte, Peu Dolomites

Mentioned: 13 Post(s)

Tagged: 0 Thread(s)

Quoted: 967 Post(s)

Liked 1,630 Times

in

1,046 Posts

I heard of a guy years ago that used a Hot Glue Gun. He hot glued some copper wire into the space to jam the pawls. About a year latter he removed the glue by boiling the freewheel in water.

I guess it really does not take much to jam those pawls...

I guess it really does not take much to jam those pawls...

__________________

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

Likes For zandoval:

#11

Newbie

Thread Starter

Join Date: Mar 2024

Posts: 21

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 15 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

The hot glue gun, I can understand if you don‘t want it to be permanent... The copper wire to jam the pawls, that‘s a whole new level... but it‘s good to know. It was some good quality solid-core copper wire, I hope? Do you think he used it to skid stop a lot? I hope he saved the freewheel broth for later.

#13

Newbie

Thread Starter

Join Date: Mar 2024

Posts: 21

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 15 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Yeah, welding it would probably work, but again, I don‘t trust my welds, plus I would have to extract the freewheel to do it in order to be sure not to mangle the sprag clutch next to it (and I would need to wedge the freewheel before welding, because as you can see it‘s kinda hard to make sure it‘s centered when dismantled). And yes, it’s not very reversible.

I’m perplexed, as most of you guys seem sketched out by the idea, but none steer me towards the only 100% safe option : the custom bushing.

It was not my preferred option as I hoped to find a safe enough option by jamming the freewheel, but entirely replacing the freewheel with a "tapered bushing" of sorts, or an aluminum washer with custom keyways is still an option, or am I missing something?

I’m perplexed, as most of you guys seem sketched out by the idea, but none steer me towards the only 100% safe option : the custom bushing.

It was not my preferred option as I hoped to find a safe enough option by jamming the freewheel, but entirely replacing the freewheel with a "tapered bushing" of sorts, or an aluminum washer with custom keyways is still an option, or am I missing something?

#14

Clark W. Griswold

Join Date: Mar 2014

Location: ,location, location

Posts: 13,525

Bikes: Foundry Chilkoot Ti W/Ultegra Di2, Salsa Timberjack Ti, Cinelli Mash Work RandoCross Fun Time Machine, 1x9 XT Parts Hybrid, Co-Motion Cascadia, Specialized Langster, Phil Wood Apple VeloXS Frame (w/DA 7400), R+M Supercharger2 Rohloff, Habanero Ti 26

Mentioned: 54 Post(s)

Tagged: 0 Thread(s)

Quoted: 4357 Post(s)

Liked 3,995 Times

in

2,666 Posts

Yeah, welding it would probably work, but again, I don‘t trust my welds, plus I would have to extract the freewheel to do it in order to be sure not to mangle the sprag clutch next to it (and I would need to wedge the freewheel before welding, because as you can see it‘s kinda hard to make sure it‘s centered when dismantled). And yes, it’s not very reversible.

I’m perplexed, as most of you guys seem sketched out by the idea, but none steer me towards the only 100% safe option : the custom bushing.

It was not my preferred option as I hoped to find a safe enough option by jamming the freewheel, but entirely replacing the freewheel with a "tapered bushing" of sorts, or an aluminum washer with custom keyways is still an option, or am I missing something?

I’m perplexed, as most of you guys seem sketched out by the idea, but none steer me towards the only 100% safe option : the custom bushing.

It was not my preferred option as I hoped to find a safe enough option by jamming the freewheel, but entirely replacing the freewheel with a "tapered bushing" of sorts, or an aluminum washer with custom keyways is still an option, or am I missing something?

When someone has an idea that is not a good idea it is unlikely those people who understand that it is a bad idea are going to say yeah go ahead with that idea or here is the same idea but in a slightly different way.

You could reach out to the manufacturer and give them your idea and they can say probably the same thing as everyone else has been saying. Or you can keep shopping around for someone to parrot your bad idea and you can get that echo chamber you seek. I get it "yes men" are kind of nice to have around when everything is agreeable it feels good but having a challenge is better because it gives you a chance to think and reflect and maybe makes you tweak your idea to improve it or realize you should move on and not waste too much time and breathe on it and it may also challenge someone else as well. My business partner and I had some arguments about certain things and it I think made us both stronger and have some alternative ideas to make it work. It wasn't perfect but it did help us move forward in a better way then just let's do something not so good just to do it.

#15

Newbie

Thread Starter

Join Date: Mar 2024

Posts: 21

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 15 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

By the way the sprag clutch had rare instances of failing both ways, if not properly cared for, so replacing it with a locking bushing did probably make the mid drive safer.

The coaster brake version of this motor though, seems to not yet be in production and they did not give me a date for it. They must be focused on ramping up and polishing the base model and only doing the coaster brake version when/if there is sufficient demand for it.

So yes, unless you have evidence showing otherwise, replacing the freewheel with a bushing would be a 100% safe option.

Not easy to procure though. And not the only option.

Or you can keep shopping around for someone to parrot your bad idea and you can get that echo chamber you seek. I get it "yes men" are kind of nice to have around when everything is agreeable it feels good but having a challenge is better because it gives you a chance to think and reflect and maybe makes you tweak your idea to improve it or realize you should move on and not waste too much time and breathe on it and it may also challenge someone else as well.

If you don‘t like echo chambers, an open mind, a thirst for knowledge, cross-cultural learning, questioning your own beliefs, challenging one-sided narratives and your confirmation bias should maybe be your priority.

I can only imagine, yes.

#16

Clark W. Griswold

Join Date: Mar 2014

Location: ,location, location

Posts: 13,525

Bikes: Foundry Chilkoot Ti W/Ultegra Di2, Salsa Timberjack Ti, Cinelli Mash Work RandoCross Fun Time Machine, 1x9 XT Parts Hybrid, Co-Motion Cascadia, Specialized Langster, Phil Wood Apple VeloXS Frame (w/DA 7400), R+M Supercharger2 Rohloff, Habanero Ti 26

Mentioned: 54 Post(s)

Tagged: 0 Thread(s)

Quoted: 4357 Post(s)

Liked 3,995 Times

in

2,666 Posts

You are totally missing my point. I do know that the idea seems sketchy, as I addressed in the first sentence of this thread. However, I‘m perplexed that the safer option is not the one most often recommended, if safety is the priority concern.

What makes you think it was not designed to be modified in that way? As we already glimpsed on this thread, you don‘t seem to have the knowledge or experience to be speaking for “real actual mechanics” about coaster brake and mid drive motors designs.

I already did reach out to the manufacturer, and that is where the bushing idea comes from, as it is one of the ways they said they already used on the previous model for the exact same coaster brake conversion, except it was a sprag clutch being replaced, not a pawl-ratchet freewheel :

By the way the sprag clutch had rare instances of failing both ways, if not properly cared for, so replacing it with a locking bushing did probably make the mid drive safer.

The coaster brake version of this motor though, seems to not yet be in production and they did not give me a date for it. They must be focused on ramping up and polishing the base model and only doing the coaster brake version when/if there is sufficient demand for it.

So yes, unless you have evidence showing otherwise, replacing the freewheel with a bushing would be a 100% safe option.

Not easy to procure though. And not the only option.

You‘re a funny man, blabbering about “yes men” and echo chambers, without at any point bringing any valid argument or constructive criticism in the conversation. I respect your opinion and it‘s good to have one more, but the more you show your lack of knowledge on the subject, the less it weighs.

If you don‘t like echo chambers, an open mind, a thirst for knowledge, cross-cultural learning, questioning your own beliefs, challenging one-sided narratives and your confirmation bias should maybe be your priority.

I can only imagine, yes.

What makes you think it was not designed to be modified in that way? As we already glimpsed on this thread, you don‘t seem to have the knowledge or experience to be speaking for “real actual mechanics” about coaster brake and mid drive motors designs.

I already did reach out to the manufacturer, and that is where the bushing idea comes from, as it is one of the ways they said they already used on the previous model for the exact same coaster brake conversion, except it was a sprag clutch being replaced, not a pawl-ratchet freewheel :

By the way the sprag clutch had rare instances of failing both ways, if not properly cared for, so replacing it with a locking bushing did probably make the mid drive safer.

The coaster brake version of this motor though, seems to not yet be in production and they did not give me a date for it. They must be focused on ramping up and polishing the base model and only doing the coaster brake version when/if there is sufficient demand for it.

So yes, unless you have evidence showing otherwise, replacing the freewheel with a bushing would be a 100% safe option.

Not easy to procure though. And not the only option.

You‘re a funny man, blabbering about “yes men” and echo chambers, without at any point bringing any valid argument or constructive criticism in the conversation. I respect your opinion and it‘s good to have one more, but the more you show your lack of knowledge on the subject, the less it weighs.

If you don‘t like echo chambers, an open mind, a thirst for knowledge, cross-cultural learning, questioning your own beliefs, challenging one-sided narratives and your confirmation bias should maybe be your priority.

I can only imagine, yes.

In terms of that other thread yes Bosch makes something for coaster brakes, it is something newer that I had not seen and does not really apply here because you aren't running a Bosch equipped bike and cannot get a Bosch system for that bike as they don't make aftermarket kits. However yes generally coaster brakes and e-bikes are extremely uncommon and many of the examples you gave save for one didn't have a coaster brake. However again those were Bosch not a whatever random online motor this is.

What makes me think it wasn't designed to be modified, because it does not come in that configuration and the manufacturer more than likely does not have a fix for it. You say they might be working on it so I guess that would be waiting for them to release that or working with them on it but if the manufacturer had a safe way to do it, you would not be here.

You clearly missed my point about yes men and echo chambers or don't understand what they are. You are wanting someone to tell you what you want to hear that is why I wrote that. You were wondering why people aren't suggesting you do it and "safe" ways to do it. You want someone to say your idea is great modify the motor and here is how to do and clearly people have not done that but you want those people reinforcing what you want to do. Hence yes men.

#17

Senior Member

Join Date: Jul 2006

Location: San Jose (Willow Glen) Ca

Posts: 9,847

Bikes: Kirk Custom JK Special, '84 Team Miyata,(dura ace old school) 80?? SR Semi-Pro 600 Arabesque

Mentioned: 106 Post(s)

Tagged: 0 Thread(s)

Quoted: 2338 Post(s)

Liked 2,827 Times

in

1,543 Posts

OP has bike that was not designed for a mid drive and wants to keep sub par coaster braking by modifying a mid drive not designed to use coaster brake to use one, he can sort of fit to the bike

sure it might be able to be done but in any event

warranty on the mid drive is gone

breaking subpar, especially for added power from an edrive

reliability reduced

added failure mode

all in all not a good or wise idea. there is a line between being creative/innovative and just dumb

sure it might be able to be done but in any event

warranty on the mid drive is gone

breaking subpar, especially for added power from an edrive

reliability reduced

added failure mode

all in all not a good or wise idea. there is a line between being creative/innovative and just dumb

__________________

Life is too short not to ride the best bike you have, as much as you can

(looking for Torpado Super light frame/fork or for Raleigh International frame fork 58cm)

Life is too short not to ride the best bike you have, as much as you can

(looking for Torpado Super light frame/fork or for Raleigh International frame fork 58cm)

Likes For squirtdad:

#18

Senior Member

Not at all familiar with the system you are modifying. But in general, trying to lock the hub by wedging the pawls permanently outward, or jamming pins or ball bearings in all the other ratchet teeth, is a bad idea; All increase the radial loads, pushing inward on the inner section, and outward on the outer section, beyond design loads. The jammed pawls, only two but running backwards will exert great outward radial force due to the wedge (back of tooth) profile. The pins or balls, not as much individually but all summed together it's a lot of radial force, which will may stretch or fatigue in time, the outer ring, and fail at the worst time, and the inner threaded portion may lock permanently on the hub. I do not know the design loads and margins. I just know you would be exceeding them.

Regarding welding, all the parts above are hardened steel, not typically weldable, and it can anneal (soften) the steel in the heat-affected zone, so quite probably will fail.

Brazing it all together might possibly be accomplished at temperatures that will not affect the hardness. But I don't know the bond shear strength of brazing, nor shear strength of the braze material, but I'll bet both are way below hardened steel.

Regarding welding, all the parts above are hardened steel, not typically weldable, and it can anneal (soften) the steel in the heat-affected zone, so quite probably will fail.

Brazing it all together might possibly be accomplished at temperatures that will not affect the hardness. But I don't know the bond shear strength of brazing, nor shear strength of the braze material, but I'll bet both are way below hardened steel.

Last edited by Duragrouch; 03-30-24 at 02:03 AM.

#19

Senior Member

Join Date: Apr 2016

Posts: 1,235

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 500 Post(s)

Liked 435 Times

in

334 Posts

Did anyone suggest filling it with solder? Maybe a low melting alloy like bismuth tin. That wouldn't be ideal (low shear strength, possibly sufficient) but perhaps another similar.

#20

Newbie

Thread Starter

Join Date: Mar 2024

Posts: 21

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 15 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Not at all familiar with the system you are modifying. But in general, trying to lock the hub by wedging the pawls permanently outward, or jamming pins or ball bearings in all the other ratchet teeth, is a bad idea; All increase the radial loads, pushing inward on the inner section, and outward on the outer section, beyond design loads. The jammed pawls, only two but running backwards will exert great outward radial force due to the wedge (back of tooth) profile. The pins or balls, not as much individually but all summed together it's a lot of radial force, which will may stretch or fatigue in time, the outer ring, and fail at the worst time, and the inner threaded portion may lock permanently on the hub. I do not know the design loads and margins. I just know you would be exceeding them.

Regarding welding, all the parts above are hardened steel, not typically weldable, and it can anneal (soften) the steel in the heat-affected zone, so quite probably will fail.

Brazing it all together might possibly be accomplished at temperatures that will not affect the hardness. But I don't know the bond shear strength of brazing, nor shear strength of the braze material, but I'll bet both are way below hardened steel.

Regarding welding, all the parts above are hardened steel, not typically weldable, and it can anneal (soften) the steel in the heat-affected zone, so quite probably will fail.

Brazing it all together might possibly be accomplished at temperatures that will not affect the hardness. But I don't know the bond shear strength of brazing, nor shear strength of the braze material, but I'll bet both are way below hardened steel.

The radial forces on the inward and outward section will be bigger with the pawls jammed backwards, due to the wedge profile? Can you explain how please, I don‘t quite see it.

Do you know how the forces and fatigue of the needle rollers/balls against the outer ring would compare with those on a roller clutch?

I don‘t have an inner threaded portion though, and locking the hub is the goal, the failing would be for it to unlock.

What do you think about adding an identical, flipped freewheel? Surely the load and margins would stay in spec, then?

By the way, what about replacing the freewheel with a locking keyed bushing? Nobody prefers it over the other options?

Last edited by Jean Daspry; 03-30-24 at 07:42 AM.

#21

Senior Member

Filling it with solder would be under the brazing method, an interesting idea. I've yet to see an example of a brazed freewheel, but some reportedly have done it.

Now that‘s a constructive answer, thank you so much.

The radial forces on the inward and outward section will be bigger with the pawls jammed backwards, due to the wedge profile? Can you explain how please, I don‘t quite see it.

Do you know how the forces and fatigue of the needle rollers/balls against the outer ring would compare with those on a roller clutch?

I don‘t have an inner threaded portion though, and locking the hub is the goal, the failing would be for it to unlock.

What do you think about adding an identical, flipped freewheel? Surely the load and margins would stay in spec, then?

By the way, what about replacing the freewheel with a locking keyed bushing? Nobody prefers it over the other options?

Now that‘s a constructive answer, thank you so much.

The radial forces on the inward and outward section will be bigger with the pawls jammed backwards, due to the wedge profile? Can you explain how please, I don‘t quite see it.

Do you know how the forces and fatigue of the needle rollers/balls against the outer ring would compare with those on a roller clutch?

I don‘t have an inner threaded portion though, and locking the hub is the goal, the failing would be for it to unlock.

What do you think about adding an identical, flipped freewheel? Surely the load and margins would stay in spec, then?

By the way, what about replacing the freewheel with a locking keyed bushing? Nobody prefers it over the other options?

I endeavor to be constructive.

You're right that a roller clutch exerts high radial forces on the assembly, necessary, because when locked, it is relying on friction between smooth metal parts, and it would be designed for those loads. Ratchets do not exert nearly the same radial loads; If you draw a line tangent to the diameter at the pawl pivot points, then join that with the angle of the pawls when locked, and a third line perpindicular to that first tangent line, you have a right triangle which describes the forces involved; Let us say the pawl angle is 30 degrees, probably less, but that's a good worst case, when engaged with the tooth, the "adjacent" side (across from the hypotenuse/pawl-line), is your circumferential driving force, which is (pawl compression load)cos(30 deg) = 0.87 or 87% of the pawl compression load, pretty good. The radial load is the "opposite" side to the 30 degree angle, so (pawl compression load)sin(30 deg) = 0.5 or 50% of the pawl load, so-so, making the pawl locked angle as 20 degrees will cut that down to 34%, better. 10 degree pawls provides 17% radial and 98% drive loads, now we're talking.

With a roller clutch, it's the opposite in concept; A higher wedge angle will exert less radial load, but may slip. A lower wedge angle is more likely to generate sufficient friction to lock, but at the expense of higher outward radial load, so those inner and outer rings need to be stronger and stiffer (two distinctly different properties, by the way) than with a ratchet. That is the advantage of a ratchet, the assembly can be lighter and manage the loads, at the expense of clicking sound when overunning, and needing strong and hard pawls, pivot pins, and teeth, and very durable pawl springs which are tiny but may go through millions of cycles in the life of the hub.

Trying to lock the pawls outward is even worse than a roller clutch; The rollers are solid and hard so difficult to compress; The pawls, at a shallow angle and the ratchet run backwards, the compression force trying to push the pawls in is great; Possibly something solid steel and very hard and high strength metal (like a roller or ball bearing) behind the pawl might stand up to the load, however, a steel ball or pin behind the ratchet will be pushing on the center of the pawl, and the unsupported end of the pawl will probably snap off, as well as the outer ratchet ring, under outward radial loads well above design, may "burst" circumferentially, as its hardness will probably prevent much plastic stretching before ultimate tensile failure.

Two coaxial opposed ratchets could work. However, bike hub ratchets are designed for human drive loads. If you have a motor that exceeds that load, or, under hard braking you exert greater torque on the ratchet than normal human power, it may overload whichever ratchet is handling braking.

Let's see... did I forget any of your questions? I think that will do for now.

Like I said, I don't understand exactly your intended implementation for the locked hub, if I recall, I think you may have said a motor is involved. But I hope the above helps.

Last edited by Duragrouch; 03-31-24 at 03:06 AM.

#22

Old fart

Join Date: Nov 2004

Location: Appleton WI

Posts: 24,790

Bikes: Several, mostly not name brands.

Mentioned: 153 Post(s)

Tagged: 0 Thread(s)

Quoted: 3590 Post(s)

Liked 3,401 Times

in

1,935 Posts

I see no point in doing so. It would result in the same problem as threading a track sprocket directly onto a freewheel hub: it will unthread itself if/when you resist the pedals to control speed.

Likes For JohnDThompson:

#23

I am potato.

Join Date: Jun 2015

Location: Pacific Northwest

Posts: 3,116

Bikes: Only precision built, custom high performance elitist machines of the highest caliber. 🍆

Mentioned: 29 Post(s)

Tagged: 0 Thread(s)

Quoted: 1789 Post(s)

Liked 1,629 Times

in

933 Posts

I agree with JohnDThompson

Being unfamiliar with this ratcheting mechanism or the e-motor this ratcheting mechanism is mounted to the output of...What are the odds that the ratchet drive ring will simply unscrew when reverse forces are applied?

It's gotta be a hardened steel of some sort. They can't possibly machine it in and harden locally, can they? The production process cost would be prohibitive. The ratchet ring has got to be a seperate piece and threaded in.

Tack welding in the drive ring would have to be a requirement contingent upon both being compatible weldable metals.

Failing that, why not machine a solid bushing and press it in to the output gear with a keyway and pin to dummy out the whole ratchet altogether?

Being unfamiliar with this ratcheting mechanism or the e-motor this ratcheting mechanism is mounted to the output of...What are the odds that the ratchet drive ring will simply unscrew when reverse forces are applied?

It's gotta be a hardened steel of some sort. They can't possibly machine it in and harden locally, can they? The production process cost would be prohibitive. The ratchet ring has got to be a seperate piece and threaded in.

Tack welding in the drive ring would have to be a requirement contingent upon both being compatible weldable metals.

Failing that, why not machine a solid bushing and press it in to the output gear with a keyway and pin to dummy out the whole ratchet altogether?

Last edited by base2; 03-31-24 at 09:45 AM.

#24

Senior Member

Join Date: Apr 2016

Posts: 1,235

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 500 Post(s)

Liked 435 Times

in

334 Posts

I was specifically suggesting alloys with particularly low melting point, so less harmful to hardened steel and also more easily removed if it didn't work out. More like creating a cast locking component rather than joining things together with heat.

#25

Senior Member

+10. Didn't occur to me. But I don't know if the OP is doing this with a traditional threaded freewheel, or if a freewheel in a different configuration.