What's this part?

#1

Newbie

Thread Starter

What's this part?

Hi all - been riding my 197? peugeot for several years with the odd repair here and there. Most recently the crank assembly seized up and I had to disassemble, grease and reassemble. Changed the pedals while I was at it. here's the thread: https://www.bikeforums.net/classic-v...-question.html

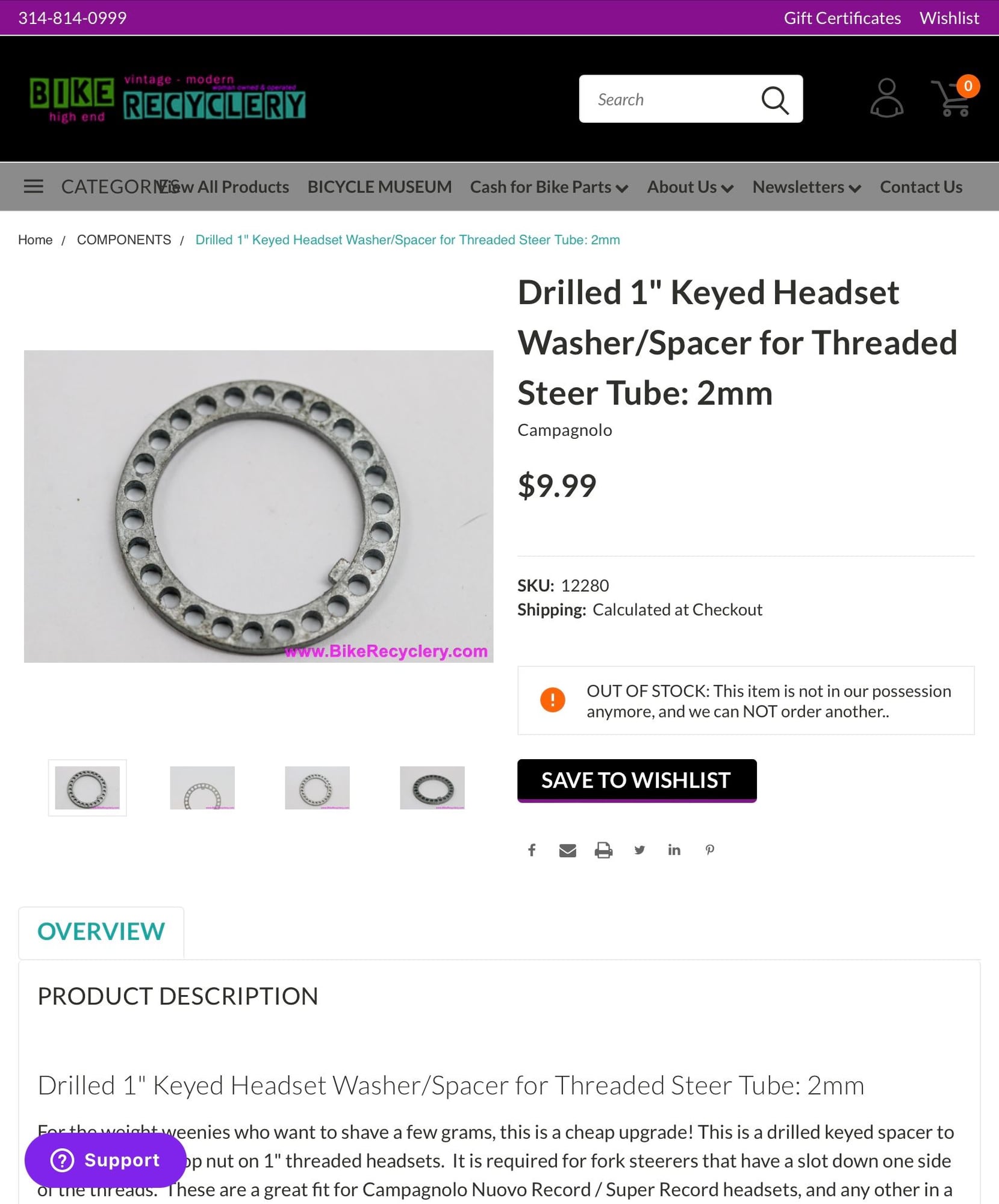

I got hit by a reckless cyclist the other week - ruined the front wheel and bent the front forks beyond repair. The frame was ok. (so were the both of us). I found another vintage Peugeot on Craigslist to part together a full bike. I broke a part in disassembling one of the headsets (don't remember which one now:

This fits right between the washer that holds the front brake cable and the nut that holds the front fork in place. Does anyone know 1. what it's called, and 2. where i could source a replacement? (short of buying a whole noter busted up old bike to steal parts from)

Thanks!

Geoff

I got hit by a reckless cyclist the other week - ruined the front wheel and bent the front forks beyond repair. The frame was ok. (so were the both of us). I found another vintage Peugeot on Craigslist to part together a full bike. I broke a part in disassembling one of the headsets (don't remember which one now:

This fits right between the washer that holds the front brake cable and the nut that holds the front fork in place. Does anyone know 1. what it's called, and 2. where i could source a replacement? (short of buying a whole noter busted up old bike to steal parts from)

Thanks!

Geoff

#2

Senior Member

Join Date: May 2010

Location: Bastrop Texas

Posts: 4,481

Bikes: Univega, Peu P6, Peu PR-10, Ted Williams, Peu UO-8, Peu UO-18 Mixte, Peu Dolomites

Mentioned: 13 Post(s)

Tagged: 0 Thread(s)

Quoted: 967 Post(s)

Liked 1,631 Times

in

1,047 Posts

Gee... I got about four of these that look just like it... Broken in half... Ha

Just get some aluminum headset spacers. The notch and holes are not really that important. The space it occupies is...

Just get some aluminum headset spacers. The notch and holes are not really that important. The space it occupies is...

__________________

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

Likes For zandoval:

#4

Senior Member

Join Date: Dec 2015

Location: Menomonee Falls, WI

Posts: 1,834

Bikes: 1984 Schwinn Supersport, 1988 Trek 400T, 1977 Trek TX900, 1982 Bianchi Champione del Mondo, 1978 Raleigh Supercourse, 1986 Trek 400 Elance, 1991 Waterford PDG OS Paramount, 1971 Schwinn Sports Tourer, 1985 Trek 670

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 604 Post(s)

Liked 1,064 Times

in

535 Posts

It is one of these, a drilled 1” headset spacer, apparently I bought the last one a couple of weeks ago.

Tim

Tim

Likes For tkamd73:

#5

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

If you leave the holy washer out, you'll need to also remove the pin on the screwed race that sticks up into the hole in the washer.

Likes For bulgie:

#6

Senior Member

Join Date: Nov 2015

Posts: 4,489

Mentioned: 102 Post(s)

Tagged: 0 Thread(s)

Quoted: 1641 Post(s)

Likes: 0

Liked 831 Times

in

540 Posts

Cool drillium holes on that thing......but it makes it much more prone to breaking like the one pictured..... I think you could not see those holes anyway; when the headset is installed.....

__________________

72 Line Seeker

83 Davidson Signature

84 Peugeot PSV

84 Peugeot PY10FC

84 Gitane Tour de France.

85 Vitus Plus Carbone 7

86 ALAN Record Carbonio

86 Medici Aerodynamic (Project)

88 Pinarello Montello

89 Bottecchia Professional Chorus SL

95 Trek 5500 OCLV (Project)

72 Line Seeker

83 Davidson Signature

84 Peugeot PSV

84 Peugeot PY10FC

84 Gitane Tour de France.

85 Vitus Plus Carbone 7

86 ALAN Record Carbonio

86 Medici Aerodynamic (Project)

88 Pinarello Montello

89 Bottecchia Professional Chorus SL

95 Trek 5500 OCLV (Project)

#7

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

If you don't want to remove the pin on the screwed race, like out of a conservationist, stewardship impulse, then (1) good on ya, and (2) just drill one hole going that direction in a normal headset washer, for the pin to go up in. Then you have to remove the tongue if it's a tongue washer, or file the hole round if it's a D-shaped hole for a steerer with a flat. The washer with the hole will need to be free to rotate, or you won't be able to adjust the headset. Sorry if I'm belaboring the obvious.

That might be too much work, so I won't judge ya if you just perform a pin-ectomy. These aren't precious artifacts.

AFAIK, the headset in question is a Peugeot proprietary part, maybe even made in-house? Never seen 'em on any other bike brand, except for the badge-engineered brands like Helium that were just Peugeots in other livery. They didn't use the Peugeot headsets in PXes though, not that I saw. PX-10 and it's higher-end cousins always got a brand-name headset like Stronglight.

I think the headset with the "drillium" adjusting washer was used on UO-8 and its lower-end cousins.

That might be too much work, so I won't judge ya if you just perform a pin-ectomy. These aren't precious artifacts.

AFAIK, the headset in question is a Peugeot proprietary part, maybe even made in-house? Never seen 'em on any other bike brand, except for the badge-engineered brands like Helium that were just Peugeots in other livery. They didn't use the Peugeot headsets in PXes though, not that I saw. PX-10 and it's higher-end cousins always got a brand-name headset like Stronglight.

I think the headset with the "drillium" adjusting washer was used on UO-8 and its lower-end cousins.

#8

Senior Member

Join Date: Jan 2004

Location: Madison, WI USA

Posts: 6,157

Mentioned: 50 Post(s)

Tagged: 0 Thread(s)

Quoted: 2363 Post(s)

Liked 1,749 Times

in

1,191 Posts

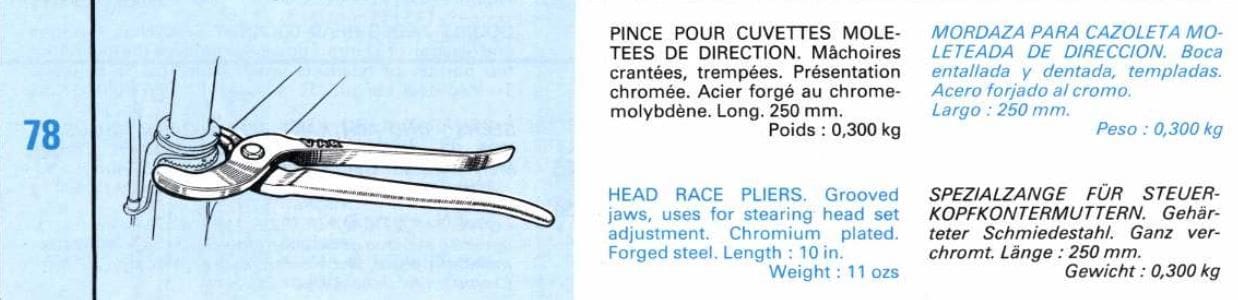

Seems to me the spacer is drilled all the way around in order to accommodate the pin in the threaded race no matter what angle/position it's in when it's properly loaded. And the spacer then ties that position to the steerer via the internal notch that engages the slot on the steerer. This is analogous to the headsets that have the jagged-tooth interface between the threaded race and the spacer, which also has the internal notch. Of course, there are plenty of headsets that rely simply on the pressure between the treaded race and the locknut, via a notched washer, without any such "indexing". I reckon this design and the jagged-tooth design allow for lower torque on the top nut.

Likes For madpogue:

#9

Newbie

Thread Starter

#10

Senior Member

Join Date: Feb 2020

Posts: 2,820

Mentioned: 49 Post(s)

Tagged: 0 Thread(s)

Quoted: 1106 Post(s)

Likes: 0

Liked 1,328 Times

in

784 Posts

That is a supposed locking mechanism so (supposedly) the cone won't move when you tighten the locknut.

It is another bad idea (see fluted seatposts etc) because

a) it doesn't work

b) it limits the precision of cone adjustment - you only have as many positions as holes - almost certainly one will be too tight and the next too loose.

Throw it away, knock off the pin, use a plain spacer if necessary, and prevent the cone from moving by, um, preventing from moving: use TWO spanners.

You can get perfect adjustment, and it won't change.

It is another bad idea (see fluted seatposts etc) because

a) it doesn't work

b) it limits the precision of cone adjustment - you only have as many positions as holes - almost certainly one will be too tight and the next too loose.

Throw it away, knock off the pin, use a plain spacer if necessary, and prevent the cone from moving by, um, preventing from moving: use TWO spanners.

You can get perfect adjustment, and it won't change.

#11

Stop reading my posts!

Join Date: Sep 2004

Posts: 12,584

Mentioned: 90 Post(s)

Tagged: 0 Thread(s)

Quoted: 1444 Post(s)

Liked 1,063 Times

in

788 Posts

I agree it's fussy and prone to break: IIRC it's some zinc-alloy too so even more brittle than if they had used steel.

That said I believe I have a complete HS with that washer (unbroken for now) from a 1950's era Peugeot which I'd sell complete and you could take any/all parts from it that you want. But I don't want to break it up (if it is complete like I remember) just shoot a PM

UPDATE: my "complete but without loose bearing balls" HS is SOLD.

For the trivia buffs this was supposedly circa 1952 and the "perforated washer" was indeed not steel, something like zinc alloy.

The thing I noticed is several of the parts were stamped with a "Peugeot Lion" logo so this was a proprietary part BITD.

That said I believe I have a complete HS with that washer (unbroken for now) from a 1950's era Peugeot which I'd sell complete and you could take any/all parts from it that you want. But I don't want to break it up (if it is complete like I remember) just shoot a PM

UPDATE: my "complete but without loose bearing balls" HS is SOLD.

For the trivia buffs this was supposedly circa 1952 and the "perforated washer" was indeed not steel, something like zinc alloy.

The thing I noticed is several of the parts were stamped with a "Peugeot Lion" logo so this was a proprietary part BITD.

Last edited by unworthy1; 03-23-24 at 08:55 PM.

Likes For unworthy1:

#12

Senior Member

Join Date: Jan 2004

Location: Madison, WI USA

Posts: 6,157

Mentioned: 50 Post(s)

Tagged: 0 Thread(s)

Quoted: 2363 Post(s)

Liked 1,749 Times

in

1,191 Posts

The catch is, a lot of the headsets that use race locking mechanisms like this, and the jagged-tooth style, do not have flats on the threaded race for the preferred two-spanner approach as described above. So if you decommission the locking mechanism, you need some other way to hold the threaded race in position. A strap wrench might do the trick.

Or, at that point, a headset that actually accomodates two spanners might be in order. Depends on your level of ambition.

Or, at that point, a headset that actually accomodates two spanners might be in order. Depends on your level of ambition.

#13

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

Yes, see posts #7 and #8.

With only one hole drilled, you'll need to remove whatever keys the washer to the steerer. A "tongue" in the case of this Peugeot (file the tongue off), or a flat in the case of most other French bikes, making the hole in the washer sort of a "D" shape. File the flat off until the hole is round.

With only one hole drilled, you'll need to remove whatever keys the washer to the steerer. A "tongue" in the case of this Peugeot (file the tongue off), or a flat in the case of most other French bikes, making the hole in the washer sort of a "D" shape. File the flat off until the hole is round.

Likes For bulgie:

#14

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

The catch is, a lot of the headsets that use race locking mechanisms like this, and the jagged-tooth style, do not have flats on the threaded race for the preferred two-spanner approach as described above. So if you decommission the locking mechanism, you need some other way to hold the threaded race in position. A strap wrench might do the trick.

Or, at that point, a headset that actually accomodates two spanners might be in order. Depends on your level of ambition.

Or, at that point, a headset that actually accomodates two spanners might be in order. Depends on your level of ambition.

Likes For oneclick:

#16

Senior Member

Join Date: Nov 2015

Posts: 4,489

Mentioned: 102 Post(s)

Tagged: 0 Thread(s)

Quoted: 1641 Post(s)

Likes: 0

Liked 831 Times

in

540 Posts

If that washer forces you to clock anything on the headset at certain increments, it's not really the best situation, IMO..

I'd rather adjust the clocking with infinite possible positions to provide appropriate amount of drag and tension at the bearings and races of the headset.

I'd rather adjust the clocking with infinite possible positions to provide appropriate amount of drag and tension at the bearings and races of the headset.

__________________

72 Line Seeker

83 Davidson Signature

84 Peugeot PSV

84 Peugeot PY10FC

84 Gitane Tour de France.

85 Vitus Plus Carbone 7

86 ALAN Record Carbonio

86 Medici Aerodynamic (Project)

88 Pinarello Montello

89 Bottecchia Professional Chorus SL

95 Trek 5500 OCLV (Project)

72 Line Seeker

83 Davidson Signature

84 Peugeot PSV

84 Peugeot PY10FC

84 Gitane Tour de France.

85 Vitus Plus Carbone 7

86 ALAN Record Carbonio

86 Medici Aerodynamic (Project)

88 Pinarello Montello

89 Bottecchia Professional Chorus SL

95 Trek 5500 OCLV (Project)

Likes For Chombi1:

#17

Newbie

Thread Starter

If that washer forces you to clock anything on the headset at certain increments, it's not really the best situation, IMO..

I'd rather adjust the clocking with infinite possible positions to provide appropriate amount of drag and tension at the bearings and races of the headset.

I'd rather adjust the clocking with infinite possible positions to provide appropriate amount of drag and tension at the bearings and races of the headset.

Just so I understand, the amount of resistance on turning the handlebars is only a function of how tight the headset nuts/etc are cranked down, right? Is there any recommended torque specs? Thus far I've just been tightening until it "feels right."

Thanks!

#18

Senior Member

Join Date: Feb 2020

Posts: 2,820

Mentioned: 49 Post(s)

Tagged: 0 Thread(s)

Quoted: 1106 Post(s)

Likes: 0

Liked 1,328 Times

in

784 Posts

I don't think it does lock you into fixed positions, but I'm replacing with a solid washer anyway, since it's broken, so moot point.

Just so I understand, the amount of resistance on turning the handlebars is only a function of how tight the headset nuts/etc are cranked down, right? Is there any recommended torque specs? Thus far I've just been tightening until it "feels right."

Thanks!

Just so I understand, the amount of resistance on turning the handlebars is only a function of how tight the headset nuts/etc are cranked down, right? Is there any recommended torque specs? Thus far I've just been tightening until it "feels right."

Thanks!

The thread pitch is 1mm.

That hole-ey washer thus limits you to adjustment steps of roughly 0.04mm.

It's not difficult (with spanners) to set the cones at intervals on the order of a degree or less.

That means adjustment steps 16 times smaller than what the washer will allow.

Half-decent balls are ground to an accuracy of 0.000025mm, which shows what kind of accuracy is desirable.

Headset bearings need little (if any) preload.

So "tightness" should not be a determining factor in the adjustment; instead lack of play should be.

If you are unsure, after setting the locknut tight against the cone lift the front wheel a few inches off the ground and bounce it; the point at which play occurs will be easily noticed as the fork rattles in the bearings.

Foe extra surety, bounce the wheel with the bars turned left and right - if anything is out-of-round or otherwise mis-aligned that will likely show it.

Likes For oneclick:

#19

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

I don't think it does lock you into fixed positions, but I'm replacing with a solid washer anyway, since it's broken, so moot point.

Just so I understand, the amount of resistance on turning the handlebars is only a function of how tight the headset nuts/etc are cranked down, right? Is there any recommended torque specs? Thus far I've just been tightening until it "feels right."

Thanks!

Just so I understand, the amount of resistance on turning the handlebars is only a function of how tight the headset nuts/etc are cranked down, right? Is there any recommended torque specs? Thus far I've just been tightening until it "feels right."

Thanks!

Then you tighten the the two screwed members (the upper race and the locknut) as tightly against each other as you can, within reason — like don't round off the nut on a soft-alloy headset like Super Record. Then re-check the adjustment because tightening the nut often changes it slightly. You may have to undo it and try again, making small adjustments.

Most bearings are OK with a little preload, i.e. just the tiniest bit tighter than the "no free play" point, because balls and races are elastic and compress under load, causing some slack to appear. I think headsets may be an exception, due to the way they're used, staying in one place a lot of the time, not spinning. I think an overly tight headset will wear out faster than one on the loose side. I still want no detectable free play, but avoid preload beyond that point. That is, err on the loose side, as long as it doesn't clunk.

Some people say to adjust it with the stem installed, on the theory that the quill expander cone or wedge being tightened shortens the steerer slightly. I'm sure that's true at a microscopic level, but I've never noticed that effect, myself. So I feel free to adjust with the stem out. Makes it easier to feel when the friction starts to go up.

EDIT: Looks like @oneclick beat me to it, covered it while I was typing.

Last edited by bulgie; 03-20-24 at 12:18 PM.

Likes For bulgie: