Seized fixed BB cup....AND stuck cotter

#1

Senior Member

Thread Starter

Join Date: Jul 2006

Location: Oakland, CA

Posts: 1,300

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Seized fixed BB cup....AND stuck cotter

Well, I seem pretty screwed

Trying to strip a Raleigh Grand Prix down to frame. All the parts are junk and will go straight in the trash, doesn't matter if I screw them up.

Driveside cotter won't budge, cotter is now bent, mushroomed, not likely to come out. Only solution I can think of is to drill it out.

I thought maybe I could remove the fixed BB cup without taking off the cotter. The fixed cup is the old style with 16mm flats identical to the adjustable cup side (ie STUPID!). The fixed cup is completely rusted and seized in place and trying to get a grip on the piddly little 16mm flats with a cone wrench just isn't doing it. The flats are already getting damaged.

My only thought is drill out the cotter then start drilling out the fixed cup in several spots and try to get some leverage on it..

Any input?

Trying to strip a Raleigh Grand Prix down to frame. All the parts are junk and will go straight in the trash, doesn't matter if I screw them up.

Driveside cotter won't budge, cotter is now bent, mushroomed, not likely to come out. Only solution I can think of is to drill it out.

I thought maybe I could remove the fixed BB cup without taking off the cotter. The fixed cup is the old style with 16mm flats identical to the adjustable cup side (ie STUPID!). The fixed cup is completely rusted and seized in place and trying to get a grip on the piddly little 16mm flats with a cone wrench just isn't doing it. The flats are already getting damaged.

My only thought is drill out the cotter then start drilling out the fixed cup in several spots and try to get some leverage on it..

Any input?

#2

.

Join Date: Aug 2005

Location: Rocket City, No'ala

Posts: 12,764

Bikes: 2014 Trek Domane 5.2, 1985 Pinarello Treviso, 1990 Gardin Shred, 2006 Bianchi San Jose

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 62 Post(s)

Likes: 0

Liked 29 Times

in

14 Posts

And what will you do when the cups are removed and completely unusable? If you have replacement cups, good for you. If not, your options are limited but still present. My LBS simply used their 68mm 24tpi tap to cut new threads and install a Shimano cartridge bottom bracket for my Sprite.

Drilling out cotters is certainly do able. I've taken an old nail punch and used it with a sledge hammer to remove stubborn cotters. If you can get one cotter off and the cup, you can remove the crankset.

If you are so inclined, drill two holes opposite each other in the cup, insert screws or nails. Use the screws/nails as leverage points for a long screwdriver and unscrew the cup. If that doesn't work, get a longer screwdriver. Have the frame fully immobilized in a workstand or vise. If this doesn't work, take sledgehammer and bash to a pulp the object of your frustration.

Have you considered shopping around for another Grand Prix bicycle that's in far better condition?

Perhaps this project has personal overtones and if so, carry on. If not, perhaps the scrap heap is the next stop for this bicycle. (so says the idiot with five frames awaiting buildup in the garage)

Drilling out cotters is certainly do able. I've taken an old nail punch and used it with a sledge hammer to remove stubborn cotters. If you can get one cotter off and the cup, you can remove the crankset.

If you are so inclined, drill two holes opposite each other in the cup, insert screws or nails. Use the screws/nails as leverage points for a long screwdriver and unscrew the cup. If that doesn't work, get a longer screwdriver. Have the frame fully immobilized in a workstand or vise. If this doesn't work, take sledgehammer and bash to a pulp the object of your frustration.

Have you considered shopping around for another Grand Prix bicycle that's in far better condition?

Perhaps this project has personal overtones and if so, carry on. If not, perhaps the scrap heap is the next stop for this bicycle. (so says the idiot with five frames awaiting buildup in the garage)

#3

Senior Member

Thread Starter

Join Date: Jul 2006

Location: Oakland, CA

Posts: 1,300

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Wait, what BB threading does this thing currently have if its not the standard 68mm diameter with 1.37" x 24tpi thread?

#4

Super Course fan

Join Date: Sep 2006

Location: Lost on the windswept plains of the Great Black Swamp

Posts: 2,720

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 6 Post(s)

Likes: 0

Liked 8 Times

in

8 Posts

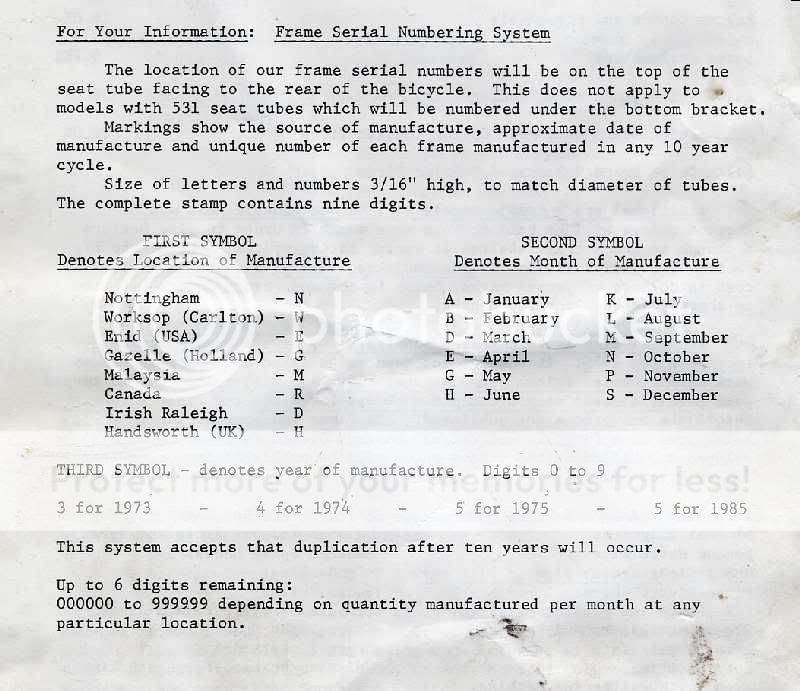

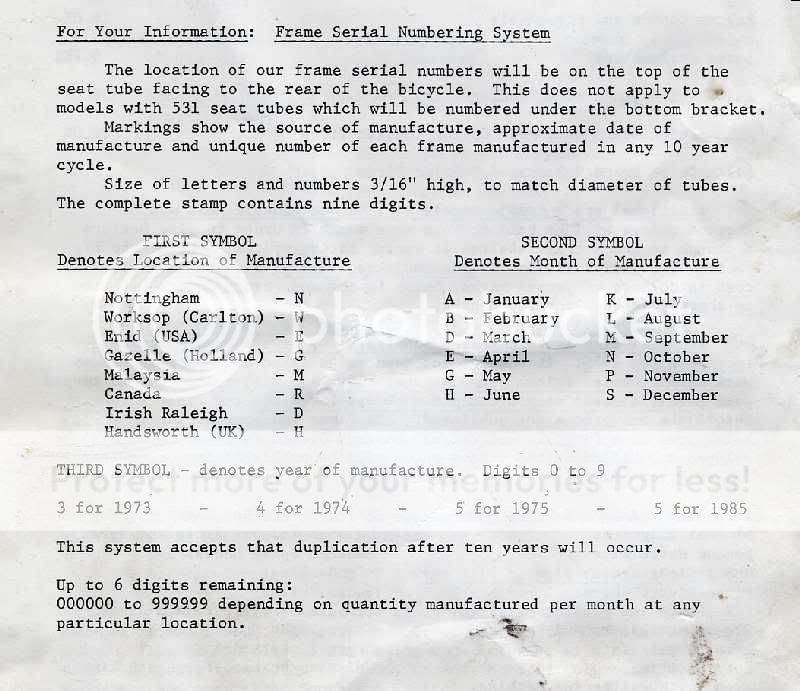

If it's a Nottingham made G.P. it's Raleigh 26tpi threaded.

Canadian and most Carlton made G.P.'s are also 26tpi.

If it's a 80's Raleigh USA G.P. it's 24tpi.

Canadian and most Carlton made G.P.'s are also 26tpi.

If it's a 80's Raleigh USA G.P. it's 24tpi.

__________________

I have a white PX-10, a Green Dawes Galaxy and an Orange Falcon, now I'm done.

I have a white PX-10, a Green Dawes Galaxy and an Orange Falcon, now I'm done.

#5

Senior Member

Thread Starter

Join Date: Jul 2006

Location: Oakland, CA

Posts: 1,300

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Well it just gets worse then haha

This is a mid to late 70s GP with the wrap around seat stay. I guess that would make it 26tpi

This is a mid to late 70s GP with the wrap around seat stay. I guess that would make it 26tpi

#6

Senior Member

Thread Starter

Join Date: Jul 2006

Location: Oakland, CA

Posts: 1,300

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Well how about this though

https://www.sheldonbrown.com/raleigh26.html

My GP has its fender eyelet above the dropout

The easiest way to identify Raleigh-built bikes is by looking at the rear dropouts. Almost all Raleigh-threaded bikes have the rear fender eyelets located directly behind the axle, instead of above it. (This doesn't apply to roadsters, which don't generally have dropouts nor fender eyelets.

My GP has its fender eyelet above the dropout

#7

Senior Member

Thread Starter

Join Date: Jul 2006

Location: Oakland, CA

Posts: 1,300

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Well instead of mucking around on the internet about the BB I went downstairs and tried to thread an English 24tpi cup into the frame and what do you know, it works  So thats good at least

So thats good at least

That still leaves me with the matter then of getting the fixed cup off (now with destruction as a valid option)

So thats good at least

So thats good at leastThat still leaves me with the matter then of getting the fixed cup off (now with destruction as a valid option)

#8

Super Course fan

Join Date: Sep 2006

Location: Lost on the windswept plains of the Great Black Swamp

Posts: 2,720

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 6 Post(s)

Likes: 0

Liked 8 Times

in

8 Posts

Well how about this though

https://www.sheldonbrown.com/raleigh26.html

My GP has its fender eyelet above the dropout

https://www.sheldonbrown.com/raleigh26.html

My GP has its fender eyelet above the dropout

My three G.P's have conventionaly placed eyelets also.

wrap around stays pretty much make it certain you have 26tpi.

Edit: you got real lucky, get us the serial number when you have a chance.

I'll bet it starts with W.

__________________

I have a white PX-10, a Green Dawes Galaxy and an Orange Falcon, now I'm done.

I have a white PX-10, a Green Dawes Galaxy and an Orange Falcon, now I'm done.

#9

Senior Member

Join Date: Mar 2007

Location: Saskatchewan

Posts: 2,465

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 3 Post(s)

Likes: 0

Liked 6 Times

in

5 Posts

Drill out the cotter. They are a soft steel and easy to drill out. I drilled out a pair on my Twenty a few weeks ago.

I use a monster size crescent wrench on fixed side BB's. Its about 3 1/2 feet long and massive.

One crank and out it comes.

This can be done in about 20 minutes.

I use a monster size crescent wrench on fixed side BB's. Its about 3 1/2 feet long and massive.

One crank and out it comes.

This can be done in about 20 minutes.

#10

Still moving forward.

Join Date: Jul 2007

Location: S.F. Peninsula

Posts: 177

Bikes: BF NWT

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I successfully removed a BB very similar to yours from a '74 Raleigh Twenty(26tpi) using Sheldon's fixed cup remover. It consists of a short bolt, washers and a nut. It worked beautifully! You can find it here. BTW, I also tried threading in a 24tpi cup into my BB. It worked fine till about halfway in, and then it stopped dead. So be sure to run it all the way in before deciding that it is a good fit. Good luck!

#11

Senior Member

Thread Starter

Join Date: Jul 2006

Location: Oakland, CA

Posts: 1,300

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I successfully removed a BB very similar to yours from a '74 Raleigh Twenty(26tpi) using Sheldon's fixed cup remover. It consists of a short bolt, washers and a nut. It worked beautifully! You can find it here. BTW, I also tried threading in a 24tpi cup into my BB. It worked fine till about halfway in, and then it stopped dead. So be sure to run it all the way in before deciding that it is a good fit. Good luck!

It only threads in halfway then stops, crap

It only threads in halfway then stops, crapI don't understand Sheldon's fixed cup removal tool though. It only works with the spindle out, correct? But I can't get the spindle out....

edit: Doh! I can once I get that stupid cotter out

Last edited by BikeManDan; 03-29-08 at 12:20 AM.

#12

Bicycle Repair Man !!!

If the cotter pin is screwed and you will NOT be re-using the cottered axle and crankarm a cut off wheel will remove it in about a minute as all you have to do is cut through the axle.

A hacksaw would also work.

I ran into the same problem when I was upgrading the bb on my Peugeot...the cranks were crap and the cotter pin was toast and after getting frustrated with trying to drive out the pin I just opted to cut it off.

You can still get new 26 tpi cups via Freeman's Cycles in London and finding a tapered axle should not be all that difficult... they also carry these.

A hacksaw would also work.

I ran into the same problem when I was upgrading the bb on my Peugeot...the cranks were crap and the cotter pin was toast and after getting frustrated with trying to drive out the pin I just opted to cut it off.

You can still get new 26 tpi cups via Freeman's Cycles in London and finding a tapered axle should not be all that difficult... they also carry these.

#13

Super Course fan

Join Date: Sep 2006

Location: Lost on the windswept plains of the Great Black Swamp

Posts: 2,720

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 6 Post(s)

Likes: 0

Liked 8 Times

in

8 Posts

That is positively a Raleigh cup, the "N" serial denotes Nottingham production. Everything from Nottingham gets the Raleigh 26tpi cup.

I'd say your bike was made in April of '74

Chart stolen from nlerner (I think),

I'd say your bike was made in April of '74

Chart stolen from nlerner (I think),

__________________

I have a white PX-10, a Green Dawes Galaxy and an Orange Falcon, now I'm done.

I have a white PX-10, a Green Dawes Galaxy and an Orange Falcon, now I'm done.

#14

Senior Member

Thread Starter

Join Date: Jul 2006

Location: Oakland, CA

Posts: 1,300

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Well gents, appreciate the help.

So I think what I'll be doing tomorrow is working to salvage the cups (given that they're not pitted). I'll hacksaw the whole spindle (thanks for that, forgot about that option), and then construct a Sheldon fixed cup remover™

So I think what I'll be doing tomorrow is working to salvage the cups (given that they're not pitted). I'll hacksaw the whole spindle (thanks for that, forgot about that option), and then construct a Sheldon fixed cup remover™

#15

Senior Member

Join Date: Jul 2000

Location: Snowy midwest

Posts: 5,391

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

There are few things as frustrating as frozen cotters. Man, I have been where you are with the mushroomed cotters. Whoever thought of that design was really thinking short-term maintanance.

One thing to consider is that if you mushroomed your cotters, I GUESS that you might not have used a support under the crank while you were whacking the cotters. The preferred method (which Sheldon taught me) is to make a wood block with a "V" cut in it to support the crank arm and to use a hardened punch when smacking the cotter. I used an old pedal axle for a punch and it works more often than not.

Anyway, if you did not use a block under the crank arm, it is quite possible that you damaged the bearing cups in the BB with violently banging on the crank with a hammer. You might consider this as you plan your path forward.

I might have some Raleigh crank spindles if you need one for the project. Drop me a line and I can look if you need one.

One thing to consider is that if you mushroomed your cotters, I GUESS that you might not have used a support under the crank while you were whacking the cotters. The preferred method (which Sheldon taught me) is to make a wood block with a "V" cut in it to support the crank arm and to use a hardened punch when smacking the cotter. I used an old pedal axle for a punch and it works more often than not.

Anyway, if you did not use a block under the crank arm, it is quite possible that you damaged the bearing cups in the BB with violently banging on the crank with a hammer. You might consider this as you plan your path forward.

I might have some Raleigh crank spindles if you need one for the project. Drop me a line and I can look if you need one.

#16

Bike Dealer since 1972

Join Date: Dec 2007

Location: Eastern North Carolina

Posts: 288

Bikes: Some of the bikes I've collected: Raleighs ( about 20), Trek ( oldest 1978 770 Columbus tubes), Mercian, Condor, Bob Jackson, Falcon, Holdsworth, Jacques Anquetil, Bianchi, LeMond, Cannondale, Schwinn, Iver Johnson, Dunelt

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 18 Post(s)

Likes: 0

Liked 71 Times

in

29 Posts

If you can't use the existing cups check with your LBS. See if they have a threadless repair bottom bracket that is made to go in a bb when the the threads are stripped out.

There are several axle lengths. Heres a link

https://74.8.32.132/nondealer/view.ph...ETS%3A+PYRAMID

There are several axle lengths. Heres a link

https://74.8.32.132/nondealer/view.ph...ETS%3A+PYRAMID

#17

Junior Member

Join Date: Jul 2005

Posts: 5

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

If Sheldon's BigBolt method won't get the fixed cup out, this will.

https://www.bikesmithdesign.com/BBTool/

https://www.bikesmithdesign.com/BBTool/

#18

holyrollin'

I'd clamp my big ViseGrip onto the wide (mushroomed) end of the cotter as tightly as possible and proceed to bash it out with a hammer. You've little hope that the bearings have not been damaged, and this percussive therapy may even help to loosen the fixed cup. Penetrating oil a plus.

#19

Senior Member

Thread Starter

Join Date: Jul 2006

Location: Oakland, CA

Posts: 1,300

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

If Sheldon's BigBolt method won't get the fixed cup out, this will.

https://www.bikesmithdesign.com/BBTool/

https://www.bikesmithdesign.com/BBTool/

Tried to hacksaw through the spindle and my measly hacksaw proved inadequate. Dremel with a cut off wheel did a much better job but because of the awkward angle I can't get all the way through it. Wish I had a Sawzall

#20

Dolce far niente

Join Date: Dec 2004

Location: Northern CA

Posts: 10,704

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 20 Post(s)

Likes: 0

Liked 17 Times

in

14 Posts

Pack the BB with black powder, from the non-drive side. There won't be anything left, but it'll be fun - as well as a bit cathartic.

Then have Stringbreaker send you some of his found beer, and toast your triumph over British engineering.

Then have Stringbreaker send you some of his found beer, and toast your triumph over British engineering.

__________________

"Love is not the dying moan of a distant violin, itís the triumphant twang of a bedspring."

S. J. Perelman

"Love is not the dying moan of a distant violin, itís the triumphant twang of a bedspring."

S. J. Perelman

#21

surly old man

Join Date: Sep 2006

Location: Carlisle, PA

Posts: 3,392

Bikes: IRO Mark V, Karate Monkey half fat, Trek 620 IGH, Cannondale 26/24 MTB, Amp Research B3, and more.

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 46 Post(s)

Likes: 0

Liked 42 Times

in

18 Posts

Sheldon's big bolt trick ALWAYS works.

jim

jim

__________________

Cross Check Nexus7, IRO Mark V, Trek 620 Nexus7, Karate Monkey half fat, IRO Model 19 fixed, Amp Research B3, Surly 1x1 half fat fixed, and more...

--------------------------

SB forever

Cross Check Nexus7, IRO Mark V, Trek 620 Nexus7, Karate Monkey half fat, IRO Model 19 fixed, Amp Research B3, Surly 1x1 half fat fixed, and more...

--------------------------

SB forever

#22

Senior Member

Join Date: Jul 2000

Location: Snowy midwest

Posts: 5,391

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

I saw that tool once in my internet travels, thanks for posting it again. Seriously considering purchasing it now...

Tried to hacksaw through the spindle and my measly hacksaw proved inadequate. Dremel with a cut off wheel did a much better job but because of the awkward angle I can't get all the way through it. Wish I had a Sawzall

Tried to hacksaw through the spindle and my measly hacksaw proved inadequate. Dremel with a cut off wheel did a much better job but because of the awkward angle I can't get all the way through it. Wish I had a Sawzall

#23

Senior Member

Join Date: Nov 2006

Posts: 92

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Well, I seem pretty screwed

Trying to strip a Raleigh Grand Prix down to frame. All the parts are junk and will go straight in the trash, doesn't matter if I screw them up.

Driveside cotter won't budge, cotter is now bent, mushroomed, not likely to come out. Only solution I can think of is to drill it out.

I thought maybe I could remove the fixed BB cup without taking off the cotter. The fixed cup is the old style with 16mm flats identical to the adjustable cup side (ie STUPID!). The fixed cup is completely rusted and seized in place and trying to get a grip on the piddly little 16mm flats with a cone wrench just isn't doing it. The flats are already getting damaged.

My only thought is drill out the cotter then start drilling out the fixed cup in several spots and try to get some leverage on it..

Any input?

Trying to strip a Raleigh Grand Prix down to frame. All the parts are junk and will go straight in the trash, doesn't matter if I screw them up.

Driveside cotter won't budge, cotter is now bent, mushroomed, not likely to come out. Only solution I can think of is to drill it out.

I thought maybe I could remove the fixed BB cup without taking off the cotter. The fixed cup is the old style with 16mm flats identical to the adjustable cup side (ie STUPID!). The fixed cup is completely rusted and seized in place and trying to get a grip on the piddly little 16mm flats with a cone wrench just isn't doing it. The flats are already getting damaged.

My only thought is drill out the cotter then start drilling out the fixed cup in several spots and try to get some leverage on it..

Any input?

#24

wheelin in the years

Join Date: Jul 2005

Location: Kansas

Posts: 666

Bikes: Some Schwinns, a Gary Fisher, some vintage lt wts

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

I have used Sheldon's removal bolt tool a couple of times, the last time though It slipped. So I used an arc welder and put a couple of spot welds on the bolt to the cup. Then put it in a bench top vice, and used the frame to spin it out. This may be an option if you plan on not re-using the cup,and can get a sopot weld on what is left of your spendel

#25

Senior Member

Thread Starter

Join Date: Jul 2006

Location: Oakland, CA

Posts: 1,300

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Or I can just break out the plasma cutter

Wish I had those kind of toys but nope, no welder, no cutters.

And you're right, 385xza, 5/8th flats, silly Brits

Wish I had those kind of toys but nope, no welder, no cutters.

And you're right, 385xza, 5/8th flats, silly Brits