Better quality rear axle for 6 speed

#51

Senior Member

Thread Starter

For me is touring and leisure long distance. My back has about 60 miles on it before I have to start riding all over my handlebars. On a loaded trip I may spend more time on the top than on the drops.

Heck if you look at the picture you'll notice that the handlebars are pretty much at the same level as the seat. On leisure distance I spend a lot of time with my hands on the bar ends in a still pretty upright position. If I was riding in a group at group drifting speeds the stem would go way down so I could be on a more aero position.

Heck if you look at the picture you'll notice that the handlebars are pretty much at the same level as the seat. On leisure distance I spend a lot of time with my hands on the bar ends in a still pretty upright position. If I was riding in a group at group drifting speeds the stem would go way down so I could be on a more aero position.

Last edited by abdon; 06-23-23 at 02:35 PM.

#52

Senior Member

Join Date: Oct 2022

Posts: 1,378

Bikes: a couple

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 563 Post(s)

Liked 863 Times

in

456 Posts

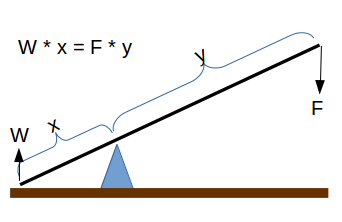

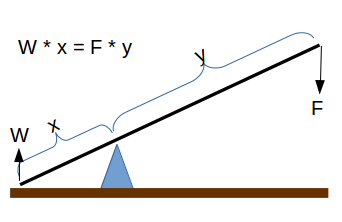

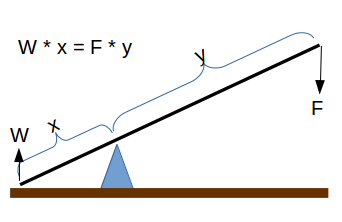

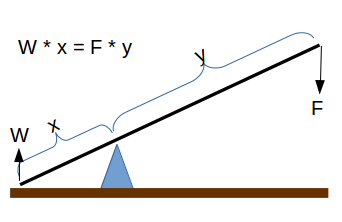

Of course the fulcrum point would remain the same. The fulcrum point being the bearing. What is changed, with a long nosed cone, is that the bending point would be moved inwards. When you move the bending point inwards away from the fulcrum point, there is now less leverage to bend the axle.

In other words, you are reinforcing the axle (with a threaded sleeve), right where it is most likely to bend.

The fulcrum(pivot) point is the ball bearing. The F is where the frame drop out is. The W is where the bend occurs. When you move W out further away from the pivot point, guess what, it takes more force to bend the axle.

In other words, you are reinforcing the axle (with a threaded sleeve), right where it is most likely to bend.

The fulcrum(pivot) point is the ball bearing. The F is where the frame drop out is. The W is where the bend occurs. When you move W out further away from the pivot point, guess what, it takes more force to bend the axle.

Understanding it is one thing, clearly explaining it as you did are completely different things.

That being said, I think you misunderstand what I was saying.

EDIT:

I said that a longer cone will not help to alleviate the bending of axles on a freewheel hub.

Reason being is the fulcrum point being the internal edge of the cone from the drop out on the drive side. the longer cone is not changing the fulcrum point.

Cassette hubs don't bend axles like freewheel hubs because of the bearings being further abart.

Notice I didn't say they don't bend axles, just that it's different and not quite as bad.

Last edited by Schweinhund; 06-23-23 at 02:40 PM.

#54

Senior Member

Join Date: Jul 2005

Location: Boulder County, CO

Posts: 4,398

Bikes: '80 Masi Gran Criterium, '12 Trek Madone, early '60s Frejus track

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 514 Post(s)

Liked 451 Times

in

339 Posts

Back in the day, all my Normandy and Zeus hubs got Campagnolo axle-cone sets, partly because they fit and partly because they were stronger and smoother. When that stuff disappeared I always went to the Wheels Mfg catalog first.

#55

Senior Member

Of course the fulcrum point would remain the same. The fulcrum point being the bearing. What is changed, with a long nosed cone, is that the bending point would be moved inwards. When you move the bending point inwards away from the fulcrum point, there is now less leverage to bend the axle.

In other words, you are reinforcing the axle (with a threaded sleeve), right where it is most likely to bend.

The fulcrum(pivot) point is the ball bearing. The F is where the frame drop out is. The W is where the bend occurs. When you move W out further away from the pivot point, guess what, it takes more force to bend the axle.

In other words, you are reinforcing the axle (with a threaded sleeve), right where it is most likely to bend.

The fulcrum(pivot) point is the ball bearing. The F is where the frame drop out is. The W is where the bend occurs. When you move W out further away from the pivot point, guess what, it takes more force to bend the axle.

In the real world, nothing is of infinite stiffness; everything deforms when subjected to force. This is true of wheel axles, bearings, races, hub bodies . . . you name it. All of these deform (flex) when force is applied. Plus, bearing lube partially displaces.

Repetitive deformation (flex) of the cantilevered end of the axle (e.g., the part between the inner bearing cone end and the point at which the force causing flexing is applied) due to forces applied by pedaling - coupled with axle threads acting as a stress riser - is what causes axle failure at the inner end of the DS cone. It's the worst on a freewheel axle because these have the longest cantilevered portion between point of application of force and point of maximum stress on the axle.

Again: the late Mr. Brandt knew both engineering and bicycling - likely far better than you and I combined. His analysis in this case appears sound.

Last edited by Hondo6; 06-24-23 at 05:16 AM.

Likes For Hondo6:

#56

Senior Member

Join Date: Jul 2014

Posts: 1,490

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 1084 Post(s)

Liked 687 Times

in

441 Posts

Go to your local bike Co-op where they will have a bucket-o-axles in every weird size and length possible. We do. We sell them for $1 used and $5 for new fancy ones. Make sure the used ones roll straight.

We have dozens of 145mm long 10mm hollow axles for rear quick-release hubs, the most common size. If 145mm is too long, then 5 minutes with a hacksaw fixes it.

No Co-op? Then beg and scavenge the parts from the wrecked wheel collection at the back of you local shop. This is one of the reasons why Shimano hubs are so great: spare parts everywhere.

We have dozens of 145mm long 10mm hollow axles for rear quick-release hubs, the most common size. If 145mm is too long, then 5 minutes with a hacksaw fixes it.

No Co-op? Then beg and scavenge the parts from the wrecked wheel collection at the back of you local shop. This is one of the reasons why Shimano hubs are so great: spare parts everywhere.

Likes For Jeff Neese:

#57

Senior Member

Join Date: Jul 2014

Posts: 1,490

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 1084 Post(s)

Liked 687 Times

in

441 Posts

+1 on Wheels Manufacturing, but as Dave said, check with your local LBS or Co-op first.

Yes, we all know that this configuration is more prone to bent axles, but that doesn't mean they all bend. I've had plenty of bikes with 6-speed freewheels, have ridden many thousands of miles on them, and the only bent axle I've encountered was that way when I bought it. It was an easy replacement and it's been fine ever since. I'm with you on not wanting to buy a $10 Chinese-made axle.

Yes, we all know that this configuration is more prone to bent axles, but that doesn't mean they all bend. I've had plenty of bikes with 6-speed freewheels, have ridden many thousands of miles on them, and the only bent axle I've encountered was that way when I bought it. It was an easy replacement and it's been fine ever since. I'm with you on not wanting to buy a $10 Chinese-made axle.

Likes For Jeff Neese:

#58

Senior Member

Join Date: Aug 2009

Posts: 2,396

Mentioned: 14 Post(s)

Tagged: 0 Thread(s)

Quoted: 1562 Post(s)

Liked 1,734 Times

in

974 Posts

You might want to actually read the links I posted. The DS dropout is not where the force causing the bending moment on a freewheel rear axle is applied. Rather, it's applied at the rear sprockets during pedaling.

In the real world, nothing is of infinite stiffness; everything deforms when subjected to force. This is true of wheel axles, bearings, races, hub bodies . . . you name it. All of these deform (flex) when force is applied. Plus, bearing lube partially displaces.

Repetitive deformation (flex) of the cantilevered end of the axle (e.g., the part between the inner bearing cone end and the point at which the force causing flexing is applied) due to forces applied by pedaling - coupled with axle threads acting as a stress riser - is what causes axle failure at the inner end of the DS cone. It's the worst on a freewheel axle because these have the longest cantilevered portion between point of application of force and point of maximum stress on the axle.

Again: the late Mr. Brandt knew both engineering and bicycling - likely far better than you and I combined. His analysis in this case appears sound.

In the real world, nothing is of infinite stiffness; everything deforms when subjected to force. This is true of wheel axles, bearings, races, hub bodies . . . you name it. All of these deform (flex) when force is applied. Plus, bearing lube partially displaces.

Repetitive deformation (flex) of the cantilevered end of the axle (e.g., the part between the inner bearing cone end and the point at which the force causing flexing is applied) due to forces applied by pedaling - coupled with axle threads acting as a stress riser - is what causes axle failure at the inner end of the DS cone. It's the worst on a freewheel axle because these have the longest cantilevered portion between point of application of force and point of maximum stress on the axle.

Again: the late Mr. Brandt knew both engineering and bicycling - likely far better than you and I combined. His analysis in this case appears sound.

He places the w right where I said it was- just behind the cone. Therefore extending the cone in that direction, would move that w point further away from X, which is the pivot point. Hence less leverage. And that is the case whether you think the bending force is coming from the sprocket or the DS dropout. What exactly is your objection here?