Theory of locking up the pawl in a freehub to create a fixed gear wheel?

#26

Old fart

Join Date: Nov 2004

Location: Appleton WI

Posts: 24,790

Bikes: Several, mostly not name brands.

Mentioned: 153 Post(s)

Tagged: 0 Thread(s)

Quoted: 3590 Post(s)

Liked 3,401 Times

in

1,935 Posts

#27

Junior Member

Join Date: Dec 2020

Location: Nr. Helston, Cornwall. U.K.

Posts: 13

Bikes: One whole Raleigh mountin bike,and lots of other bit,parts,and left over cut offs.

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 5 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Tack weld or JB weld the pawls to the spur gear......It's like making a Lincoln Locker for a bicycle.

There's no stress when peddling....the pawls will be engaged when your ready to stop.

As long as the pawls stay on the spur gear,no problem.

Whether the pawl pivots can take that stress or not,that's another story.....

There's no stress when peddling....the pawls will be engaged when your ready to stop.

As long as the pawls stay on the spur gear,no problem.

Whether the pawl pivots can take that stress or not,that's another story.....

I used it again later on as a freewheel sprocket again simply by carefully grinding off the tacks. All quite safe..

Back to its original purpose.

Last edited by Swarf; 01-05-21 at 11:09 AM. Reason: spelling error.

#28

n00b

Join Date: Jan 2008

Location: Austin, TX

Posts: 1,397

Bikes: Surly Karate Monkey, Twin Six Standard Rando

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 428 Post(s)

Liked 466 Times

in

273 Posts

glad to see you cleared that up, now that it's been seven years since this topic was last brought up.

Likes For mack_turtle:

#29

Newbie

Join Date: Mar 2024

Posts: 21

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 15 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

I just figured the guy has brakes on his bike......or is this a track bike?

If you need to lock the wheel to brake.....Degrease,mix up a couple tubes of JB/epoxy/casting resin and fill the freehub with it,bearings and all......you won't compress that.

If your good with your hands or have some machinery,make an aluminum slug to replace the ratchet.

If the parts are made of the same material,you can tig weld them together if you can get to them.

If you need to lock the wheel to brake.....Degrease,mix up a couple tubes of JB/epoxy/casting resin and fill the freehub with it,bearings and all......you won't compress that.

If your good with your hands or have some machinery,make an aluminum slug to replace the ratchet.

If the parts are made of the same material,you can tig weld them together if you can get to them.

In the end, the three options you listed seems to be the best.

I thought that if I could double up the freewheels and press fit the second one, flipped, in place of a bearing, it would be the ideal "safe" and no-damage/reversible way, but finally decided against it.

I do think that jamming the front of the pawl with a wedge is better that jamming the pawl from underneath, although both are possible at the same time.

Anyway its a bit scary to leave the pawls just jammed like that without pouring like epoxy on it, which makes it much safer but less reversible.

As much as I enjoyed reading this 10 years old

#30

Senior Member

Join Date: Jul 2005

Posts: 5,994

Mentioned: 26 Post(s)

Tagged: 0 Thread(s)

Quoted: 2495 Post(s)

Liked 739 Times

in

523 Posts

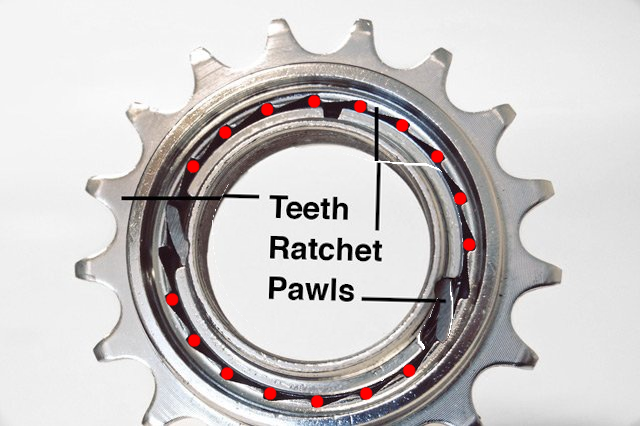

The pawl system in ANY freewheel or freehub is optimized to transfer torque in only one direction. In that direction, the main responsibility for the transfer of torque is taken on by the geometry of the moving pawl and fixed mating surface. Once locked in place the pawl couldn't retract even if it wanted to. In the reverse situation there is no assistance from the hard angles of the mating surfaces. A 'sliding' component creeps in that weakens (deliberately) the ultimate amount of resistance to the torque there can be. Will what remains be enough? <shrug>. Maybe enough for a proof of concept. Then, one day when all concerns are gone ... ... ... It seems though that as early as post #2, someone that has thought the situation out came up with some good alternatives to try.

#31

Newbie

Join Date: Mar 2024

Posts: 21

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 15 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

That‘s not my case, as I alluded to previously, my goal is not to ride a fixed gear bike, so all of the alternatives suggested in this thread offer no solution for me. If you‘re curious or have suggestions, you can see my thread on this same forum.

The pawl system in ANY freewheel or freehub is optimized to transfer torque in only one direction. In that direction, the main responsibility for the transfer of torque is taken on by the geometry of the moving pawl and fixed mating surface. Once locked in place the pawl couldn't retract even if it wanted to. In the reverse situation there is no assistance from the hard angles of the mating surfaces. A 'sliding' component creeps in that weakens (deliberately) the ultimate amount of resistance to the torque there can be. Will what remains be enough? <shrug>. Maybe enough for a proof of concept. Then, one day when all concerns are gone ... ... ...

Modifying the pawls’ freewheel design to make it transfer torque in both direction can actually be made safely and reliably, as demonstrated by SRAM with their TORPEDO® HUB, but with quite heavy modifications that are very impractical for us to do (symmetrical ratchet and adding pawls facing opposite side)

The obvious minimum effort way to imitate that method is to double up the freewheels, flipping one of them. You need space to do that, though.

If you have the ability, welding it is also not so bad of a solution.

Jamming the pawls doesn‘t feel very safe, in particular in regards to the lack of hard angles of the mating surfaces, as you said.

However, I do think that jamming the pawls with something that, by design, only jam itself further, the further the torque is applied, should provide a decent amount of resistance to the torque applied, provided the amount of wear over time stays similar to the wear of the original design.

I think putting a wedge in the front of the pawl is good enough to jam the freewheel for any amount of torque the freewheel will take. This is only possible with the type of pawl freewheel that leaves a gap in front of the pawl, though.

But the issue is more on reducing the amount of wear over time, and for that, putting another wedge under the pawl, using alloys of similar hardness (re-using some old grinded pawls as wedge for example) and putting it all in JB weld, epoxy or whatever, should help tremendously, I think.

Last edited by Jean Daspry; 03-22-24 at 08:33 AM.

#32

Senior Member

Join Date: Apr 2011

Posts: 7,067

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4409 Post(s)

Liked 1,563 Times

in

1,026 Posts

It would be stupid to do this and expect to safely use it to slow the bike in town. The act of backpedalling against the slightly slope of the freewheeling direction is an invitation to shear off the pawls, their pivots or otherwise cause the hub to fail. It's like expecting to be able to hang a brick wall upside down just because the mortar seems to do a great job sticking the bricks together rightside up.

#33

Newbie

Join Date: Mar 2024

Posts: 21

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 15 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

You are right in that the slight slope of the freewheeling direction is a big obstacle to that method.

Keep in mind it‘s always possible to grind the slope into a notch, and to make it the same kind of “symmetrical” ratchet as the kind in the SRAM TORPEDO hub. Obviously not reasonable to do that for every notch of the ratchet, but very possible for only the 3 notches where the pawls are jammed into.

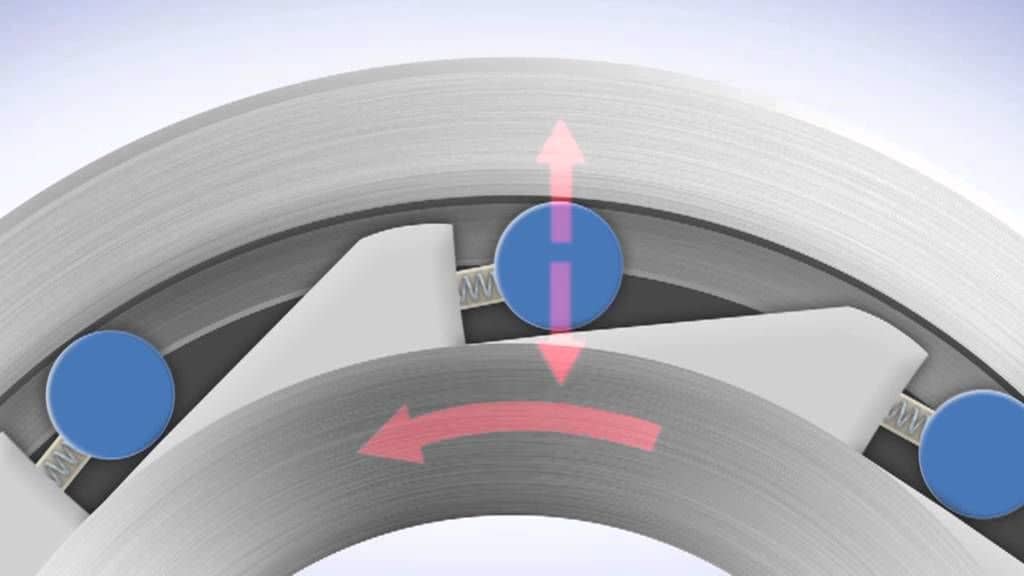

Other than that, slight slopes and self-jamming clutches to transfer torque with no notches is the premise of two of the more robust versions of the pawl&ratchet freewheel design, you might already have heard of them as sprag clutches and roller clutches.

I think there is a little bit of that principle in the self-jamming of the pawls I suggested, don‘t you think so?

I would like you to entertain the idea I proposed of jamming the front of the pawl (not the underside) with a wedge (again, I‘m sorry I can‘t yet illustrate that with a picture, my description must be very lacking to explain my idea) and explain to me what makes you think that it would lead to the pawls being sheared off, or the pivots to fail. I would be happy to look at some figures describing the type of torque force in application here, with the type of compression forces required to break off pawls or their pivots.

As I said, I don’t think the amount of torque the jammed pawls can take is much less than the original design, but I do think the amount of wear over time could be much more of an issue.

#34

Senior Member

Join Date: Apr 2011

Posts: 7,067

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4409 Post(s)

Liked 1,563 Times

in

1,026 Posts

Very interesting analogy with the brick wall, as hanging bricks, upside down wall, and slight slope personally make me think of the keystone jammed between voussoirs in a vault. The weight of the bricks themselves is jamming them and is what help the arch to hold itself above our heads. To each their own architectural style.

I guess what you are referring to is jamming the pawls to lock the freewheel.

You are right in that the slight slope of the freewheeling direction is a big obstacle to that method.

Keep in mind it‘s always possible to grind the slope into a notch, and to make it the same kind of “symmetrical” ratchet as the kind in the SRAM TORPEDO hub. Obviously not reasonable to do that for every notch of the ratchet, but very possible for only the 3 notches where the pawls are jammed into.

Other than that, slight slopes and self-jamming clutches to transfer torque with no notches is the premise of two of the more robust versions of the pawl&ratchet freewheel design, you might already have heard of them as sprag clutches and roller clutches.

I think there is a little bit of that principle in the self-jamming of the pawls I suggested, don‘t you think so?

I would like you to entertain the idea I proposed of jamming the front of the pawl (not the underside) with a wedge (again, I‘m sorry I can‘t yet illustrate that with a picture, my description must be very lacking to explain my idea) and explain to me what makes you think that it would lead to the pawls being sheared off, or the pivots to fail. I would be happy to look at some figures describing the type of torque force in application here, with the type of compression forces required to break off pawls or their pivots.

As I said, I don’t think the amount of torque the jammed pawls can take is much less than the original design, but I do think the amount of wear over time could be much more of an issue.

I guess what you are referring to is jamming the pawls to lock the freewheel.

You are right in that the slight slope of the freewheeling direction is a big obstacle to that method.

Keep in mind it‘s always possible to grind the slope into a notch, and to make it the same kind of “symmetrical” ratchet as the kind in the SRAM TORPEDO hub. Obviously not reasonable to do that for every notch of the ratchet, but very possible for only the 3 notches where the pawls are jammed into.

Other than that, slight slopes and self-jamming clutches to transfer torque with no notches is the premise of two of the more robust versions of the pawl&ratchet freewheel design, you might already have heard of them as sprag clutches and roller clutches.

I think there is a little bit of that principle in the self-jamming of the pawls I suggested, don‘t you think so?

I would like you to entertain the idea I proposed of jamming the front of the pawl (not the underside) with a wedge (again, I‘m sorry I can‘t yet illustrate that with a picture, my description must be very lacking to explain my idea) and explain to me what makes you think that it would lead to the pawls being sheared off, or the pivots to fail. I would be happy to look at some figures describing the type of torque force in application here, with the type of compression forces required to break off pawls or their pivots.

As I said, I don’t think the amount of torque the jammed pawls can take is much less than the original design, but I do think the amount of wear over time could be much more of an issue.

Likes For Kontact:

#35

Newbie

Join Date: Mar 2024

Posts: 21

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 15 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Seriously though, as you said, the bigger the contact area, the better. I would not say it has no chance of failing, especially given time and a little wear.

The "permanent" aspect is not desirable, but if it is the only way to make it safe enough for long term use, so be it.

I wonder why you prefer soft steel nails that would obviously wear faster against the hard treated surfaces of the freewheel, is it because you think using the plastic deformation of the steel is the best way to jam it harder?

Your suggestion actually begins to resemble a lot like a roller clutch, except in a roller clutch I do think the rollers are of similar hardness, if not harder, than the mating surfaces.

The only issue I have with this, is that in a roller clutch, the “rollers” have to be free, in order to jam themselves further, the further the torque is applied. So it would be counter-productive to pour epoxy on it after, and you would solely count on the friction of the nails/rollers to jam the freewheel.

P.S. : I can now post pictures!

What was suggested earlier in the thread (with spokes or shims, or keyways):

What I suggested :

What you suggest :

An exemple of a roller clutch :

Last edited by Jean Daspry; 03-22-24 at 08:26 AM.

#36

Senior Member

Join Date: Apr 2011

Posts: 7,067

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4409 Post(s)

Liked 1,563 Times

in

1,026 Posts

Soft steel because you use oversized parts and you peen them into the voids so there is zero play when you're done.

#37

Senior Member

Join Date: Jul 2006

Location: San Jose (Willow Glen) Ca

Posts: 9,847

Bikes: Kirk Custom JK Special, '84 Team Miyata,(dura ace old school) 80?? SR Semi-Pro 600 Arabesque

Mentioned: 106 Post(s)

Tagged: 0 Thread(s)

Quoted: 2338 Post(s)

Liked 2,827 Times

in

1,543 Posts

It would be stupid to do this and expect to safely use it to slow the bike in town. The act of backpedalling against the slightly slope of the freewheeling direction is an invitation to shear off the pawls, their pivots or otherwise cause the hub to fail. It's like expecting to be able to hang a brick wall upside down just because the mortar seems to do a great job sticking the bricks together rightside up.

In addition coaster brakes are not as good as stopping and being able to control stopping as other brake systems. you are adding ebike power and would need better braking

__________________

Life is too short not to ride the best bike you have, as much as you can

(looking for Torpado Super light frame/fork or for Raleigh International frame fork 58cm)

Life is too short not to ride the best bike you have, as much as you can

(looking for Torpado Super light frame/fork or for Raleigh International frame fork 58cm)