Is this just a dust cap or does it have to be very tight?

#1

Senior Member

Thread Starter

Join Date: May 2008

Location: Toronto, Canada

Posts: 909

Bikes: (shortlist) Cyclops, Marinoni, Mariposa, Air Firday, Pocket Rocket Pro, NWT, SLX Fuso, Claude Pottie (France) x3, Masi Team 3v, Lemond Zurich, Bianchi OS

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 176 Post(s)

Liked 38 Times

in

30 Posts

Is this just a dust cap or does it have to be very tight?

I am having a bit of if trouble with my LH crank arm coming loose.

I think this is theHollowtech Correction: SRAM GXP system - outboard cups, splined BB axle - except that one inner bolt threads into the axle pulling the crank arm tight. The outer piece threads into the crank arm hole itself, like an old style dust cap.

But with that outer piece just snug my crank arm keeps loosening off.

So i am wondering if the outer cap is not just for show but needs to be cinched down very tight too, to maybe prevent the inner bolt from backing off...

I think this is the

But with that outer piece just snug my crank arm keeps loosening off.

So i am wondering if the outer cap is not just for show but needs to be cinched down very tight too, to maybe prevent the inner bolt from backing off...

Last edited by pstock; 11-12-23 at 08:46 AM.

#2

Senior Member

Join Date: Apr 2019

Location: UK

Posts: 1,463

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 708 Post(s)

Liked 477 Times

in

354 Posts

I donít think thatís hollowtech II. Seems to work more like GXP. I think that end cap has to be tightened very tight, like 30-40Nm with an 8mm but Iíd be looking for official guidance.

#3

Senior Member

Thread Starter

Join Date: May 2008

Location: Toronto, Canada

Posts: 909

Bikes: (shortlist) Cyclops, Marinoni, Mariposa, Air Firday, Pocket Rocket Pro, NWT, SLX Fuso, Claude Pottie (France) x3, Masi Team 3v, Lemond Zurich, Bianchi OS

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 176 Post(s)

Liked 38 Times

in

30 Posts

You are correct. GXP.

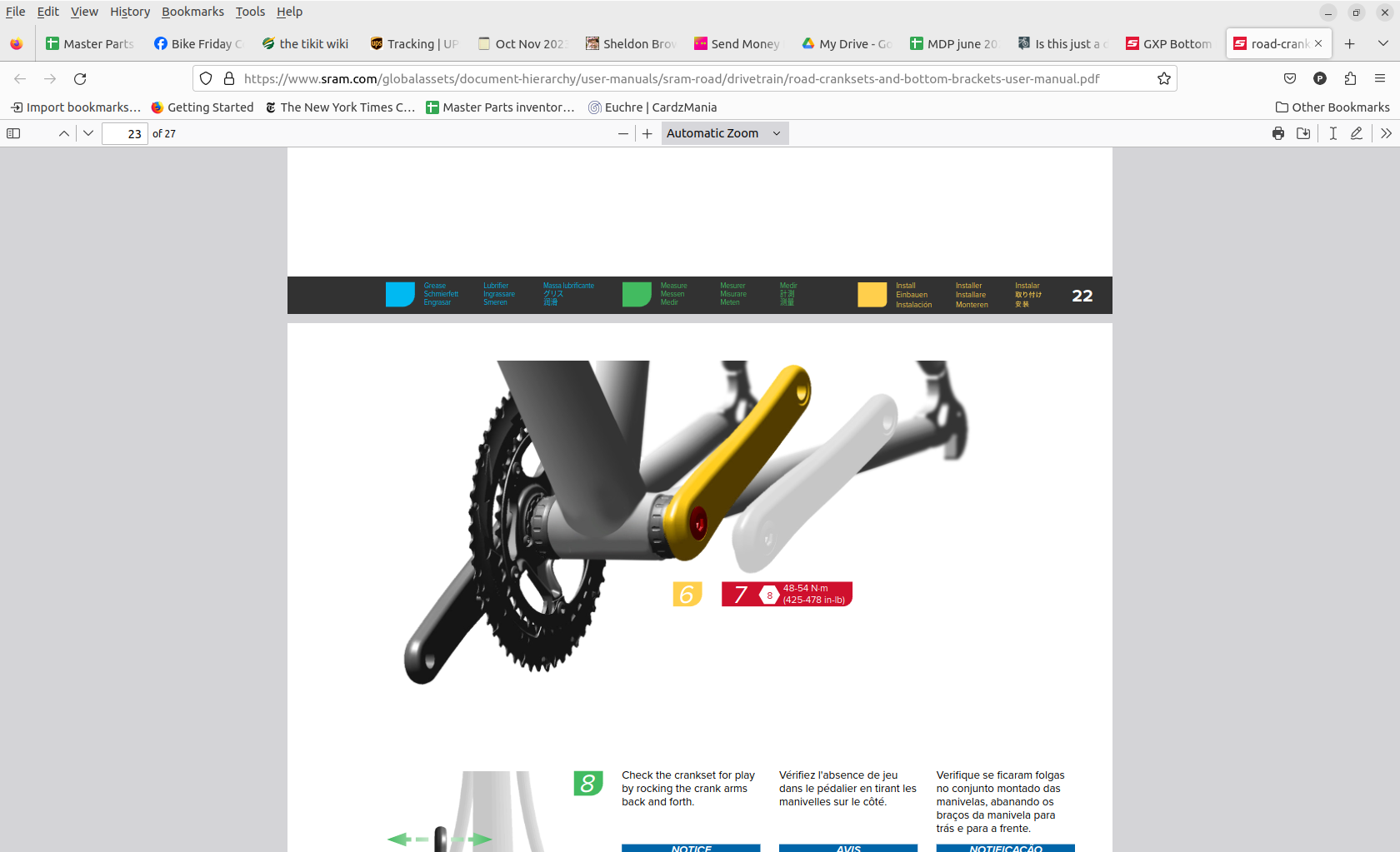

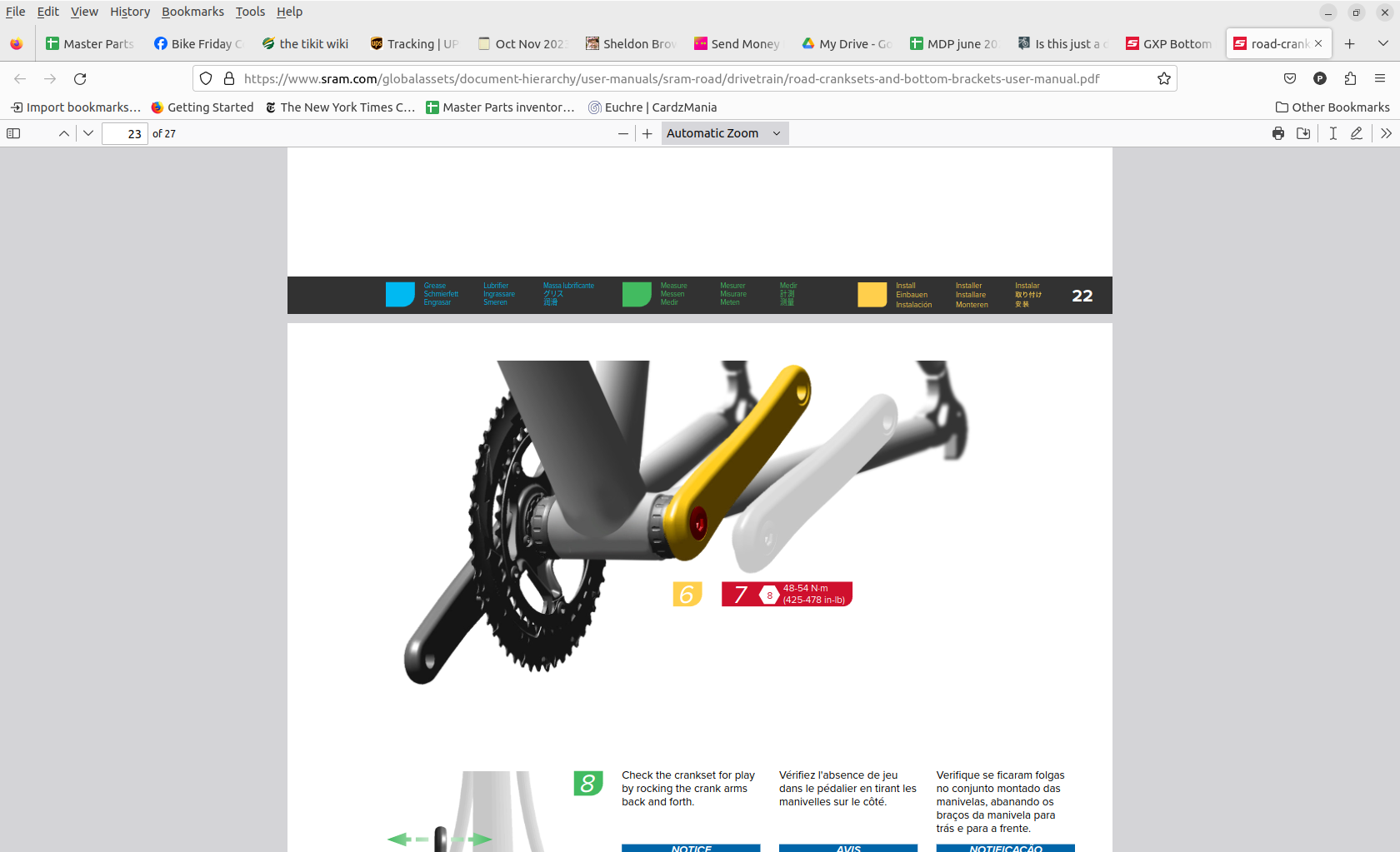

and the manual seems to call for a #8 tightened to 48-54 N-m

(though this instruction sheet doesn't really show two NDS bolts. I might have the wrong instruction sheet.)

and the manual seems to call for a #8 tightened to 48-54 N-m

(though this instruction sheet doesn't really show two NDS bolts. I might have the wrong instruction sheet.)

#4

I'm good to go!

Join Date: Jul 2017

Location: Mississippi

Posts: 15,363

Bikes: Tarmac Disc Comp Di2 - 2020

Mentioned: 53 Post(s)

Tagged: 0 Thread(s)

Quoted: 6393 Post(s)

Liked 4,989 Times

in

3,434 Posts

Whatever that crank is, it looks like that is supposed to be a self extracting crank. The thing you are calling a cover is what you stick a hex key through to get to the crank arm bolt. When you unscrew the crank arm bolt it applies force against that "cover" and pushes the crank arm off the spindle.

I'm wondering if your spindle is too short for that BB shell or do you have spacers under the external cups that shouldn't be there for your particular BB shell and it's not letting you get the crank arm all the way on the spindle.

Is this crankset and BB original to the bike or added later?

I'm wondering if your spindle is too short for that BB shell or do you have spacers under the external cups that shouldn't be there for your particular BB shell and it's not letting you get the crank arm all the way on the spindle.

Is this crankset and BB original to the bike or added later?

Likes For Iride01:

#5

Senior Member

Join Date: Apr 2019

Location: UK

Posts: 1,463

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 708 Post(s)

Liked 477 Times

in

354 Posts

On mine, it has two torques printed on the arm, much higher for 8mm, like you have a choice between them, which honestly I donít understand and just always use 8 as the 10 is pretty shallow.

Normally thereís a wave washer under the nds crank arm (maybe itís on the drive side actually, think I slid it onto the spindle) and iirc a washer that prevents the bearing outer race being contacted.

#6

Senior Member

Join Date: Apr 2011

Posts: 7,455

Mentioned: 43 Post(s)

Tagged: 0 Thread(s)

Quoted: 4657 Post(s)

Liked 1,796 Times

in

1,172 Posts

You guys don't know what you are talking about.

The 8mm is the crank bolt. The 10mm is the extractor cap.

If the bike uses external bearings, the drive side should have no spacers or washers.

There are directions available.

The 8mm is the crank bolt. The 10mm is the extractor cap.

If the bike uses external bearings, the drive side should have no spacers or washers.

There are directions available.

Likes For Kontact:

#8

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 13,035

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 131 Post(s)

Tagged: 0 Thread(s)

Quoted: 4896 Post(s)

Liked 4,067 Times

in

2,636 Posts

@Kontact, question. Is this like the old square taper where the cranks tend to "rock" and loosen the snug fit against the bolt when the bike is ridden? (With the square taper cranks, each time you re-tighten to the proper initial torque, you push the crank a little further in onto the taper. Eventually, you can push the crank in so far it cracks; the cracks starting at the corners of the taper square.

So, any danger of doing damage by being "too careful" and repeatably tightening the bolt to spec?

So, any danger of doing damage by being "too careful" and repeatably tightening the bolt to spec?

#9

Senior Member

Join Date: Apr 2011

Posts: 7,455

Mentioned: 43 Post(s)

Tagged: 0 Thread(s)

Quoted: 4657 Post(s)

Liked 1,796 Times

in

1,172 Posts

@Kontact, question. Is this like the old square taper where the cranks tend to "rock" and loosen the snug fit against the bolt when the bike is ridden? (With the square taper cranks, each time you re-tighten to the proper initial torque, you push the crank a little further in onto the taper. Eventually, you can push the crank in so far it cracks; the cracks starting at the corners of the taper square.

So, any danger of doing damage by being "too careful" and repeatably tightening the bolt to spec?

So, any danger of doing damage by being "too careful" and repeatably tightening the bolt to spec?

I don't know what is wrong with the OPs cranks, but given that people seem to have little understanding of how GXP works, he could be tightening the 10mm cap, or have a bunch of spacers on the drive side that are interfering with getting the crank tight.

GXP has as stepped spindle. The spindle goes through the right bearing and just floats. The step butts up against the inside of the left bearing and the left crankarm butts up against the outside of the left bearing. The crank bolt just pinches the left bearing between the spindle step and the crank arm.

There should be a splined bearing cover on the left between bearing and crank. There should be nothing on the right - the right bearing has a built in cover. If you put spacers on the right you might be compressing them as you tighten the fixing bolt rather than pinching the left bearing.

The above is how it works with threaded external cups. With various internal bearing systems that press into the frame, the attachment is all the same but a spacer and wave spring is used on the right side to keep the left bearing from drifting to the left out of the frame.

#10

Senior Member

Join Date: Apr 2019

Location: UK

Posts: 1,463

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 708 Post(s)

Liked 477 Times

in

354 Posts

Entirely possible

hmm, I need to look at mine again. Didnít touch the 10mm last time. Wonder if thatís a problem. Ridden a lot on it and never noticed an issue.

Mineís internal pressfit bearings so that makes sense.

No it was me who said that, not him.

The 8mm is the crank bolt. The 10mm is the extractor cap.

If the bike uses external bearings, the drive side should have no spacers or washers.

he could be tightening the 10mm cap, or have a bunch of spacers on the drive side that are interfering with getting the crank tight.

No it was me who said that, not him.

Last edited by choddo; 11-12-23 at 12:32 PM.

#11

Senior Member

Join Date: Jul 2005

Location: Boulder County, CO

Posts: 4,457

Bikes: '80 Masi Gran Criterium, '12 Trek Madone, early '60s Frejus track

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 531 Post(s)

Liked 477 Times

in

359 Posts

Hand-tight should be sufficient to keep the extractor nut from rattling loose. Always make sure it's tight and clean before trying to remove the crank. I like to make sure the threads and interface with the crank bolt are thoroughly greased.

Likes For oldbobcat:

#12

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 39,105

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 141 Post(s)

Tagged: 1 Thread(s)

Quoted: 6000 Post(s)

Liked 2,940 Times

in

1,629 Posts

Likewise, be sure to grease as noted for the same reason.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

ďOne accurate measurement is worth a thousand expert opinionsĒ - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

ďOne accurate measurement is worth a thousand expert opinionsĒ - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

#14

Senior Member

Join Date: Apr 2011

Posts: 7,455

Mentioned: 43 Post(s)

Tagged: 0 Thread(s)

Quoted: 4657 Post(s)

Liked 1,796 Times

in

1,172 Posts

Likes For Kontact:

Likes For oldbobcat:

#16

Senior Member

Join Date: Apr 2011

Posts: 7,455

Mentioned: 43 Post(s)

Tagged: 0 Thread(s)

Quoted: 4657 Post(s)

Liked 1,796 Times

in

1,172 Posts

#18

Senior Member

Join Date: Jun 2002

Location: San Jose, CA

Posts: 3,756

Bikes: Too many bikes, too little time to ride

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 463 Post(s)

Liked 492 Times

in

339 Posts

The outer cover enables the self extraction, but it also helps keep the crank bolt (the bolt that threads onto the spindle) in place. The outer cover doesn't need to be super tight but it definitely should be tighter than finger tight. Torque it down a bit with the crank arm off the spindle (this ensures there's no room for the crank bolt itself to "walk" its way loose during normal use (which is what I suspect might be happening), and then torque down the crank bolt to spec onto the spindle.

#19

Senior Member

Join Date: Apr 2019

Location: UK

Posts: 1,463

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 708 Post(s)

Liked 477 Times

in

354 Posts

I just took a look at mine (which is a Quarq power crank but I suspect they are the same spec) and it says 12-15Nm for the 10mmcap, now that I understand what it is.

Thatís pretty damn tight.

Thatís pretty damn tight.

#20

Senior Member

Thread Starter

Join Date: May 2008

Location: Toronto, Canada

Posts: 909

Bikes: (shortlist) Cyclops, Marinoni, Mariposa, Air Firday, Pocket Rocket Pro, NWT, SLX Fuso, Claude Pottie (France) x3, Masi Team 3v, Lemond Zurich, Bianchi OS

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 176 Post(s)

Liked 38 Times

in

30 Posts

I am back. (sorry, I seem to have have had Notifications turned on for this thread)

indeed it is 8mm for the bolt that affixes the crank arm to the BB spindle and a 10mm that tightens the outer "cap"

however, with the 8mm inner bolt tightened up VERY tight the 10mm outer "cap" (which I assume is meant to hold the inner bolt in place) does not engage with the inner bolt face. so it is not doing anything. it appears to bottom out on its threads before engaging with the inner bolt face

and so the crank arm keeps coming loose

it must need a washer in there to fill the void. tomorrow I will disassemble another bike using the same system and see what I am missing.

I could not find any documentation that exactly matched this setup.

indeed it is 8mm for the bolt that affixes the crank arm to the BB spindle and a 10mm that tightens the outer "cap"

however, with the 8mm inner bolt tightened up VERY tight the 10mm outer "cap" (which I assume is meant to hold the inner bolt in place) does not engage with the inner bolt face. so it is not doing anything. it appears to bottom out on its threads before engaging with the inner bolt face

and so the crank arm keeps coming loose

it must need a washer in there to fill the void. tomorrow I will disassemble another bike using the same system and see what I am missing.

I could not find any documentation that exactly matched this setup.

#21

Senior Member

Join Date: Jan 2009

Location: San Diego, CA

Posts: 3,750

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 865 Post(s)

Liked 1,122 Times

in

775 Posts

however, with the 8mm inner bolt tightened up VERY tight the 10mm outer "cap" (which I assume is meant to hold the inner bolt in place) does not engage with the inner bolt face. so it is not doing anything. it appears to bottom out on its threads before engaging with the inner bolt face

and so the crank arm keeps coming loose

it must need a washer in there to fill the void. tomorrow I will disassemble another bike using the same system and see what I am missing.

and so the crank arm keeps coming loose

it must need a washer in there to fill the void. tomorrow I will disassemble another bike using the same system and see what I am missing.

Last edited by Crankycrank; 11-20-23 at 08:39 PM.

#22

Senior Member

Join Date: Apr 2011

Posts: 7,455

Mentioned: 43 Post(s)

Tagged: 0 Thread(s)

Quoted: 4657 Post(s)

Liked 1,796 Times

in

1,172 Posts

I am back. (sorry, I seem to have have had Notifications turned on for this thread)

indeed it is 8mm for the bolt that affixes the crank arm to the BB spindle and a 10mm that tightens the outer "cap"

however, with the 8mm inner bolt tightened up VERY tight the 10mm outer "cap" (which I assume is meant to hold the inner bolt in place) does not engage with the inner bolt face. so it is not doing anything. it appears to bottom out on its threads before engaging with the inner bolt face

and so the crank arm keeps coming loose

it must need a washer in there to fill the void. tomorrow I will disassemble another bike using the same system and see what I am missing.

I could not find any documentation that exactly matched this setup.

indeed it is 8mm for the bolt that affixes the crank arm to the BB spindle and a 10mm that tightens the outer "cap"

however, with the 8mm inner bolt tightened up VERY tight the 10mm outer "cap" (which I assume is meant to hold the inner bolt in place) does not engage with the inner bolt face. so it is not doing anything. it appears to bottom out on its threads before engaging with the inner bolt face

and so the crank arm keeps coming loose

it must need a washer in there to fill the void. tomorrow I will disassemble another bike using the same system and see what I am missing.

I could not find any documentation that exactly matched this setup.

Did you check that there aren't any washers on the driveside between the crank and the bearing?

Take the crankarm off and look at the splines and their mates on the spindle. If the crank arm splines are damaged the arm can pivot back and forth on spindle and back the bolt out.

Likes For Kontact:

#23

Senior Member

Join Date: Apr 2019

Location: UK

Posts: 1,463

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 708 Post(s)

Liked 477 Times

in

354 Posts

I did check mine after this discussion. And while it has different bearings, thereís nothing between the cap and the crank bolt. Kontactís suggestion that there might be a washer, possibly the wave washer I have installed on mine, on the drive side seems the most likely explanation for the anomaly.

I donít think a normal extractor tool can work on this can it? It would push against the inner bolt which is part of the crank arm youíre trying to remove.

I donít think a normal extractor tool can work on this can it? It would push against the inner bolt which is part of the crank arm youíre trying to remove.

#24

Senior Member

Join Date: Apr 2011

Posts: 7,455

Mentioned: 43 Post(s)

Tagged: 0 Thread(s)

Quoted: 4657 Post(s)

Liked 1,796 Times

in

1,172 Posts

I did check mine after this discussion. And while it has different bearings, thereís nothing between the cap and the crank bolt. Kontactís suggestion that there might be a washer, possibly the wave washer I have installed on mine, on the drive side seems the most likely explanation for the anomaly.

I donít think a normal extractor tool can work on this can it? It would push against the inner bolt which is part of the crank arm youíre trying to remove.

I donít think a normal extractor tool can work on this can it? It would push against the inner bolt which is part of the crank arm youíre trying to remove.

Likes For Kontact:

#25

Senior Member

Thread Starter

Join Date: May 2008

Location: Toronto, Canada

Posts: 909

Bikes: (shortlist) Cyclops, Marinoni, Mariposa, Air Firday, Pocket Rocket Pro, NWT, SLX Fuso, Claude Pottie (France) x3, Masi Team 3v, Lemond Zurich, Bianchi OS

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 176 Post(s)

Liked 38 Times

in

30 Posts

Please read all the stuff I wrote for your in your thread.

Did you check that there aren't any washers on the driveside between the crank and the bearing?

Take the crankarm off and look at the splines and their mates on the spindle. If the crank arm splines are damaged the arm can pivot back and forth on spindle and back the bolt out.

Did you check that there aren't any washers on the driveside between the crank and the bearing?

Take the crankarm off and look at the splines and their mates on the spindle. If the crank arm splines are damaged the arm can pivot back and forth on spindle and back the bolt out.

thank you