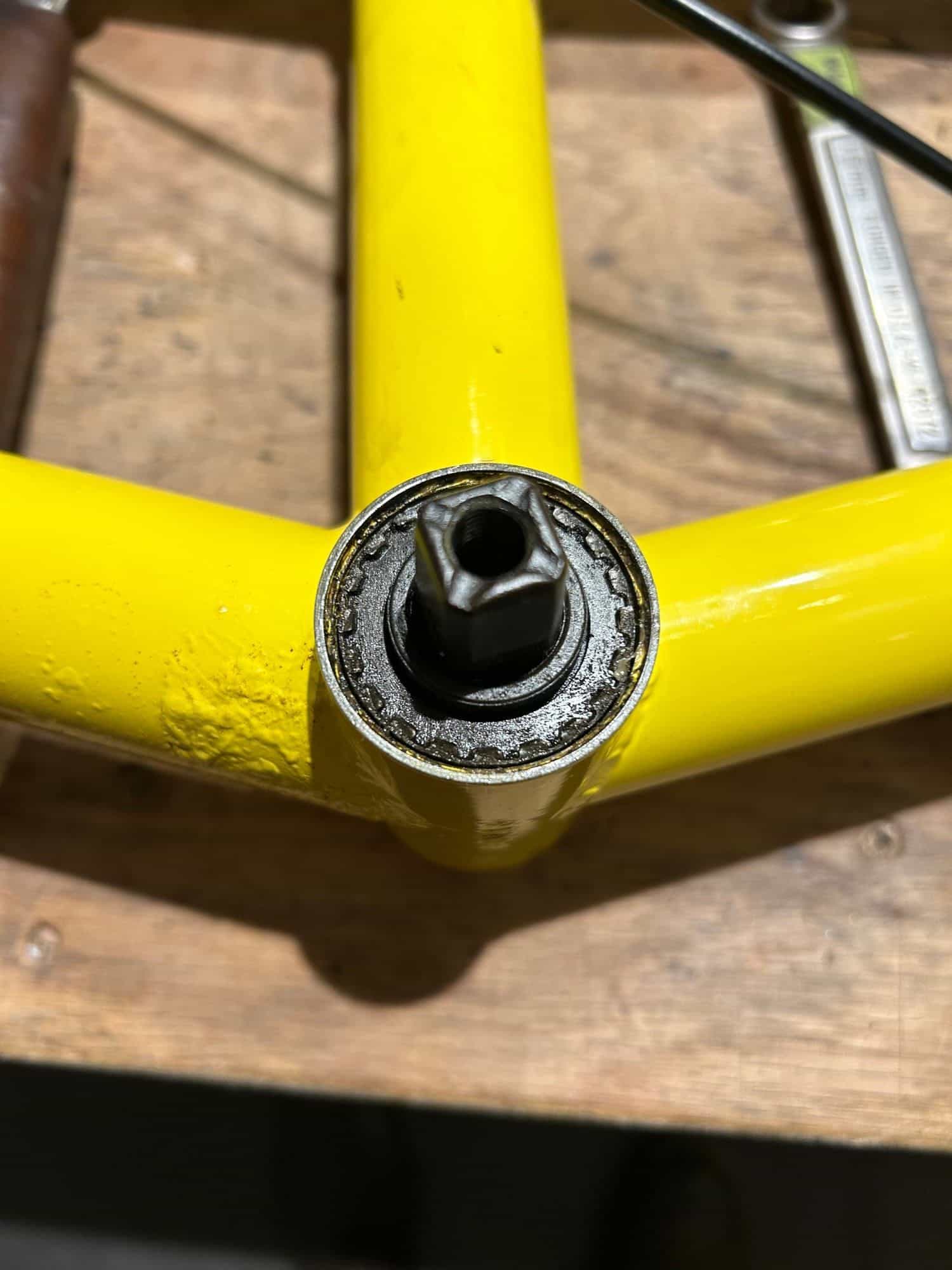

Very bad BB problem. seized and broken teeth.

#26

Senior Member

Join Date: Nov 2010

Location: Sacramento, CA

Posts: 22,998

Bikes: old ones

Liked 10,449 Times

in

7,248 Posts

https://www.bikeforums.net/g/user/548708/photos

So now what?

So now what?

The first think I would try, would be a combination of heating the BB on that side with a plumber's torch, and cooling it with Freeze off.

A couple of cycles of heating and cooling should at least break free any corrosive bonding in the threads. And he Freeze off contains a penetrating oil as well. It's flammable, so don't ignite the spray can. But don't worry if some of it flames off after the first cycle, when you heat for the second cycle.

Then, you need to buy a metric bolt at the hardware store, that has the same diameter and threading as the crank bolt. Take one along with you to match it up, and take along your tool. The bolt needs to be long enough to extend fom the end of the tool and reach in far enough to screw into the BB spindle. But it needs to be short enough that you can take up the excess length with a stack of fender washers, if it bottoms out before the tool is tight against the cup. So you also need to buy some wide fender washers, maybe 5 or 6, that will fit on the bolt.

After the heating and cooling, bolt the Shimano tool in place...firmly if you already have the other side removed. It needs to be locked down pretty tight, because you don't have much left in the way of teeth. Use a Crescent wrench on the outside of the square shaft of the Shimano tool, to turn it the correct way this time. I'm pretty sure this will work. If not, report back and get instructions on destructive removal, which is a lot more work and cursing.

Last edited by 3alarmer; 11-18-23 at 05:42 PM.

#29

Senior Member

Join Date: Nov 2010

Location: Sacramento, CA

Posts: 22,998

Bikes: old ones

Liked 10,449 Times

in

7,248 Posts

...no. If you drive out the spindle, you won't have anything to bolt to, with the special bolt and fender washers you bought at the hardware store.

If the spindle is gone, you need a longer bolt, that goes all the way from the outside end of the Shimao tool, to out past the other side of the BB shell.

Then you use fender washers on both sides, and a nut on the end of the bolt, to clamp the tool in place.

All of this is to just firmly hold that Shimano tool to the cup. Otherwise, they have a tendency to jump out when you apply torque, even with all the teeth remaining.

If the spindle is gone, you need a longer bolt, that goes all the way from the outside end of the Shimao tool, to out past the other side of the BB shell.

Then you use fender washers on both sides, and a nut on the end of the bolt, to clamp the tool in place.

All of this is to just firmly hold that Shimano tool to the cup. Otherwise, they have a tendency to jump out when you apply torque, even with all the teeth remaining.

Likes For 3alarmer:

#30

Senior Member

Join Date: Nov 2010

Location: Sacramento, CA

Posts: 22,998

Bikes: old ones

Liked 10,449 Times

in

7,248 Posts

#31

Senior Member

Join Date: Nov 2010

Location: Sacramento, CA

Posts: 22,998

Bikes: old ones

Liked 10,449 Times

in

7,248 Posts

Likes For oneclick:

#33

Huge +1 on the turning of the tool. Also something that can help before it is stripped out is an impact gun, I wouldn't use it for a tightening role and wouldn't use it too often for loosening but it can really help on those tough ones. Most people probably would abuse it so be wise it is not really a bicycle tool but can be really helpful in these small instances and then for the future put plenty of grease in there.

#34

Senior Member

#35

Clark W. Griswold

Join Date: Mar 2014

Location: ,location, location

Posts: 14,065

Bikes: Foundry Chilkoot Ti W/Ultegra Di2, Salsa Timberjack Ti, Cinelli Mash Work RandoCross Fun Time Machine, 1x9 XT Parts Hybrid, Co-Motion Cascadia, Specialized Langster, Phil Wood Apple VeloXS Frame (w/DA 7400), R+M Supercharger2 Rohloff, Habanero Ti 26

Liked 4,261 Times

in

2,848 Posts

I always thought they were just for cars, but I recently stripped an old bike and found the rattle gun invaluable for removing the fixed cup and crank bolts - you can use it with the bike held in a regular work stand, and you can easily hold the tool in place with little risk of it falling off. As for grease, on this bike someone had applied liberal amounts of sticky white goop that had solidified, I think that's why I had to use the impact driver.

You should remove and reinstall stuff every so often especially on a used bike of unknown origins with a bike you build yourself you know how you did things and can get a better sense but waiting to take of a bottom bracket or seat post or something can be quite bad if that person didn't install correctly.

Likes For veganbikes:

#36

Full Member

If you can't eventually get that bottom bracket out with a tool and it is definitely, for sure stuck, here's how I got out of the same situation.

A few years ago, I was in the same boat. Rusted in place bottom bracket that all of the teeth stripped out of it (and yes, I was turning it the correct direction). It was an early cartridge BB, UN60 if memory serves. I was able to get the spindle and all of the bearings out with a combination of a drill and hammer. using the drill to tear up the bearing cage and the hammer to force the spindle out. I probably used a skinny screwdriver to get all of the ball bearing to one side. Once the spindle and balls were out and I was left with just the outer shell, I went to town VERY CAREFULLY with a dremel with a cutoff wheel. It took a while, but enough creative cutting into the shell and breaking off chunks at a time got it all out. Wasn't a pretty process but no damage to the outside of the frame and only nicked the BB threads a few times. Chased the threads and it was good to go.

A few years ago, I was in the same boat. Rusted in place bottom bracket that all of the teeth stripped out of it (and yes, I was turning it the correct direction). It was an early cartridge BB, UN60 if memory serves. I was able to get the spindle and all of the bearings out with a combination of a drill and hammer. using the drill to tear up the bearing cage and the hammer to force the spindle out. I probably used a skinny screwdriver to get all of the ball bearing to one side. Once the spindle and balls were out and I was left with just the outer shell, I went to town VERY CAREFULLY with a dremel with a cutoff wheel. It took a while, but enough creative cutting into the shell and breaking off chunks at a time got it all out. Wasn't a pretty process but no damage to the outside of the frame and only nicked the BB threads a few times. Chased the threads and it was good to go.

#37

Senior Member

Join Date: Jul 2015

Location: NW Oregon

Posts: 3,042

Bikes: !982 Trek 930R Custom, Diamondback ascent with SERIOUS updates, Fuji Team Pro CF and a '09 Comencal Meta 5.5

Liked 772 Times

in

558 Posts

I always thought they were just for cars, but I recently stripped an old bike and found the rattle gun invaluable for removing the fixed cup and crank bolts - you can use it with the bike held in a regular work stand, and you can easily hold the tool in place with little risk of it falling off. As for grease, on this bike someone had applied liberal amounts of sticky white goop that had solidified, I think that's why I had to use the impact driver.

let the freewheel spin to a stop on it's own....

#39

Senior Member

Join Date: Jan 2010

Location: se MIch.

Posts: 2,387

Bikes: 1938 claud butler,1983 Basso,teledyne titan,teocali super,nrs,1993 stumpjumper fsr,Paramountain,Paramount Buell(sold),4 banger,Zaskar LE,Colnago Master Ibex MTB,1987ish,.etc....

Liked 3,094 Times

in

1,544 Posts

stuck BB/

had the same issue.resorted to an older park bbt-22 & pedros tool holder.

#40

https://www.bikeforums.net/g/user/548708/photos

Photos in this album.

I think the original diagnosis is right: turned the cup the wrong way. Sheared off the teeth. So now what?

Photos in this album.

I think the original diagnosis is right: turned the cup the wrong way. Sheared off the teeth. So now what?

Alternatively weld the axle to the cup, and use a steel crank to turn the axle.

#41

Propane torch to heat the bottom bracket shell. Since you already have rust under the paint, charring that area isn't a big deal.

The key is to heat the entire BB shell as evenly as you can, without getting any really hot spots concentrated in one area.

Be careful. The paint will smoke as it burns. The grease may also smoke somewhat.

Don't overdo it. The idea is to make the BB shell expand without putting in enough heat to make the BB itself swell.

The key is to heat the entire BB shell as evenly as you can, without getting any really hot spots concentrated in one area.

Be careful. The paint will smoke as it burns. The grease may also smoke somewhat.

Don't overdo it. The idea is to make the BB shell expand without putting in enough heat to make the BB itself swell.

#42

This was the trick! $2.69 from the hardware store, 8x1.25 bolt. Washers. No heat required.

I feel pretty foolish. Long and varied mechanical background and I was turning THE WRONG WAY.

Turns out no mater how hard you turn something the wrong way, it doesn't get any looser.

Thank you all for the help! I am back in action!

I feel pretty foolish. Long and varied mechanical background and I was turning THE WRONG WAY.

Turns out no mater how hard you turn something the wrong way, it doesn't get any looser.

Thank you all for the help! I am back in action!

#43

SE Wis

Join Date: Apr 2005

Location: Milwaukee, WI

Posts: 10,572

Bikes: '68 Raleigh Sprite, '02 Raleigh C500, '84 Raleigh Gran Prix, '91 Trek 400, 2013 Novara Randonee, 1990 Trek 970

Liked 3,428 Times

in

2,076 Posts

This was the trick! $2.69 from the hardware store, 8x1.25 bolt. Washers. No heat required.

I feel pretty foolish. Long and varied mechanical background and I was turning THE WRONG WAY.

Turns out no mater how hard you turn something the wrong way, it doesn't get any looser.

Thank you all for the help! I am back in action!

I feel pretty foolish. Long and varied mechanical background and I was turning THE WRONG WAY.

Turns out no mater how hard you turn something the wrong way, it doesn't get any looser.

Thank you all for the help! I am back in action!