Hunt carbon rim exploded while inflating

#76

Senior Member

Join Date: Aug 2009

Posts: 2,395

Mentioned: 14 Post(s)

Tagged: 0 Thread(s)

Quoted: 1562 Post(s)

Liked 1,734 Times

in

974 Posts

At least the OP wasn't just calling out Hunt for a bad wheel when it does appear the OP blew it...literally and figuratively.

Glad that Hunt send the OP a replacement rim...they just could have said 'sucks for you, next time read the owners manual' or some such wording.

Love the stories about 'asplosions'...keep them coming.

Glad that Hunt send the OP a replacement rim...they just could have said 'sucks for you, next time read the owners manual' or some such wording.

Love the stories about 'asplosions'...keep them coming.

My guess is that Hunt has to make the shelf area tighter than normal, because there is no bead to keep the tire from lifting off. That bead has to be tight against the rim shelf to prevent air pressure from prying underneath the tire bead. This tight construction, in turn means you need much higher pressure to seat the bead. But the weak hookless sidewall cannot stand the higher pressure. So now you have a death spiral.

Likes For icemilkcoffee:

#77

Senior Member

Yep, hoop stresses. I spread a double-walled aluminum rim that way once.

Likes For BlazingPedals:

#78

Senior Member

Not all of us are luddites.

I ride all three types of bikes - carbon, aluminum and steel.

I have aluminum and CF wheels.

I have rim and disc brakes, and I like the discs better.

Assploding CF is the only thing thatís put me in the hospital.

So Iím cautious about what parts and the type of parts I ride, pain will do that to you.

Oh and yes, my high end steel bike is awesome.

I ride all three types of bikes - carbon, aluminum and steel.

I have aluminum and CF wheels.

I have rim and disc brakes, and I like the discs better.

Assploding CF is the only thing thatís put me in the hospital.

So Iím cautious about what parts and the type of parts I ride, pain will do that to you.

Oh and yes, my high end steel bike is awesome.

Some people have a tendency to go to extremes in their hope to substantiate their argument but end up comparing proverbial oranges and apples. Use of CF in jets produced for our war department was thrown in by someone as the proof of materialís reliability - Iím not sure that the level of testing and quality control applied by bicycle companies will approach that of leading aerospace and war industry, such as Lockheed Martin etc. Of course, this is just a guess, may be bicycle industry perfected the technology and Lockheed Martin copied it. 😉

I have good quality frames made from steel, titanium, aluminum, and yes CF. They all work satisfactorily and admirably well for the purpose they were made and built up.

#79

Grupetto Bob

Join Date: Sep 2020

Location: Seattle-ish

Posts: 6,226

Bikes: Bikey McBike Face

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 2585 Post(s)

Liked 5,648 Times

in

2,924 Posts

A quick defense of Hunt carbon rims since they all don’t explode. Have had a pair of 60 mms for two years and have put on three sets of tires - using a compressor to seat the them. Don’t know the pressure used, but enough to get them in place, and never an issue.

__________________

Road 🚴🏾♂️ & Mountain 🚵🏾♂️

Road 🚴🏾♂️ & Mountain 🚵🏾♂️

Likes For rsbob:

#80

Advocatus Diaboli

Join Date: Feb 2015

Location: Wherever I am

Posts: 8,640

Bikes: Merlin Cyrene, Nashbar steel CX

Mentioned: 14 Post(s)

Tagged: 1 Thread(s)

Quoted: 4737 Post(s)

Liked 1,533 Times

in

1,004 Posts

#81

Banned

Join Date: Feb 2008

Location: Mississauga/Toronto, Ontario canada

Posts: 8,721

Bikes: I have 3 singlespeed/fixed gear bikes

Mentioned: 30 Post(s)

Tagged: 0 Thread(s)

Quoted: 4227 Post(s)

Liked 2,488 Times

in

1,286 Posts

Improper spoke tension is the main cause of metal fatigue on alloy rims...A properly built wheel especially if it's a disc wheel where brake track wear isn't an issue will last forever, unless it is crashed badly or seriously abused.

#82

climber has-been

Join Date: Dec 2004

Location: Palo Alto, CA

Posts: 7,111

Bikes: Scott Addict R1, Felt Z1

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 3432 Post(s)

Liked 3,567 Times

in

1,793 Posts

Everything we know about material science says that is untrue. Use an aluminum rim long enough, it will eventually fail from fatigue.

#83

With a mighty wind

Join Date: May 2015

Posts: 2,595

Mentioned: 13 Post(s)

Tagged: 0 Thread(s)

Quoted: 1088 Post(s)

Liked 862 Times

in

490 Posts

So there is that.

#84

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,909

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4806 Post(s)

Liked 3,932 Times

in

2,557 Posts

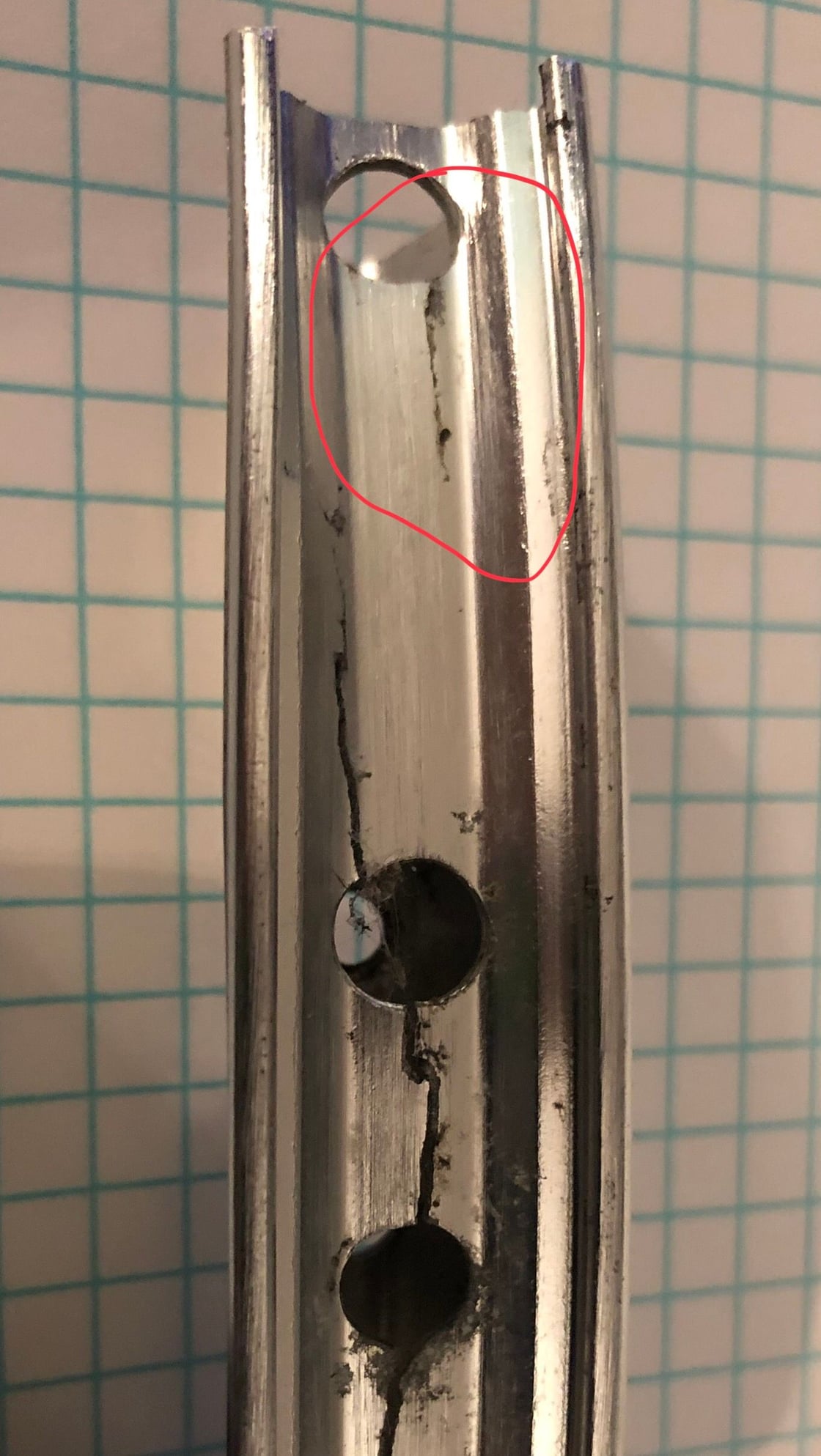

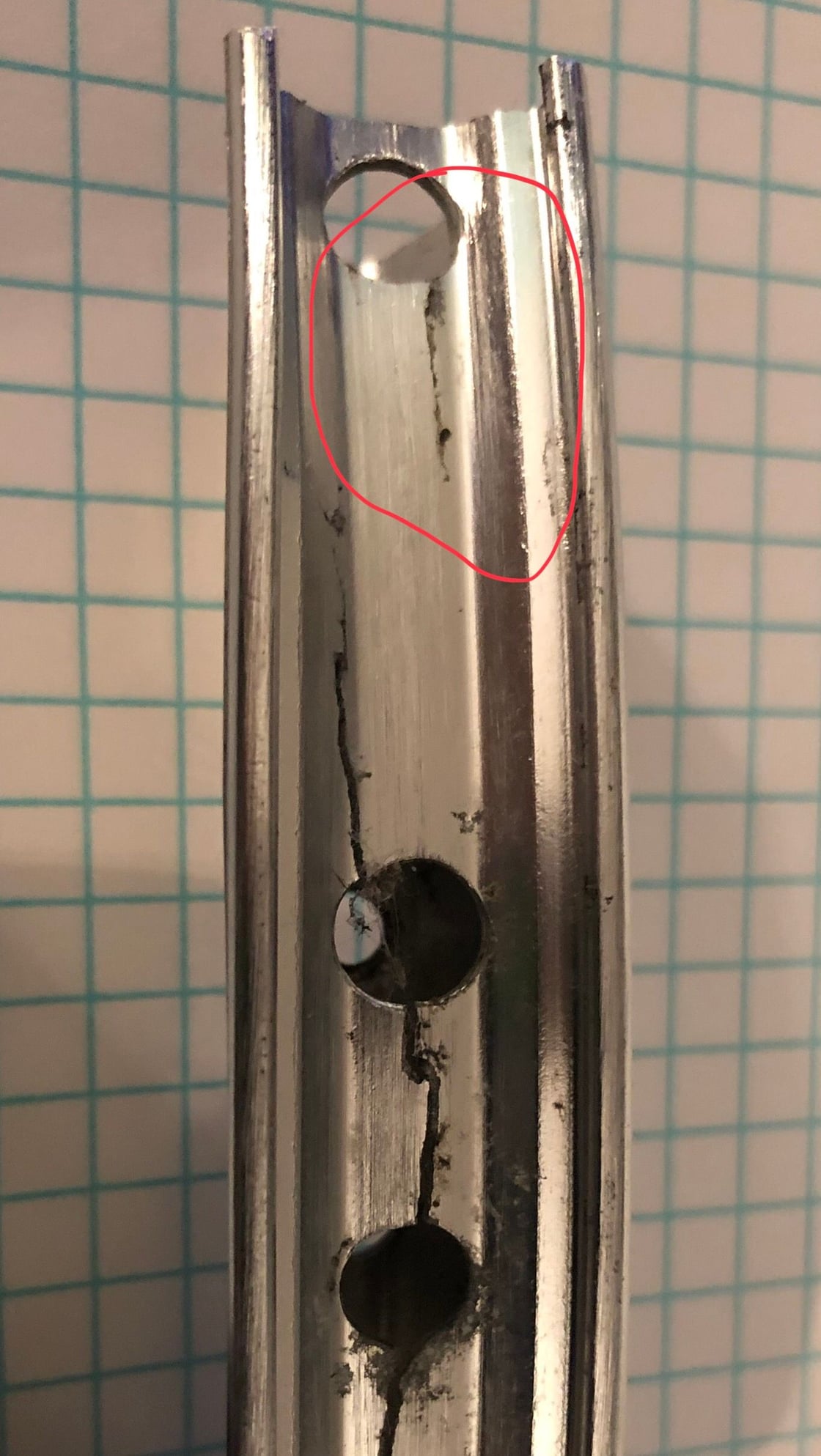

My experience agrees with this with the exception of several 20" (406) aluminum rims on the rear wheel of my folding commuter bike which failed along the center plane. I originally thought these were brake track wear failures which propagated into the rim. Eventually I showed these to Bill Mould, and was told these were more likely caused by high pressure (60psi) in wide (47mm) tires on relatively narrow rims. These were Kinetix rims, and while I can't say the rims were the problem, I did solve the problem by changing to Sun Ringle rims which are slightly wider.

For reference, I weigh about 215 pounds.

Rim failure from hoop stress. Brake tracks were about 1mm thick.

Rear brake was thumping when applied.

Another rim with hoop stress failure.

For reference, I weigh about 215 pounds.

Rim failure from hoop stress. Brake tracks were about 1mm thick.

Rear brake was thumping when applied.

Another rim with hoop stress failure.

#85

Senior Member

Join Date: Sep 2004

Location: Chicago area

Posts: 2,555

Bikes: Airborne "Carpe Diem", Motobecane "Mirage", Trek 6000, Strida 2, Dahon "Helios XL", Dahon "Mu XL", Tern "Verge S11i"

Mentioned: 23 Post(s)

Tagged: 0 Thread(s)

Quoted: 980 Post(s)

Liked 584 Times

in

401 Posts

Brake tracks were at least 1.0mm thick, and spoke tensions were all within 20% of the mean tension (at the time of building). I initially thought this was brake track wear that spread inward, but the rims weren't very worn and Bill Mould knows more about rims than I do, so I'm willing to accept that interpretation. In any case, the problem is licked.

#86

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,909

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4806 Post(s)

Liked 3,932 Times

in

2,557 Posts

Brake tracks were at least 1.0mm thick, and spoke tensions were all within 20% of the mean tension (at the time of building). I initially thought this was brake track wear that spread inward, but the rims weren't very worn and Bill Mould knows more about rims than I do, so I'm willing to accept that interpretation. In any case, the problem is licked.

Likes For 79pmooney:

#87

Senior Member

Well, folks - it’s really not rocket-surgery (=rocket science + neurosurgery). All materials yield to pressure/force. The thinner the material, greater likelihood of failure, all else being equal.

The only reason my Al wheels seem indestructible is because I start with a slightly heavier rim of high quality, build it myself quite well using a sturdy set of hubs, 32H laced 2-cross with double butted SS spokes - and most importantly, even (very close to equal) tension on all spokes. One can easily true a wheel without equal tension on spokes but they will not stay true for very long.

I’m sure that if I have someone weighing twice as much as I do, the bike and the wheels will survive… for a while, but wouldn’t prove indestructible in the long-run.

Im sure very similar principles apply to CF rims/wheels.

Given enough time, everything gets weaker and eventually fails. Things that built well will last a life-time of a person but it doesn’t mean they will never fail.

The only reason my Al wheels seem indestructible is because I start with a slightly heavier rim of high quality, build it myself quite well using a sturdy set of hubs, 32H laced 2-cross with double butted SS spokes - and most importantly, even (very close to equal) tension on all spokes. One can easily true a wheel without equal tension on spokes but they will not stay true for very long.

I’m sure that if I have someone weighing twice as much as I do, the bike and the wheels will survive… for a while, but wouldn’t prove indestructible in the long-run.

Im sure very similar principles apply to CF rims/wheels.

Given enough time, everything gets weaker and eventually fails. Things that built well will last a life-time of a person but it doesn’t mean they will never fail.

#88

Senior Member

Join Date: May 2008

Location: Zang's Spur, CO

Posts: 9,083

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 3376 Post(s)

Liked 5,522 Times

in

2,862 Posts

Some years back I learned the hard way that a larger cross-section on a tire increases stress on the rim,

when I cracked the sidewall of an aluminum rim...twice.

I broke the first rim, moved the hub & spokes to a new rim, then that one broke a couple months later.

Failure was where the bead of the rim met the inner rim wall, pressure was at max rating of a 1.9" tire.

So I did some digging. (PDF)

Understanding the Influence of Pressure and Radial Loads on Stress and Displacement Response of a Rotating Body: The Automobile Wheel

See page 3, Section "2.2. Influence of tire air pressure".

when I cracked the sidewall of an aluminum rim...twice.

I broke the first rim, moved the hub & spokes to a new rim, then that one broke a couple months later.

Failure was where the bead of the rim met the inner rim wall, pressure was at max rating of a 1.9" tire.

So I did some digging. (PDF)

Understanding the Influence of Pressure and Radial Loads on Stress and Displacement Response of a Rotating Body: The Automobile Wheel

See page 3, Section "2.2. Influence of tire air pressure".

Likes For Shimagnolo:

#90

With a mighty wind

Join Date: May 2015

Posts: 2,595

Mentioned: 13 Post(s)

Tagged: 0 Thread(s)

Quoted: 1088 Post(s)

Liked 862 Times

in

490 Posts

So I find this thread enlightening.

Ive been on bikes in a semi serious to way too serious capacity since the early 90ís.

In that time, this simply has never come up for me. To be fair, my super serious years were spent on 20 and 23c tires, often glued on. So a totally different story.

Still, Iíve got a load of gravel and mountain bikes now. All tubeless. I would have never thought that the lower of either the rim max pressure or tire max pressure could destroy a rim, based on tire size. Seems like a more detailed rim sticker would be an easy fix.

I think Iím probably like most of us, itís never happened to me before only because my tires feel pretty firm around 40-45psi. Not because I knew any better.

Ive been on bikes in a semi serious to way too serious capacity since the early 90ís.

In that time, this simply has never come up for me. To be fair, my super serious years were spent on 20 and 23c tires, often glued on. So a totally different story.

Still, Iíve got a load of gravel and mountain bikes now. All tubeless. I would have never thought that the lower of either the rim max pressure or tire max pressure could destroy a rim, based on tire size. Seems like a more detailed rim sticker would be an easy fix.

I think Iím probably like most of us, itís never happened to me before only because my tires feel pretty firm around 40-45psi. Not because I knew any better.

Likes For rosefarts:

#91

Senior Member

Join Date: Jan 2010

Posts: 39,254

Mentioned: 211 Post(s)

Tagged: 1 Thread(s)

Quoted: 18424 Post(s)

Liked 15,580 Times

in

7,337 Posts

Either that, or heís clueless.

Likes For indyfabz:

#92

Senior Member

Join Date: Jul 2009

Posts: 5,954

Bikes: Colnago, Van Dessel, Factor, Cervelo, Ritchey

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 3956 Post(s)

Liked 7,308 Times

in

2,949 Posts

#93

Senior Member

Join Date: Dec 2019

Location: 757

Posts: 11,255

Bikes: Madone, Emonda, 5500, Ritchey Breakaway

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 10238 Post(s)

Liked 5,185 Times

in

2,226 Posts

Damn, I mounted my hunt wheels the other day. I have never set up tubeless before and watched a bunch of youtube videos on it. The one thing I never saw was how to install the valve stem correctly. The videos just showed inserting and hand tight the little nut. So thatís what I did. 6 co2 cartridges later I couldnít get the bead to set fully. Gave up and took it to the shop to install.

Something that took me hours, took my buddy 5 mins.

Something that took me hours, took my buddy 5 mins.

#94

Senior Member

Join Date: Dec 2019

Location: 757

Posts: 11,255

Bikes: Madone, Emonda, 5500, Ritchey Breakaway

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 10238 Post(s)

Liked 5,185 Times

in

2,226 Posts

Should clarify, I did not push the valve stem in place while tightening the nut. I got 70 percent the tire to set but couldnít get the rest of it.

#95

Senior Member

Join Date: Aug 2009

Posts: 2,395

Mentioned: 14 Post(s)

Tagged: 0 Thread(s)

Quoted: 1562 Post(s)

Liked 1,734 Times

in

974 Posts

the valve stem should definitely be pushed down firmly while you tighten the ring nut.

#96

Senior Member

Join Date: Dec 2019

Location: 757

Posts: 11,255

Bikes: Madone, Emonda, 5500, Ritchey Breakaway

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 10238 Post(s)

Liked 5,185 Times

in

2,226 Posts

#97

Senior Member

Join Date: Jan 2010

Posts: 39,254

Mentioned: 211 Post(s)

Tagged: 1 Thread(s)

Quoted: 18424 Post(s)

Liked 15,580 Times

in

7,337 Posts

#98

Senior Member

Join Date: Dec 2019

Location: South Shore of Long Island

Posts: 2,800

Bikes: 2010 Carrera Volans, 2015 C-Dale Trail 2sl, 2017 Raleigh Rush Hour, 2017 Blue Proseccio, 1992 Giant Perigee, 80s Gitane Rallye Tandem

Mentioned: 12 Post(s)

Tagged: 0 Thread(s)

Quoted: 1088 Post(s)

Liked 1,026 Times

in

723 Posts

I find this conversation to be very informative as I'd always assumed that 100psi is a 100psi and if that's what a rim is rated for than why would the tire matter. Still not fully getting it as the amount of material in contact with the rim would seem to be the same regardless of the tire size, either way its the same amount of tire contact at the bead as well as the same amount of pressure contained within the system, So is it ultimately a leverage situation? The way the tire expands pushes out on the rim differently effecting how the stress of holding the tire is placed on the rim? Cause I read the amount of area being an issue but I don't see how a larger tire has any more area in contact with the rim. The larger tire has a larger cross section obviously but it would seem to me that there can't be any additional amount air in contact with the rim as the bigger tire does nothing to change the amount of surface area of the rim the tire/tube/air can act upon. How can any size tire with a 100psi apply more pressure than 100psi onto the rim other than by increasing the load on the tire?

I've seen aluminum rims in cross races shattered, a lady walked off the course with her rim cracked into 4 separate pieces and rims split width wise from trick riding, so there's plenty of ways an alloy rim could fail.

I've seen aluminum rims in cross races shattered, a lady walked off the course with her rim cracked into 4 separate pieces and rims split width wise from trick riding, so there's plenty of ways an alloy rim could fail.

Likes For Russ Roth:

#99

Method to My Madness

Join Date: Nov 2020

Location: Orange County, California

Posts: 3,664

Bikes: Trek FX 2, Cannondale Synapse, Cannondale CAAD4, Santa Cruz Stigmata GRX

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 1948 Post(s)

Liked 1,472 Times

in

1,020 Posts

I find this conversation to be very informative as I'd always assumed that 100psi is a 100psi and if that's what a rim is rated for than why would the tire matter. Still not fully getting it as the amount of material in contact with the rim would seem to be the same regardless of the tire size, either way its the same amount of tire contact at the bead as well as the same amount of pressure contained within the system, So is it ultimately a leverage situation? The way the tire expands pushes out on the rim differently effecting how the stress of holding the tire is placed on the rim? Cause I read the amount of area being an issue but I don't see how a larger tire has any more area in contact with the rim. The larger tire has a larger cross section obviously but it would seem to me that there can't be any additional amount air in contact with the rim as the bigger tire does nothing to change the amount of surface area of the rim the tire/tube/air can act upon. How can any size tire with a 100psi apply more pressure than 100psi onto the rim other than by increasing the load on the tire?

What is the ideal gas law? (article) | Khan Academy

A wider tire has greater Volume (than a narrower tire). Thus, at the same Pressure and Temperature, the wider tire also contains a greater number of moles (i.e., amount) of air than a narrower tire.

All of the air within the tire exerts a force against the sidewalls of the wheel via the tire, not just the air at the boundary of the tire and wheel. If you don't believe me, you can do this experiment: Mount a 700x25c tire and a 700x32c tire to the same wheel and inflate each to the same pressure, and see which tire feels firmer?

This is confirmed by the Hoop Stress formula: Pressure Vessel, Thin Wall Hoop and Longitudinal Stresses Equation and Calculator (engineersedge.com)

... which shows that at the same Pressure, Hoop Stress increases with the cross-sectional diameter of the tire, which is proportional to Volume.

Likes For SoSmellyAir:

#100

Senior Member

Join Date: May 2008

Location: Zang's Spur, CO

Posts: 9,083

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 3376 Post(s)

Liked 5,522 Times

in

2,862 Posts

IStill not fully getting it as the amount of material in contact with the rim would seem to be the same regardless of the tire size, either way its the same amount of tire contact at the bead as well as the same amount of pressure contained within the system, So is it ultimately a leverage situation? The way the tire expands pushes out on the rim differently effecting how the stress of holding the tire is placed on the rim? Cause I read the amount of area being an issue but I don't see how a larger tire has any more area in contact with the rim. The larger tire has a larger cross section obviously but it would seem to me that there can't be any additional amount air in contact with the rim as the bigger tire does nothing to change the amount of surface area of the rim the tire/tube/air can act upon. How can any size tire with a 100psi apply more pressure than 100psi onto the rim other than by increasing the load on the tire?

.

.

All explained on page 3 of that document.

Look at Figure 4 and Equation 5.

"a" is the overall radius of the tread of the inflated tire.

"rf" is the radius of the rim at the inner surface of the bead.

Assuming the tire has a round cross-section when inflated: a - rf = <width of tire>

Now think about varying "a" by changing tire width;

As "a" becomes closer to "rf" (narrower tire), the lateral force on the rim decreases.

As "a" becomes further from "rf" (wider tire), the lateral force on the rim increases.